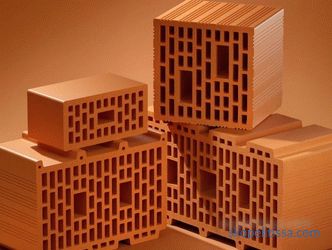

Today construction has advanced, using new technologies and modern materials. One of these is a ceramic block - a high-tech material made by firing clay. It is an excellent alternative to bricks, showing unique properties and high quality. The ceramic block several times exceeds the brick in strength, service life, and also has good thermal insulation properties. Next, we will talk about what constitutes a ceramic block, what are the pros and cons, what are the features of its use in construction.

What is a ceramic block?

Ceramics are products obtained by firing clay. Such processing of clay raw materials makes it possible to manufacture not only dishes, but also such building material as bricks or ceramic blocks.

The production technology of keramoblocks is similar to the manufacture of bricks, but it requires the latest equipment. The main production material, as already mentioned, is clay. In order to reduce the density and improve the quality of ceramic blocks, special additives are additionally used - porizers, which can be processed sawdust, rice husks, peat, straw.

Porizers in the composition of ceramics may account for up to 50% of the total volume of raw materials prepared for production. Depending on the volume of such additives, the heat-engineering properties increase, however, the strength indicators of ceramic blocks decrease.

Ceramoblocks of various sizes.

The production process of the material

The entire production process in the manufacture of ceramic blocks consists of several stages:

- Fusible clay is mixed with porous additives and get a mixture called a mixture. Such a mixture is processed on special clay-grinding devices, as a result of which the porizers in the charge are crushed, and the entire clay mixture becomes more homogeneous. Without modern equipment, crushing the mixture to the desired consistency is almost impossible.

- The next step is the formation of blanks from a mixture of clay , for this, also, special equipment is used - a vacuum extruder. At this stage of the process, the charge enters the vacuum chamber of the press, where all the air is removed. At the exit, the raw material takes the form of a bar having a certain surface with voids.

- Such a blank is cut into blocks , which are stacked on the shelves and fed to the dryer, where moisture gradually comes out of them. This process can last from 2 to 3 days, with a change in temperature from 30 to 110 C °.

- After drying, the ceramic blocks enter the tunnel furnace , where the final stage, firing, takes place. The procedure lasts about 45 hours at a temperature up to 1000 ° C. At this point, the clay is baked, turning into ceramics, and porous additives burn out, leaving pores in the block, which contribute to a decrease in its weight and thermal conductivity.

- The fired products are placed in wooden pallets and packed in film.

Sometimes the finished blocks are polished, it is necessary when using such walling technology as seamless masonry. It also happens that the voids are packed with basalt fiber or other material, this allows you to avoid the flow of adhesive in them during construction.

Important! At the slightest violation of the production technology, the strength characteristics of ceramic blocks are reduced, therefore, it is necessary to acquire material from reliable manufacturers and only with all necessary quality certificates.

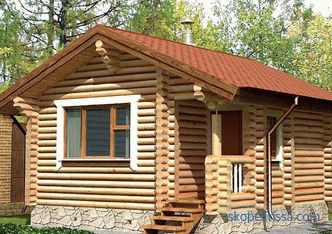

Keramoblock house without exterior finish

Technical characteristics

The main feature of ceramic blocks is hollow porous structure , which is obtained as a result of burning out of additives during roasting. Technical specifications are directly dependent on the size of the blocks, as well as on the composition of the raw materials used for their manufacture. It is these indicators that influence the design features of the building for which the ceramic block was used. The dimensions of a unit of material may be different, and the properties vary accordingly depending on this indicator.

Main characteristics of ceramic blocks:

| Size (mm) | Weight (kg) | Mark strength | Mark cold resistance | Indicator moisture absorption (%) |

| 120/500/219 | 11.5 | M100-150 | F50 | 14 |

| 250/380/219 | 17 | M100-150 | F50 | 14 |

| 380/250/219 | 17 | M100 | F50 | 14 |

| 510/250/219 | 22 | M100 | F50 | 20 |

| 250/120/140 | 3.9 | М125-150 | F50 | 14 |

The original ceramic block house .

