The article describes the advantages that the TechnoNIKOL vapor barrier has, its purpose is indicated, and its every characteristic is given. Anyone who studies the proposed material will understand where and how to use the described films, the video will reveal the technical features of the material.

Positive and negative properties of the described material

Today the vapor barrier for the roof from the company "TechnoNIKOL" is very popular. The manufacturer described is a representative of large business, its plants are located not only in Russia, but also in the countries of near and far abroad. Manufactured products meet the highest quality standards, have certificates of compliance with European standards, while it is in the mainstream segment. These ingredients are not the only benefits.

Additional positive characteristics include:

-

High strength , materials have a high stretch ratio, so it is quite difficult to break the proposed films.

-

They do not burn when exposed to an open flame.

-

Colonies of fungi and molds do not settle on them.

-

Materials do not allow moisture and steam .

There is only one drawback to the vapor barrier “TechnoNIKOL”: most of the proposed films do not withstand the effects of direct sunlight. They heat it up, as a result, the vapor barrier spreads and loses its properties. Therefore, when mounting the film stacked between the layers of roofing material and insulation.

Purpose and types

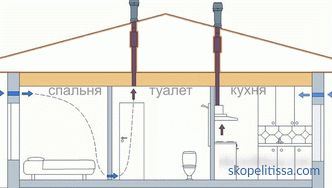

Technical characteristics of the vapor barrier from "TechnoNIKOL" define the scope its application. The described material is superimposed over the insulation, it helps to protect it from condensation that forms indoors during its operation. In this way, builders are trying to prevent the wetting of individual layers of the “roofing pie” and extend the service life of the insulation. The use of para-insulating films also prevents the appearance of mold and fungi, as well as an unpleasant, musty smell.

Films are used directly during the roof installation process. The manufacturer described offers several types of vapor barrier films. Each has its own specifications.

On our site you can find contacts of construction companies that offer services to design and repair roofing . Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

So, for example, films intended for the skates of the blood partially miss the steam. Vapor barrier for flat blood can boast the highest levels of strength and elasticity. Reinforced strips consist of three layers. Such a structure helps to form the high strength of the web material. The physicomechanical properties of universal films are unique. Such materials can be used for the insulation of the roof, walls and ceiling.

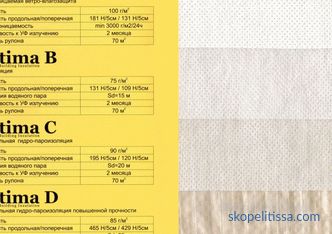

The product from the Optima series

Such films are a three-layer material. The upper and lower base is made of polypropylene non-woven base, the middle layer is a vapor barrier membrane. A similar vapor barrier is used to protect fiber insulation. Its use allows you to provide indoor climate in its technical characteristics close to the climate of a log house. Such properties are relevant if the space under the roof is used as a living space. Materials from the Optima series are actively used when creating ventilated facades, and when performing internal wall and floor insulation.

The membrane works as follows:

-

moisture vapor penetrates through the lower layer and lasts on average;

-

some of them come out through the upper layer and dissolve in the environment .

Such a feature of the vapor barrier “work” allows the insulated surface to “breathe”. The material is produced in rolls, the width of one is one and a half meters. Experts draw attention to the fact that such a product can be used as wind protection in those regions where the climate demonstrates its instability.

It might be interesting! In the article the following link read about ondulin roof: description and material characteristics, installation methods .

The vapor barrier for a flat roof from TechnoNIKOL has two functions.On the one hand, it protects the roof insulation against possible penetration of moisture through the roof covering, on the other hand, it prevents the formation of condensate from the side of the flat roof elements. The structure of the material consists of three layers. All of them are made of polyethylene. In contrast to Otptimi, this film has a higher vapor permeability index, while its thickness is twice as small. It is important to understand that the vapor barrier film for flat blood from "TechnoNIKOL" has a narrow scope. It can not be used, conducting warming cattle roof. In such a situation, it will not be able to provide adequate protection from precipitation. Therefore, mainly the described material is used in private construction, it is useful in the construction of pre-fabricated structures.

