Today we will talk about building material, which was recently considered to be purely wall. Currently, manufacturers offer its variety, which covers the roofs of buildings and structures. This is a roof of sandwich panels. In the article we will discuss issues relating to the structure and composition of the material, its classification, as well as the technology of mounting on the roof truss system, taking into account some nuances of construction operations. Understand the information received, will be, as they say, on the same wavelength with the masters who were entrusted to cover the roof with sandwich panels.

What is a sandwich panel

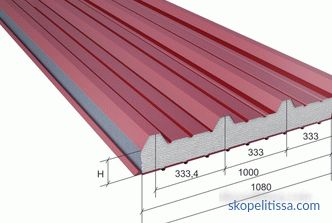

This is a three-layer material formed by metal sheets between which the heater is laid. Either polystyrene foam, polyurethane foam or basalt wool is used here as thermal insulation. The first two options are preferable due to their higher technical and operational characteristics.

A galvanized steel sheet coated on top with either paint or polymer is used as metal plating. This primarily increases the protective qualities of the steel sheet, prolonging its difficult operation on the roof. Secondly, this is a huge variety of colors, which allows architects and designers to solve some design problems.

At the same time, all the layers between themselves are glued together with a special compound - a two-component polyurethane adhesive, which gives the three-layer construction special strength. It must be added that steel sheets are not necessarily a flat surface. Today, manufacturers mainly offer roofing sandwich panels for the roof with a profiled shape in the form of sheeting. That is, with a trapezoidal shape or wavy.

Advantages of sandwich panels

The first advantage in the list of positive characteristics of this building material - a complete set of roof in terms of insulation and waterproofing. That is, having mounted the panels on the roof, you immediately solve the whole problem. With insulation it is understandable, but waterproofing solves the bottom sheet of galvanized sheet.

And other advantages :

-

long-term operation with proper installation;

-

a small specific weight , and this reduction in loads on the truss system;

-

calmly withstands quite serious loads ;

-

minimum deformation ;

-

high sound and heat insulation characteristics;

-

high fire resistance ;

-

increased aesthetic qualities;

-

speed roof assemblies;

-

material is practically not subject to climatic features Gion.

In this list, we add that the minimum roof slope of the sandwich panels is 5 0 . But with one condition that the panels will be selected taking into account the length of the house run. With a slope of more than 10 0 it is allowed to mount different lengths of the panel, strictly joining them using a special technology.

And one more positive side. Sandwich panels are universal material, so today they are used to cover roofs, regardless of the purpose of the building itself. Even for residential buildings.

On our site you can find contacts of construction companies that offer design and performance services. roofing, finishing and insulation of houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Specifications and dimensions

To begin with, this roofing material is produced by many manufacturers according to technical conditions. Although there is a GOST number 32603-2012. True, the standard is intended for panels with mineral wool insulation.

So this document says that roofing sandwich panels, denoted by the letter “K”, should be produced with exact dimensions :

-

thickness 50-300 mm;

-

width is strictly 1000 mm;

-

Length 2000 to 14000 mm.

Many manufacturers strictly adhere to these requirements. But they offer longer panels if you place an order for them. In this case, instead of mineral wool, they use more high-quality insulants in terms of both strength and reduced thermal conductivity. This is polystyrene or polyurethane.

As for metal sheets, then, as mentioned above, this is a flat surface, trapezoidal, wavy and with a reel. The last is the grooves either at the top or at the bottom of the wave, which serve as ribs. Rolling panels are considered more durable roofing elements. By the way, the roll is done both on the bottom steel sheet and on the top.

On our site you can familiarize yourself with the most popular designs of houses for which sandwich panels were used and ventilated facade - from construction companies represented at the exhibition "Low-Rise Country" houses.

And a few words about characteristics :

-

thermal conductivity depends on the type of thermal insulation material used: mineral wool 0.034-0.044 W / m K (depending on density), polystyrene foam - 0.03-0.04 W / m K, polyurethane foam - 0.019-0.025 W / m K;

-

density - 40-50 kg / m 2 ;

-

service life is 50 years.

Installation technology

To begin with, the roof of the sandwich panels is primarily a quick and fairly simple installation. But, as in all construction operations, careful preparation is required.

Preparatory stage

It includes:

-

checking the accuracy of the plane of the roof run, no differences;

-

strict perpendicularity between the uprights and bolts;

-

check the angle of inclination ramps;

-

If additional waterproofing is required, then it is also carried out.

