The reasons that shorten the life of the foundation, and, therefore, of a residential building, include precipitation, melt and groundwater. Poor (or damaged) internal waterproofing of the basement is not able to resist the penetration of moisture. Corrosion and destruction of reinforcement will be the most terrible consequence; further will be the destruction of the foundation, which assumes the entire load. In disrepair may be the whole house.

This foundation must be waterproofed urgently

Why do we need an internal waterproofing

To waterproofing the basement could completely fulfill the responsible mission of protection, it is necessary to choose the right method, carefully follow the technology and use suitable materials.

The cellar's waterproofing is necessary if:

-

the groundwater level in the area is high and groundwater is flooded (seasonal);

-

due to mistakes made during construction condensation forms on the walls of the basement;

-

insulation is damaged, water penetrates into the basement;

-

it was decided to restructure the basement under the dwelling (rest room, workshop, gym).

Why is it wet in the basement

Leakage or increased humidity in the basement is capable of causing material damage to the owner in the form of a crop dead from mold and fungus. Also likely becomes a threat to human health and the condition of the house. To eliminate the problem, it is necessary to determine the causes. They can be:

-

changes in GW or climate (seasonal);

-

foundation defects (poor-quality casting or seams);

-

waterproofing defects on the outer surface of the walls;

-

absence or poor operation of exhaust ventilation (condensation).

Water can seep through any cracks

Types of waterproofing

Internal ceiling and floor waterproofing (horizontal). The laying of the floor waterproofing is carried out in any case during its installation, since it is impossible to predict a change in the GWV in the future. Leaks on the ceiling can occur due to heavy rains, so they also prefer to isolate it.

Vertical waterproofing of the basement from the inside. Required if there is no drainage system or groundwater level reaches walls. In such conditions, work is combined with a horizontal insulation device to eliminate the appearance of moisture inside the room.

What materials are used for waterproofing

The basement is waterproofed from the groundwater from the inside by using different types of materials that form two large groups:

-

build-up;

-

painting or coating.

There are several methods for waterproofing, taking into account the peculiarities of the construction, the surrounding soil and the materials used.

The build-up insulation will have to be strongly heated

Piercing insulation

Piercing waterproofing of the basement from groundwater is performed using special materials that can penetrate into the structure of concrete or brick. The composition of penetrating elements include cement-based polymer additives. Upon contact with water, they form a mass that fills the smallest pores of the walls.

A representative of this group of waterproofing materials is Penetron, a penetrating material of primary waterproofing of concrete structures with an unlimited service life. The mixture is applied to a wet concrete surface, penetrates the pores of the concrete and forms crystalline structures in them. Such crystals prevent the penetration of water, increasing the strength and corrosion resistance of the surface.

Clearly about penetrating insulation "Penetron" on video:

Waterproofing on cement base (cement mixtures)

Used for walls in a complex with penetrating waterproofing, has maximum adhesion (adhesion) among all materials. Coating cement mixtures are produced in the form of hard (dry mixes) and flexible (dry mix and polymer emulsion) materials.

Liquid insulation (coating)

Used as a basement floor waterproofing, suitable for exterior insulation works. It is made in the form of mastic.

It cannot be used on walls - finishing materials do not stick to it, and fixing elements (when plastering a wall with plasterboard) will violate the integrity of the protection.

Rolled insulation

Refers to surface varieties, uses bitumen impregnated materials. Creates a protective layer on the floor, but does not protect the foundation. It is used together with a coating material, it is laid using a gas torch. This method is not recommended for processing walls, as it will make the interior decoration impossible.

Rolled materials are overlapped.

The rolled materials include ruberoid, waterproofing, Aquaizol ".

Membrane waterproofing

Waterproofing the basement from the inside from groundwater can be done in two ways, depending on the groundwater level:

-

Polymer film. It is a roll material with a thickness of 0.2 mm, which is used for sealing, if the basement floor is located above the groundwater.

-

Profiled. This is a corrugated sheet (studded or bumpy) of laminated polyethylene, which is used if the groundwater level is above ground level. The material is mounted on the wall; It is designed for long-term containment of water (during the entire period of operation of the house).

Roll of membrane waterproofing

Injection protection against moisture (a kind of penetrating)

This method allows you to secure not only the inner surface of the walls and the floor, but also the supporting structure. It is applicable in the presence of active water leaks or defective areas (voids in concrete).

Injection insulation provides high adhesion (bonding) of the applied layer to the wall structure. The method is quite expensive, but it allows you to provide reliable protection and save on repairs in the future.

Injectors are required for work. Cement or polyurethane compounds are used as mixtures, which expand and push water out of the thickness of the structure. Protection by injection allows you to conduct high-quality waterproofing basement. It is carried out in several stages:

-

holes are drilled in concrete; they are staggered;

-

an injector is placed in each hole;

-

the pump is connected in turn to each injector;

-

successively under pressure a mixture is poured into the holes.

Clearly about the use of injection isolation on video:

Liquid glass

The technology is universal and suitable for concrete, metal and wooden structures. Raw materials have several advantages:

-

penetrates deeply, quickly solidifies and completely fills the voids of the walls, crystallizes outside and requires a small expenditure of time and material;

-

reduces moisture absorption;

-

provides chemical and biological protection for walls.