Advantages and disadvantages

Building houses from ceramic blocks is popular today due to the following advantages :

- Good energy saving abilities give possibility of laying in one layer, which saves construction time.

- Sound-proofing characteristics allow using the material both for load-bearing walls and for partitions without additional sound insulation.

- There is no need to lay a reinforced foundation, since the density of this material is similar to wood, and the weight is much less than that of a brick.

- Vapor permeability promotes self-regulation of the humidity level in a building.

- The natural components of the composition make ceramoblocks ecologically safe.

- Calcined clay is a non-combustible material, so the blocks have a low fire hazard class.

- Exact observance of the production technology and high-quality firing guarantee a long service life of both the ceramic blocks and the structures erected from this material.

Like any building material, blocks of baked clay have disadvantages :

- Fragility. The porous structure makes the blocks fragile, so care must be taken when transporting.

- High moisture absorbency. Keramobloki should be stored in a dry place, excluding contact with water.

The indicated pros and cons of ceramic blocks will help determine the choice of material for the construction of a country house.

Keramoblock house under construction.

Stages of building a house of ceramic blocks

Having decided to build a house on a suburban site, there is always the question of choosing a material. Recently, brick was considered one of the best materials, but now it has been replaced by a modern high-tech ceramic block.

Construction of ceramic blocks is divided into several stages:

- design of the house;

- earthworks;

- foundation installation;

- installation of walls;

- erection of floors;

- roofing works;

- finishing.

Construction of the foundation

After preparing the site, carrying out the preparatory work on it and developing the plan, you can begin to build a house from ceramic blocks or a cottage.

A ceramic block house does not require a strong reinforced foundation, since the material has a low weight.

After the foundation is ready, it is necessary to install waterproofing, since porous blocks absorb water well. Its role can be played by a special moisture-proof material based on bitumen (roofing felt), produced in rolls. Joints should be overlapped, not less than 10 cm.

Ready-made house of ceramic blocks.

Laying walls and floors

Compliance with the technology of building walls for a house of porous ceramic blocks gives a guarantee of obtaining an excellent result, having a uniform texture, the absence of cold bridges, and deformations that affect the finished comfort housing.

Preparation for laying walls includes the following nuances:

- It is imperative to perform waterproofing at the junction line of the wall and foundation.

- The adhesive solution must be of such a consistency, in order to avoid its penetration into the cavities of the blocks.

- Laying with the help of heat-saving composition should occur at air temperature not lower than 5 ° C.

Ceramoblocks, in the process of building walls, have their own styling features :

- laying starts from the corners;

- applying the solution on vertical block surface is not required;

- when using cement mortar, blocks need to be wetted with water;

- corner rows you need to build at least three before you start laying walls;

- exterior walls erected simultaneously with bearing internal partitions.

Cottage of ceramic blocks with brick trim.

Wall cladding

To protect the walls of a ceramic block building from environmental influences, additional external decoration of the building will be required. Houses made of ceramic blocks make it possible to realize any idea in the design of the facade:

- Classic brick finish. The use of facing bricks has several advantages and many years of practice. Ligation of this material with the main wall has no difficulties, the lining process does not require much time and cost.

- Plaster is ordinary. This is the most economical option for finishing the facade, with a wide range of mixtures that allow you to give an original look to the building. The disadvantage is the short lifespan and the need to repeat the plastering procedure after about 5 years.

- Insulating plaster. Combines two properties - decorative and functional. Thermal insulation is enhanced by the installation of special plates on which plaster is applied.

Cost of ceramic blocks

Ceramic blocks are sold individually. Therefore, before buying you need to calculate the right amount, focusing on the plan of the house.

The average cost of a ceramic block is about 110 rubles per piece. Approximately 40 pieces per cubic meter.

Summing up, it is worth noting that the ceramic block has positive reviews on quality, the whole hitch lies in a fairly high price. But taking into account all its properties, this material wins and therefore gains popularity in construction.

Rate this article, we tried for you