Features of installation

As already mentioned, installation is a simple process. But it has a lot of nuances on which the quality of the final result depends.

To begin with, a metal truss system is laid under the sandwich panels for the roof. These are either steel standard profiles or galvanized sheet load-bearing elements that mimic standard profiles. If the first option is used, then the profiles will have to make holes in advance for fasteners in advance. If the second option is used, the small thickness of galvanized elements are easily drilled by roofing screws for metal, which are used to fix the roofing deck.

It might be interesting! In the article next read the link about the house of the sandwich panels.

And one more thing related to the processing of the material. Often the panel has to be cut in length or width. The grinder can not be used. The speed of rotation of the cutting disc of the power tool is enormous. On the surface being cut, a zone of elevated temperature is formed, which burns the zinc and polymer layer, exposing the metal. It is in the places of cut that the panels begin to corrode, which is why their life is reduced.

So, algorithm of installation operations :

-

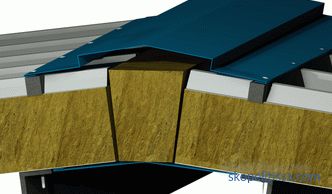

It is necessary to prevent contact of sandwich panels with supporting structures. Therefore, the latter, or rather, their contact surfaces are closed with self-adhesive sealing tape.

-

With a crane the panels raise to the roof where they are laid, starting from either side of the roof structure.

-

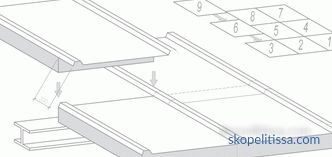

Neighboring panels are connected with a locking joint , which ensures complete tightness of the joint. Some manufacturers recommend additional use for sealing silicone sealant, which is applied to the surface of the lock.

-

All panels are attached to the supports with special self-tapping screws , which have two threads: the lower one for fastening to the support, the upper one for holding the upper steel sheet. Self-tapping screws are completed with gaskets made of neoprene rubber, which under the influence of natural loads throughout its operation does not change its qualities and properties.

It is very important to properly tighten the self-tapping screws. First, they are screwed into the upper wave of sandwich panels. Secondly, it is impossible to over-tighten them, this will squeeze the gasket, which means it will slightly open the mounting hole for moisture penetration. By the way, it is impossible to fail too for the same reason. Thirdly, it is necessary to twist the fasteners exactly perpendicular to the roofing plane.

Since the lock joint is almost an overlap, the adjacent abutting panels need to be fastened together on top galvanized steel sheets. For this, short metal screws are used.

Watch the video, which shows how to properly cover the roof with sandwich panels:

It can be interesting! In the article on the following link, read about the sandwich panels wall.

Installation with transverse joints

If the length of the slope is large enough, and one parameter does not close this parameter, then use the laying of material with transverse joints. It uses a very interesting technology, which is based on the process of forming the overlap of two adjacent panels.This is done like this:

-

the lower steel sheet is cut by the length of the overlap of the panel, which will fit as the top element;

-

the same distance is cut off and the heater ;

-

only top sheet ;

-

remains trimmed thus panel is placed on the next , closing the part of the bottom panel with the remaining steel protrusion;

-

self-tapping screws with an obligatory greasing of the plane of the overlap with sealant.

Note that if the slope of the slope is 5-10 0 , then the overlap value must be within 300 mm, if the angle is greater than 10 0 , the overlap length is 200 mm. Look at the photo below, where it is shown how the sandwich panels are laid according to this technology, and in what order they should be mounted on the roof.

In principle, this means that the roof sandwich is ready. It remains only to install additional elements. This is the first horse. Insulating material is laid between the upper edges of the laid panels, and the top is covered with a metal element painted in the color of sandwich panels. If there is a junction of the roof to the protruding wall, then this joint is closed with a so-called splat. This is an angular type profile, one shelf of which is attached to a vertical surface, the other to the surface of the panel, thus closing the joint.

About the types and characteristics of sandwich panels the following video:

It can be interesting! In the article on the following link read about the project and the finishing of the soaring frame-modular house.

Conclusion on the topic

Today, sandwich panels for roofing are one of the most sought-after materials of the new generation, especially in industrial construction. The ease of installation does not mean that illiterate and inexperienced masters can carry out this process. To spoil the panel will not be easy. Therefore it is very important to strictly follow the instructions provided by the manufacturers.