The stone structure as a whole or the finishing of a house with a stone always evokes a feeling of confidence, calmness, harmony with nature. Visually, a stone house is perceived as a reliable shelter from the elements, weather, and external influence. The stone facade of the house characterizes its owner as a solid owner with good taste and high level of material well-being.

Of course, today there is no need to build completely stone houses, to create some medieval castles. Ancient and, at the same time, modern material is today in demand in the design of facades and for additional decoration of individual elements of structures. The range of material on the market is large, so a potential buyer, the developer, it is desirable to navigate in diversity and make the right decision in choosing a stone for the facade of the house.

Pros and cons of stone cladding of facades

Stone cladding of facades of buildings benefits in comparison with any other materials in terms of strength and durability. This is the main argument, regardless of the origin of the material: it is mined in a career or created by human hands. The impact of stone blocks on human health has been studied for centuries of use - it is one of the most environmentally friendly materials.

Advantages of the facade of natural stone

In addition to the effective and elegant appearance of the house, the stone cladding has many practical advantages over other finishing materials:

-

The material that has been formed over the centuries is extremely practical : it is able any natural disasters, a practically unlimited number of freezing and defrosting cycles, strong static and dynamic mechanical loads act.

-

Ecological safety of living in a house with stone facing is unconditional, especially in comparison with modern polymeric building facing materials.

-

The service life of the stone block facade is unlimited. The most short-lived of the rocks, for example, limestone, can serve dozens of generations - signs of their destruction appear only after a millennium.

-

In nature, it is impossible to find two identical stones, which means that the house will have its own individual face and a unique appearance.

Disadvantages

A significant drawback of the material is its weight . These are additional transportation costs, processing difficulties.

An important negative point of the cladding device in a long-built house that is not designed for a stone trimming device may be the lack of a reliable base for facade cladding. This also entails significant costs for strengthening or extending the foundation .

Advantages of artificial stone

An artificial facade stone can be created on the basis of cement, gypsum binders, using various technologies for burning clay or imparting desired properties to polymers. The main goal of such technologies: the creation of a material that looks like a stone, but at a much lower cost. There are many such materials on the market and the manufacturer gives them the necessary properties and qualities for a specific purpose:

-

the necessary weight and optimal dimensions for efficient operation and ease of installation;

-

sufficient parameters of resistance to all types of atmospheric and mechanical effects;

-

stone can be “aged” or emphasized and highlighted the properties of color and texture of the simulated rock;

-

to make installation easier, special form angles, slopes, complex architectural decorative elements;

-

convenience and ease of handling during the construction works.

Even an expert cannot always visually distinguish an artificial stone from a natural one.

Disadvantages

The main disadvantage of the material of artificial origin is considered to be its much shorter service life in comparison with the natural one - it is difficult to compete with nature.

There is a risk of acquiring poor quality material that does not meet the specified quality and safety parameters.

Natural natural facing material

The stone for facing natural natural origin is an excellent finishing material. But it cannot be used for cladding in its natural state: certain processes are required to turn lumps into building material.

Initial processing, properties, pricing

Tile is made by mechanical or manual processing with all the qualities and properties of the original stone block, but much lighter in weight. The complexity of processing depends on the density of the rock, but new technologies allow cutting and converting any stone into an excellent building material.

Tile pricing is made up of the costs of extraction, transportation, and processing. It is more rational to purchase stone from nearby deposits, because the cost of transporting heavy material makes up a large part of its value.

Sawn stone

Naturally processed stone, usually called sawn. It has unique properties for strength, durability, decorativeness, and its specificity is due to the presence of a wide variety of cutting options.

Types of sawn stone tiles are numerous, they can vary in breed, color, shape, processing, size.

On our site you can familiarize yourself with the most popular designs of houses decorated with fiber cement panels from construction companies presented at the exhibition "Low-Rise Country".

5 types of stone for facades

For professionals, the following division by types is accepted:

-

Euro-2 ": tiles with dimensions of 60x30x2 cm;

-

slabs: made of solid blocks;

-

wild stone: irregularly shaped layers with treated corners;

-

plate: consists of pieces;

-

Moscow coat: plate-like material, characterized by torn edges from the main side.

