The article describes how the warming of the frame house is carried out outside under the siding. It is considered which insulation can be used, as well as the step-by-step process of laying the insulation material and the frame for siding. If you understand the information received, you will understand what and why the masters do and will be able to ask the right questions when discussing the work and selecting materials.

What is a siding

This is a material for exterior wall cladding whose purpose is to protect the walls from natural loads (rain, snow, wind, etc.), plus decorate them. The modern building materials market today offers several siding inputs:

-

polyvinyl chloride vinyl;

-

galvanized iron metal sheet up to 0.8 mm thick, painted or decorated for different building materials;

-

wooden, this is a type of lining;

-

cement, decorated as stone;

-

ceramic.

The last two are heavy materials, so they try not to use them for frame houses.

Insulation for siding

It is necessary to immediately indicate that the whole structure Siding installation is a ventilated facade. That is, it is a frame that is attached to the wall of the house at a short distance. To him, respectively, and fasten the panels themselves siding. The gap between the facing and the surface of the wall is left specially so that the wet vapors do not settle on the wall planes, but are brought out of the building.

It is this gap that allows you to install a heat-insulating layer. At the same time, the insulation is selected in thickness in such a way that a small air gap is additionally left between the siding and the heat-insulating cake. That is, the ventilated facade will even perform its functions in this form.

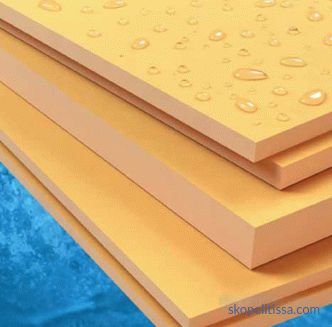

When choosing how to insulate a house outside under the siding, most often pay attention to two materials that are recommended for the insulation of wooden houses outside. This is mineral wool in mats and polystyrene foam plates (better extruded). With expanded polystyrene everything is clear. It is durable, with a high coefficient of moisture resistance, hydrophobic (that is, not absorbent). Its only drawback is the material that supports combustion and belongs to the burning class G3 and G4, depending on its density.

As for mineral wool, this material is hydrophobic. And this is his only drawback. Therefore, when installing mineral wool on ventilated facades, protective films are used, protecting the insulation from the negative effects of high humidity. But this drawback is also eliminated by manufacturers who today produce moisture resistant mineral wool. It does not have to be protected from moisture.

The mineral wool has one property that distinguishes it from the whole range of thermal insulation materials. This is one hundred percent non-flammable, which relates it to the "NG" class. Therefore, who is going to carry out the warming of a log house outside under the stone wool siding, our recommendations. You will not find a better option. This applies not only to the log houses, but also to all structures erected from wood, which also includes frame structures.

As for the price component, mineral wool and polystyrene foam plates differ in cost from each other. For example, the average price of a mineral wool with a thickness of 100 mm per 1 m² is 1000 rubles. Polystyrene plates of the same size - an average of 1200-1500 rubles.

On our website you can find contacts of construction companies that offer the service of calculating and performing work on weatherization of houses key. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Technology of installation of insulation

So, to insulate a house with siding, it is necessary to build a framework on the walls first of all. But previously everything is removed from the wall surfaces that will interfere with the installation process: gutters, shutters, grilles and other accessories. After that, wooden surfaces are treated with antiseptic and flame retardant compounds. The first protects the wood from the appearance of harmful microorganisms, the second from fire. Put compositions with a brush, roller or spray.

Construction of the frame of the ventilated facade

First of all, it is determined what thickness the insulation will be used for the insulation layer. For wooden buildings it is 100 mm. Therefore, the gap between the siding and the walls of the house will be slightly more than this figure, approximately 2-5 cm.

As for the material from which the framework of the ventilated facade is being constructed, there are two options:

-

wooden bars with a section of 50x50 mm;

-

metal profile, which is used for the installation of drywall.

For many reasons, the second option is better than the first. Metal under the influence of changes in street humidity and temperature does not warp, does not rot and does not change its size. True, this is a more expensive option. But experts recommend using it. By the way, in the frame used rack profile "PS" with dimensions or 50x50 or 50x75 mm.

