Every second a private house resists external factors, the most damaging of which is dampness. Groundwater, seeping inside, is able to change the microclimate in the premises; Salts dissolved in water change the structure of concrete and wood. Protection from high humidity should have the entire structure, including floors. Reliable waterproofing for the floor will avoid many troubles, among which the damaged carpet will be the most minor problem.

A more threatening symptom may be the appearance of an unpleasant odor, speaking of the development of fungus and the onset of decay. Frivolous attitude will lead to the need to replace the sexes. Concrete may also be subject to corrosion.

Floor waterproofing is extremely necessary in wet rooms

What is waterproofing (sealing) a floor

Waterproofing is called a set of measures to protect the premises and surfaces from the effects of moisture. They significantly extend the life of the materials and protect the health of the family living in the house. The actual measure is laying on the floor of the waterproofing layer; This is especially necessary where humidity often exceeds the norm (in bathrooms, saunas). In case of force majeure situations, a well-performed sealing of the floor will save the neighboring rooms from damage.

Requirements for waterproofing of floors

The strategy of waterproofing is regulated by many regulatory documents. During the work, it is necessary to follow the requirements of SNiP 3. 04. 01-87 (section 4, speaking about the device of the floors) and SNiP 2. 03. 13-88 (about the floors). In accordance with these documents, in the floor design of wet rooms (bathrooms, bathrooms, saunas), waterproofing is necessarily arranged.

Also, it would not be superfluous to get acquainted with the Instruction BCH-9-94 DS (device of floors in residential and public buildings) and the specifications of the materials used. By construction standards, floors in wet rooms are arranged a few centimeters below the main level of the other rooms. This technique allows you to retain water in a confined space and quickly eliminate the consequences. At the entrance is a step or a limiting curb.

Properly organized bathroom threshold

Types of insulation materials

All types of waterproofing materials can be divided by place of use - for outdoor or indoor. Also qualified by division by composition. Then they are called bituminous, polymeric, mixed (bitumen-polymer) and including mineral components.

In most cases, materials for waterproofing are conveniently distinguished by the method of application. The most effective and therefore popular are considered:

-

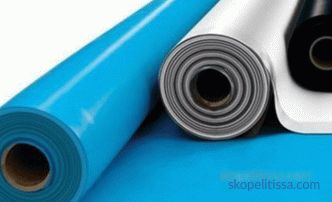

Roll, film (membrane, adhesive) materials ; including painting, coating, plastering compounds and mastics. Such options are optimal for those who want to work independently. Difficulties may arise with the high-quality installation and connection of the parts of the roll coating.

Roll materials - a reliable way to protect the floor

-

Penetrating (penetrating) waterproofing . Its use is accompanied by a number of conditions, in addition, when applying it is important to strictly follow the instructions.

-

Bulk waterproofing . The laborious option applied under a coupler. Upon contact with water, the granules form a gel (paste), stopping its further spread.

-

Self-leveling polymer floors (3D floors) . Capricious and unpredictable material for waterproofing the floor, if there is no practical experience and devices.

-

Sprayed polymeric coatings (polyurea) . For high-quality application requires experience, clothing and appropriate equipment.

On our website you can find contacts of construction companies that offer the service of designing houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

The nuances of choosing an insulating material and technology

Waterproofing the floor in an apartment and a private house is responsible not only for sealing, but also partially for ventilating the room. Attention to the selection of materials (as in any work) will help in the future to increase the energy efficiency of a private house with a corresponding saving of money.

Different ways of applying a waterproofing coating

When choosing various options, estimate future consumption (based on the area and nature of the premises) and the final cost . The opinion of a specialist with experience in arranging various types of isolation will be extremely useful.

Different rooms may require individual installation technology. To choose the best way, they take into account the peculiarities of the surface and the terms in which the work must be completed.

Preparatory work performed before waterproofing

Proper waterproofing of the floor in a wooden or brick house begins with preparation. The following measures are considered to be preparatory:

-

For large-scale repairs with redevelopment, partitions and other unnecessary elements are first dismantled.

-

The old floor covering is removed to the concrete base. In order not to reduce the quality of waterproofing, rusted and greasy areas are cleaned, construction debris is carefully removed.

Floor waterproofing using self-adhesive bitumen-polymer roll material on video:

It may be interesting! In the article on the following link read about the hydraulic accumulator for water supply systems.

Features of popular waterproofing methods

Floor protection from moisture can be performed in various ways. After arranging hydroprotection in most cases, the floor is screed, after which tile, laminate or other covering is laid. There are several ways to carry out protective work:

Hydraulic protection of the bathroom by the pasting method , glass ruberoid, roofing sheet, polyethylene, polypropylene, PVC film) is cut to size of the room. Then the prepared parts are glued to the primed plane with an overlap or butt joint; in the latter case, the seams must be welded or glued. They use polymeric multilayer membranes, which also have thermal insulating properties. Which waterproofing is better for the floor is decided in each case individually.