Reinforced vapor barrier also consists of three layers. Its basis is a film reinforced by interlacing durable strips formed of polyethylene. A laminated polyethylene film is placed on top of it and below. This structure allows you to create a roll material that can demonstrate improved stability. Lamination enhances the properties of vapor permeability.

Such a film is produced in the form of rolls, the width is one and a half meters. It is very durable, it has a long operating time, is not subject to rotting and mold. It can be used for warming attic, sloping roofs, sloping and flat structures. Reinforcement significantly expands the scope of application. It contributes to the retention of heat, so its second purpose - additional insulation.

Polyethylene does not let moisture through. When choosing such a vapor barrier, it is important to remember that its use significantly increases the weight of the insulation. Therefore, where there are weight restrictions, reinforced vapor barrier is not used. Most often, with the help of it, a "pie" of insulation is created, when polystyrene foam or polystyrene acts as a heat insulator.

Reinforced film has another type. This is a windproof film. Its scope is to protect flat surfaces from moisture and dust. The manufacturer recommends using it where the slopes of the roofs are ventilated. It is considered expedient to choose a wind-proof film for arranging ventilated facades.

It may be interesting! In the article on the following link read about proper control over the construction progress - technical supervision .

Features of vapor barrier installation

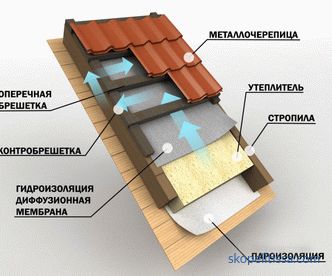

The installation of insulation of various structural elements has its own distinctive sides. If you are warming the internal surfaces, rolls of "TechnoNIKOL" should be placed on the inside of the insulation overlap. Joints are additionally sealed with mounting tape. Fastened material on the crate. To do this, use staples of medium size or dowel nails made of galvanized sheet with a head that looks like a mushroom cap. Along the edges of the vapor barrier is displayed on the surface adjacent to the heater for 30 cm. On top of it is a counter crate. It helps to create the gap needed to provide ventilation between the insulation and the finish.

The video shows how the masters correctly install the vapor barrier film on the insulated wall:

The vapor barrier of the non-insulated roof is made as follows. The rolls of "TechnoNIKOL" roll right on the rafters and fasten to them with the help of special construction brackets. Strips from the eaves begin to be laid and stretch up to the ridge of the roof. Every second fit overlap. It should be at least 15 cm. When rolling a vapor barrier, you need to carefully monitor that creases or folds do not form. They will then contribute to the accumulation of condensate. Over the top of the batten are fastened, and installation of the roofing material is already carried out on them.

When conducting external insulation, reinforced vapor barrier is used. It is mounted in any direction (horizontal or vertical), but always on top of the insulation. You can lay out the roll from any side. The joints are additionally fastened with tape. Where the seams are adjacent to the lath structure, they are further sealed with assembly foam. It is important throughout the installation of the film to ensure that the integrity of the protective coating is preserved and to prevent its rupture during attachment and tension.

If a double-sided film is used, in which one side is rough and the other is smooth, the one that has a smooth surface unfolds on the insulation. This is done to ensure that condensate, which will always accumulate on the surface of the vapor barrier, has the ability to evaporate. If one side of the film is foil, it should look foil out.In this position, it will effectively reflect the sun's rays.

When laying films on vertical surfaces, you need to ensure that the joints fall on the batten strips.

The video shows how to properly install the vapor barrier on the roof structure:

It might be interesting! In the article on the following link read about summer house with a porch .

Generalization on the topic

Experts say that the vapor barrier films from the manufacturer described meet all the requirements of vapor barrier. They meet all existing requirements, are of high quality, while the material itself is available. It can be purchased at any specialty store.