Heater and frame elements are selected and purchased. Now you need to make a markup on the wall The basis of the parameters of the frame is the length of the siding. There is a fairly large size range depending on the raw material and technical conditions of production. For example, metal siding is produced with a length of up to 8 m, vinyl within 2.5-3.8 m, wooden - 3 m. It is important that the two adjacent panels are joined on the same profile. And already under each siding products, several frame profiles are installed. The main thing is that the facing panels do not bend. Therefore, the optimal installation step of the vertical frame posts is 1-1.5 m.

On our site you can familiarize yourself with the most popular projects of houses that were used to finish ventilated facade technology - from construction companies represented at the “Low-Rise Country” houses exhibition.

But there is one subtlety here. If the wall in its design does not have windows and doors, then markup is applied from any angle to the opposite with the step indicated above. If windows and doors are present, then markup is carried out from their edges. That is, the edges of the mounting openings of the frame stand must be present. Therefore, in these places on the walls cause vertical lines. And then from them to the right and left lay lines with a step of 1-1,2 m.

The rack-to-wall profile is fixed to the walls of the wooden house with the help of direct suspensions. The latter are installed on the printed lines in increments of 0.5-1 m. They use for fixing screws on the tree.

You can clearly see the technology of the ventilated facade in the video:

Laying insulation

It may seem to many that the frame needs to be assembled . But in the technology of insulation of a wooden house under the siding, the next stage is the installation of heat-insulating material. It is simply placed on the wall from the bottom up, tightly pressing the plates or mats to each other. Then just as the adjacent rows are laid vertically.

If there are windows and doors on the wall, then they start laying from the edges of the openings. The main task of the manufacturer is to assemble insulation with whole plates around windows and doors. And at the edges of the walls (corners), lay the material clipped to the required dimensions. At the same time, installation at the windows starts from the bottom, filling the area from the opening to the foundation of the house.

As for the installed direct suspensions, in the places of their passage through the heater, in the latter they are made through holes. Heat-insulating material just put on fasteners. When the entire insulation layer is laid on the walls, they proceed to the installation of a metal profile. It is important that all elements are located in the same vertical plane.

-

Therefore, first install two racks in opposite corners of the building. They are set vertically, as well as horizontally among themselves.

-

Produce fastening racks to direct suspensions with metal screws (bugs) with self-tapping screws.

-

Tension between three or four rows of strong thread between established profiles.

-

Intermediate frame elements with attachment to suspensions are mounted along threads.

The skeleton for the ventilated facade is ready, the insulation has been laid, you can proceed to facing the walls with saidin.

It may be interesting! In the article on the following link read about the wet facade - the universal technology of building insulation.

A simple option for warming a frame house

Frame houses are practically ready-made structures, on the elements of which you can immediately lay siding. In fact, these are constructions of vertical posts, tied up with bottom and top beams. The photo below shows the frame of such a house.

To insulate such a house, you just need to lay the insulation material between the uprights with a thickness of 100 mm. After that, the vapor barrier is laid on the racks with horizontal stripes. Laying is carried out from the bottom up with the overlap of the upper bands on the bottom in the size of 10-15 cm. The joint is closed with self-adhesive tape.

After that, wooden slats with a cross section of 50x50 cm are vertically packed along the posts. They will create a ventilation gap between the insulation and the siding.And already on rails install and fasten siding to them.

How to insulate with mineral wool a frame house with veneer siding is shown in the video:

It can be interesting! In the article on the following link read about the modern, warm and cozy cottage in the Art Nouveau style on the ocean.

Conclusion on the

topic In fact, it should be noted that the technology of finishing the walls of houses with siding is simple. The whole question boils down to one thing - to properly assemble the frame. In the design of frame houses, there is even no need to do this, because the building itself is already intended to lay insulating material in its walls. Which simplifies the technology to a minimum. Nevertheless, we recommend paying special attention to the choice of insulation for the walls of a wooden house outside under the siding. As mentioned above, the optimal solution is mineral wool.