Wild stone: the most popular material for cladding facades

A material created by nature for thousands of years. Wild stone has a variety of options for combinations of shapes and colors. Obtained by splitting large slabs, the cladding material for the facade has a different shape, size, rough surface and torn edges. Its deposits are found everywhere, it is in demand and popular as a stone for the facade of the house, the variety of types and types can satisfy every taste.

It is divided into the following varieties:

-

Plitnyak , or a torn stone, the plushka is uneven, non-edged material in the form of a flat slab with irregularities, is considered the main kind of raw wild stone. The size of the technological stone slab is 40x40 cm, thickness is up to 3 cm, the texture is unique and is not subject to perfect imitation.

-

Fat Man used mainly in laying walls, pillars, columns because of its decorative edge. Stone blocks with a thickness of 6-15 cm are used for retaining walls.

-

Wild Rubble Stone it has arbitrary sizes and shapes, it is used in its raw form for the construction of landscape objects.

On our site you can find contacts of construction companies that offer a house building service from fiber cement panels. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Forms, names, subspecies

The most common species and functional forms of tiles can be considered as paving stones, pebbles, flagstone, breccia, noodles, brick, corner. The names are usually very figurative: for example, a tile, shaped like a noodle, is also divided into subspecies: an arrow, a crust, a strip.

It is not at all necessary for a buyer of a natural stone to know all its varieties and modifications - it is important to understand that any desired shape and color can be found on the market.

Technology of installation of a stone facade

The basic rules for laying do not depend on the type of stone for the facade, its shape or rock. The technological process can be divided into two stages: surface preparation and lining.

Preparation

Preparation of the working surface for lining is obligatory, it includes:

-

cleaning the surface under the lining from dust and dirt;

-

degreasing and, if necessary, removing the old coating;

-

repairing chips, cracks, gouges.

A galvanized metal mesh is attached to the cleaned surface for tight bonding with the facing layer.

Grid packing on rough, durable surfaces is not always necessary, there are enough notches in the facing area. But its use is desirable for better adhesion of the cladding and base in all variants and for all types of stone.

The mounting options for the grid depend on the surface material, but, as a rule, the grid is fixed with dowels of sufficient length to fix it firmly.

Installation of the stone: the main points

You can identify the main technological operations of facing the facade :

-

Laying the material with the sawn surface is performed on cement-sand mortar, the joints are filled with special mastic or the same mortar with grout or jointing.

-

If the thickness of the stone block is no more than a centimeter and the area is no more than 0.4 m², additional fasteners are not needed.

-

Small gaps are necessary between the stones in the masonry.

-

The base is made of stone blocks of a darker color.

-

The most careful control is necessary when removing corners, facing slopes and eaves.

-

The completed type of work is attached with additional measures to preserve the decorative and operational qualities of the facade. One of the primary measures is considered to be hydrofibization of the facade from the appearance of moss, mold and vegetation.

How is the facing of natural stone

done Before the beginning of the facing works, the working solution is prepared, then there are the following work steps :

-

The zero or starting level is determined.

-

Corners of facing are set in, that is, the tile is first fixed on the corners of the wall.

-

Level break or corner joint with a thread for the bottom of the initial row.

-

A slurry layer is applied to the stone and to the wall surface.

-

The stone is pressed, the excess mixture is removed.

-

Constant monitoring of the vertical level is carried out.

-

Eaves and window slopes are faced after facing the walls. After facing one wall, the whole process is repeated on an adjacent surface with transfer of the starting mark to it.

How the installation of a natural stone is performed, see the video:

It might be interesting! In the article on the following link, read about the front panels under the brick.

Installation of artificial stone

Installation of artificial stone can be carried out with glue directly on the base or by hanging on the system of a ventilated facade. In practice, the mounted method is applied only on the lining of the foundation, and the walls are lined with gluing.

Surface preparation is similar to preparation for natural stone.

For the surface lining with artificial stone, see the following video:

Brief characteristics of the main types of stone

Each of these materials has it’s good and has a lot of merit, and it’s important for consumers to know them in order to choose the best option for finishing with a stone on the facade of a house.