A few more facts about liquid glass in the video:

Liquid glass is distinguished by chemical composition. It is sodium (sodium silicate) and potassium (ceramic liquid insulation). The main requirement is strict observance of proportions, otherwise instead of strength, you can get brittleness.

Waterproofing according to the method of action

Depending on the external conditions and the condition of the soil, there are three types of basement waterproofing:

-

Anti-pressure. Applicable with the pressure of aquifers no more than 10 meters (in the private construction of underground structures with a height of 3 floors) and the absence of a drainage system. Roll-type seals are used that can hold water pressure. The material is applied to the surface of the structure from the outside and pressed against it by water pressure.

-

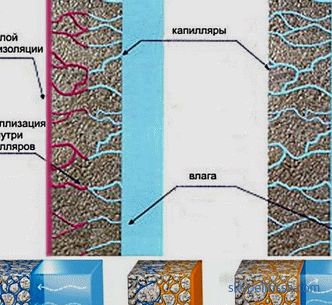

Anticapillary. It protects against high humidity and is optimally implemented by means of penetrating waterproofing.

The principle of the anti-capillary waterproofing

-

Free-flow based on bitumen compositions. Able to protect the basement from temporary flooding (seasonal floods and precipitation).

Stages of waterproofing

How to make an internal waterproofing of the basement with your own hands (work sequence):

-

Clean the internal surfaces thoroughly subject to waterproofing treatment; pump out the water.

-

Completely dry the room.

-

Clean the walls of old materials and dirt.

-

Clear, widen cracks and fill cracks with mortar.

-

After drying of the cracks, prime all surfaces (two times in problem areas); this will provide better adhesion (bonding) of the insulation material.

Applying a primer

-

Seal the joints in the areas of adhesion of the floor and walls with glue for tiles.

-

Waterproofing of walls. Isolation of walls, joints and corners of the room is carried out, they are uniformly soaked with the selected mixture. After drying the second layer is applied.

-

Waterproofing the floor. The floor is covered with bitumen mastic and covered with roll-up waterproofing, which should go on the walls for 20-30 cm. A concrete screed reinforced with reinforcement or metal mesh is poured over the top.After hardening, bitumen emulsion and penetrating waterproofing are applied to it.

-

Cement insulation is applied to the walls, in two thin layers with drying.

The entire process on the video is visually:

During operation, you should consider ventilation of the basement ( Do not forget to make the floodgates in the ceiling) and the processing of the stairs. Waterproofing carried out in this way will protect the room from moisture penetration.

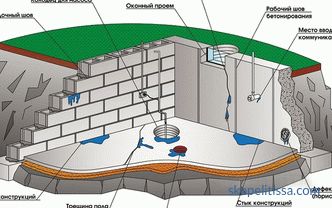

Which areas need to be treated first

Waterproofing a cellar or a basement is a responsible construction process. When performing it, it is necessary to pay close attention:

-

to work joints, joints of ceilings, walls and floors, room corners;

-

to damaged areas (cracks and faults formed after shrinkage);

-

to the areas of supply of engineering communications.

These places should be treated very carefully

What errors are allowed for internal insulation

-

Unprepared premises. It is better to carry out these works in the summer period with a minimum amount of rain when the room is rapidly ventilated and dry. Clean up accumulated water thoroughly, clean and degrease the floor and wall surfaces.

-

Wrong choice of waterproofing products.

-

Incomplete waterproofing of vulnerable areas. Joints, wall bases and corners are not fully protected.

How much will waterproofing services cost?

Many companies offer to insulate basements with a guarantee. It offers customers both competitive fixed rates and attractive special offers.

Many factors affect the cost - the exact amount will be known only after inspecting the place of upcoming work

The total amount is influenced by the following factors:

-

area of the room and the nature of leaks;

-

waterproofing method, determined by external conditions;

-

cost of materials and deadlines set;

-

associated hydro protective measures.

The budget, often used methods include coating insulation. When injecting or penetrating waterproofing, the cost of work will increase, but the basement will be much more securely protected.

Average prices for certain types of work, per 1 m²:

-

coating waterproofing - 400-470 rubles. ;

-

floor waterproofing (mastic + roofing material) - from 300 rubles. ;

-

pool waterproofing (integrated) - from 1000 rubles. ;

-

coating waterproofing (penetrating) - 540-580 rubles. ;

-

coating waterproofing (membrane) - 750-900 rubles. ;

-

injection waterproofing (cracks, seams, cable glands, joints) - 3900-4500 rubles. ;

-

staggered injection - 15200-15700 rub.

For some types of work, besides knowledge, you also need special equipment

The cost of the work, in addition to the cost of materials, may include dismantling the old coating, cleaning and dedusting the surface, making cement screed, priming the surface and other works as agreed with the customer. The exact list of necessary works will be determined by a qualified specialist individually.

Every owner of a private house, garage or cottage building equipped with a cellar deals with the need to waterproof the walls of the basement from the inside. Materials for the protection of structures are different in purpose, features and benefits. Competently chosen treatment of the basement room will protect against dampness, protect from mold and fungus. In the waterproofing structure is valuable not only a dry microclimate, bringing health to the inhabitants. An important effect will be the preservation of the bearing capacity of the foundation and, consequently, the durability of the building.