Obmazochnaya (painting) waterproofing

Obmazochnoy waterproofing wooden floor in a private house is the most affordable and therefore the most common method. Bitumen, plaster mixes, mastics (bitumen-polymer and bitumen-rubber), sealants and polymeric varnishes are used as hydroprotection. The base, cleared of debris and dirt, is moistened, then treated with a primer to ensure better adhesion. Following the manufacturer's instructions, the mixture is prepared.

The material for waterproofing the floor is applied with a brush, roller or spatula; after 4-6 hours stack the second layer; final thickness does not exceed 2-20 mm. After work is completed, the joints are sealed (the joints between the floor and other surfaces and the entrance of the pipes); screed and tile laying can begin in a day.

Completed paint insulation of the bathroom

Coating waterproofing is applied to any surface, it is easy to handle hard-to-reach places. It is considered the fastest method; but over time, cracks may appear on the surface of the bitumen or polymer coating.

Fill-in waterproofing

This method is suitable for protecting the floor of wet rooms. The formwork is mounted on the basis. Bulk materials are added (concrete, hydrophobic powders, perlite sand or ash, asphalt-insol).

Under the action of water, the granular mixture is evenly distributed and acquires the consistency of the gel, becoming an obstacle to the further spread of moisture. The thickness of such a waterproofing can reach up to 50 cm.

Plastering waterproofing

Plastering materials for waterproofing the floor have an important advantage - at 0⁰C they do not lose their properties and do not form cracks . Plastering waterproofing is easy to use and environmentally friendly. The mixtures include cement, gypsum, mineral and polymer additives, which make the elastic layer resistant to strong temperature fluctuations (from -20 ° C to +50 ° C).

Preparing the floor for applying water protection

It might be interesting! In the article on the following link read about waterproofing under the metal.

The surface is treated by applying 2 (less often 3) layers. Layers are applied in directions perpendicular to each other.

Molded floor protection

For casting, solutions and waterproof mastics consisting of a plastic base with additives are used. Polymers, bitumen, resins, liquid rubber, plasticizers are used as additives.

Unusual protection option - 3D poured floor on video:

The material is distributed over the primed concrete base in two ways - in hot or cold, in several stages. Then the surface is dried with hot air (gas burner, IF radiation). For additional reliability, the layer is reinforced with fiberglass or metal mesh. The thickness of the film in finished form is from 5 to 15 cm. alkaline earth metals).Such a composition is able to penetrate deep into the concrete surface (some 50-60 cm), making it waterproof. Ceramic tiles can be laid directly on top of hydroprotection.

Waterproofing of wooden floor, logs (bars for flooring)

Features of waterproofing wooden floor

Wood - natural porous material, easily absorbing moisture. Because of this feature, the unprotected wooden surface inevitably begins to deform, crack and rot.

To protect the wooden floor from harmful effects, a waterproofing technology has been developed for the sub-floor. Ventilation is certainly arranged between the draft and the finished floor. Such design will provide natural air circulation, keeping a comfortable microclimate in the house.

Waterproofing a subfloor in a wooden house is an essential element. For concrete slabs, non-moisture-permeable materials are used (roofing felt, plastic film). For a wooden subfloor, choose a treatment with building compositions (varnishes with polymers or on a bitumen basis). Sometimes, due to the characteristics of the house, the coating is installed on the logs.

What to look for when working

New buildings are characterized by high humidity. Such a microclimate in the house can not only spoil the repair, but also damage the bearing parts of the building. Waterproofing of the house is carried out in the following order: foundation, basement (if any), floors. So you can protect wooden structures from rotting, and metal - from corrosion.

One type of decorative self-leveling floor with protective properties

Due to poor-quality waterproofing of the first floor of the house, doors often suffer. Moisture rises on the wall, permeates the unprotected parts of the wooden box. The structure loses its strength, deforms, loosens and starts to rot.

Oil paint or varnish is not waterproofing. Their lifespan will be limited to 4-5 years, after which they begin to crack and crumble. Also as a waterproofing material can not be used floor tiles - this is a finishing material.

It may be interesting! In the article on the following link read about the membrane for waterproofing the foundation.

Conclusion

By following the rules of waterproofing the floor, you can avoid a large number of problems in the future, both with a losing structure and with the health of loved ones (exacerbations of allergies, rheumatism, respiratory diseases are possible). The method of waterproofing the floor is selected based on the allocated finance and type of premises. In any case, following the technology will make the protection quality and full.