-

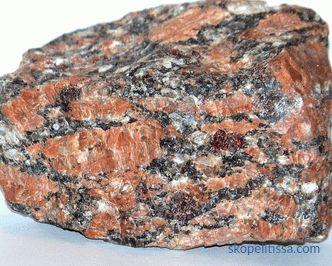

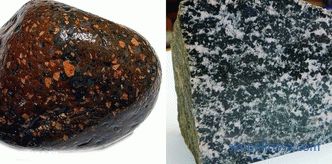

Granite . Material magmatic origin, the most durable, but also the most difficult. A large proportion creates difficulties in handling, transportation, installation, which affects the price - has the highest cost.

-

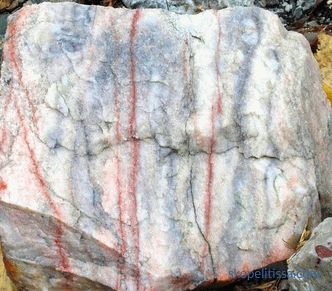

Marble . Beautiful, dense, accessible in processing, but difficult in operation. Possible loss of appearance and the formation of spots in certain adverse conditions.

-

Limestone . Material of organic origin with a number of positive parameters: the mass is small; has heat insulation properties; safe from the point of view of ecology; has antibacterial properties; well treatable. The facades require treatment with water-repellent compositions. Available at a price.

-

Sandstone . Durable, non-polishable, rough to the touch, a popular finishing material. It has colors: yellow, beige, dark brown. It has a relatively inexpensive price.

It might be interesting! In the article on the following link read about the wet facade.

-

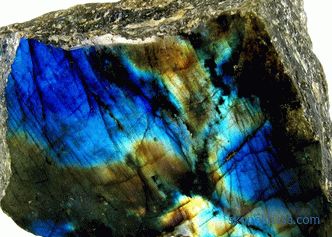

Labradorite . Reliable, not afraid of low temperatures, available for polishing material with blue, red, yellow patterns.

-

Syenite . Light, porous, durable, easy to polish. The disadvantage is rapid weathering.

-

Porphyry . Durable, polished, not fading breed of dark red color with identical chemical properties to the grant.

-

Dolomite . Beautiful material, but with a small variety of colors. Not afraid of changes in temperature, fire, frost. The price is high.

Specialist services

Companies specializing in the processing of natural stone , can offer a lot of unexpected (from the layman’s point of view) services and additional processing and refinement operations:

-

cutting of the stone preparation with a straight and curved cut;

-

production of original and exclusive products of complex shape, panels, mosaics;

-

polished ends with various types of chamfer;

-

surface aging using acids and diamond brushes;

-

in Cutting holes and cutting cannels with a mill;

-

repolishing and polishing the second side, rounding corners, reinforcement.

For the selection of artificial stone, see the video:

Prices for facade cladding in Moscow

Pricing for cladding facades by construction organizations should be made on the basis of ENiR norms (Uniform Standards and Rates), multiplied by the coefficient in effect at the time of the work. In reality, the prices of construction work in different organizations can vary considerably. The price for work can be influenced by the following factors:

-

volume, time and place of work;

-

condition of the walls under the cladding and degree of difficulty of the preparatory work ;

-

type, type and even the price of the finishing material.

If we talk about the average current price for the execution of facade works, we can dwell on the following amounts for 1 square. m cladding:

-

working with natural stone on finishing facades and socles will cost the customer 2000 rubles \ m²;

-

the same works, but with artificial stone blocks - 1400 rub \ m².

Do not forget about the additional work. For example, the waterproofing of the facade stone surface will cost about 75 rubles / m².

Stone can even be finished with wooden houses - an example in the video:

It can be interesting! In the article next link read about facade panels under the stone.

Conclusion

Facing the facade of the house with a stone is a rather laborious and complex construction process. In order for the money spent on excellent, but very expensive material, not to be in vain, the lining work must be carried out by professionals. A selection of material is still better to do to the customer (together with the performer), because this choice is forever.