The construction of low-rise foam concrete houses is popular for two reasons - low cost and high thermal insulation properties of the material. Another advantage - low weight and the ability to save on the arrangement of the base. But in this case too, the foundation for a foam block house should be durable and reliable, and the choice of the type depends not only on the load on it, but also on the characteristics of the soil.

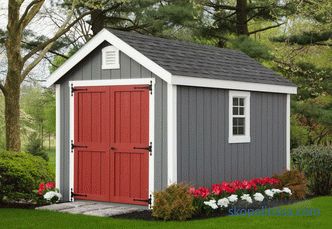

Tape or pile-grillage foundations are most commonly used

Features of foam concrete as a building material and types of foundations

Foam concrete blocks are divided into three categories:

-

heat insulation - density up to 500 kg / m 3 ;

-

structural heat insulation - density of 600-1000 kg / m 3 ;

-

constructional - density of 1100-1200 kg / m 3 .

For the construction of self-supporting walls use construction-heat-insulating blocks, and the most popular brand is D600.

If you make an analogy on the density and load on the base, then the closest to the foam block is softwood, which is used in modern wooden construction in the form of a bar or a rounded log. For comparison, the density of pine and larch in the air-dry condition (with a proper humidity of 20%) is about 600 kg / m 3 . And such it happens after the end of the drying process - wood of natural moisture is 15-20% heavier.

On the basis of this feature, it can be concluded that for the same soils, the foundation for a foam concrete block house is chosen exactly the same as for a log house or bar - tape, slab or pile.

Depending on the type of soil, the type of pile foundation is selected

But unlike logs or lumber, foam concrete blocks are classified as building blocks materials. And vertical seams filled with masonry mortar do not create stable bonds with neighboring blocks, which, when moving or sinking of part of the base, leads to the formation of cracks. Therefore, the pile foundation of the pile foundation should be as rigid as possible, and an I-beam or channel most of all meets this condition.

Selection of the type of foundation

The type of foundation is chosen based on the bearing features of the soil, economic and practical feasibility, and the time allotted for the construction of the house.

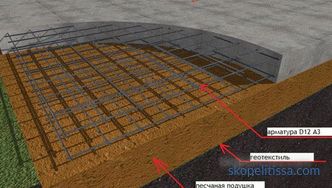

The slab foundation

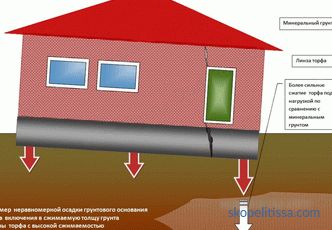

The slab foundation for a light house is made of foam blocks only as a last resort - if the nature of the ground does not allow another option. Fine and silty sands, plastic loams, peatlands get here. And this is not the only condition, the second reason is the deep location of solid, so-called "continental" soil, to which it is difficult to "get" the pile. The slab foundation is also used for wet soil with high groundwater levels.

The slab foundation for the house

Technically, the slab redistributes the load from the walls to a wider "spot", and it floats together with a weak and unstable upper layer. Among all the shallow foundations, this type is the most reliable, but also the most costly in terms of materials and labor intensity of production.

On our site you can find contacts of construction companies that offer the service of designing houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Tape foundations

Tape deepened foundations are set up for a house of foam concrete blocks in cases where the project includes a basement or a technical floor for autonomous life support equipment. In terms of material consumption and production time, it is not inferior to the slab foundation, but the high costs justify themselves by freeing up the usable area at the upper levels of the house.

The ribbon shallow foundation is not less practical than the previous version, but it requires less expenses, including the holding of a zero cycle. The high base allows you to arrange your technical level, and you can lay it out of the building blocks. And as an option, a combined foundation is often used - a monolithic tape or a prefabricated base made of FBS for the underground part and a basement made of building blocks.

Combined strip foundation - with a brick base

The ribbon under-embedded foundation is a type of the previous species. It is laid on rocky and coarse soils. Technically, this is a base, cast from reinforced concrete or assembled from building blocks on a prepared site.

The plinth or fully shallow foundation can be made of foam concrete blocks of the brand D1100-D1200. In compliance with the manufacturing technology, the compressive strength of such a unit is at the level of B10 and B12. 5, respectively, and this figure is the same as for concrete grade M150.And this brand is allowed to be used as a structural (bearing) material in low-rise construction, including for the foundations of lightweight buildings, which include single-story houses made of cellular concrete.

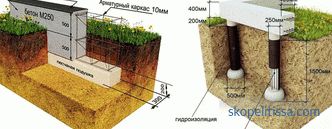

Note! Despite good water absorption and frost resistance, foam concrete has the disadvantage of being able to accumulate "diffusion" moisture. That is, with constant contact with water and poor weathering conditions of excess moisture, the foam concrete construction is moistened and loses its bearing properties. Therefore, the foundation of foam blocks should have a reliable waterproofing, and around the base it is necessary to equip an effective drainage system.

Combined waterproofing of the foundation - coating and roll

It might be interesting! In the article at the following link read about the repair of the foundation of the country house.

A separate type of this foundation is a tape-pile foundation for a foam block house. Its peculiarity is that both the tape and the piles are made of concrete, but the total material costs are much less than in the case of pouring the classic "tape".

Pile foundation

The best option for lightweight and prefabricated houses from foam concrete blocks without a basement and a basement is a pile foundation. It is suitable for most types of soil, copes with loads from low-rise light buildings, does not require large capital investments and labor costs.

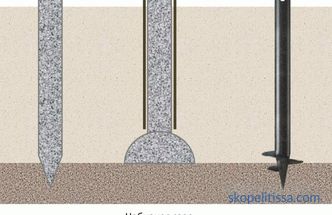

In total there are three types of pile foundations:

-

bored;

-

brown injection;

-

screw.

The first type is often used in industrial and civil construction, and not only in its pure form, but also as part of the combined foundations. With the help of a copra, several dozen reinforced concrete pillars are driven into the ground, which form a pile field. In low-rise construction, such a foundation is rarely used.

Pile field of bored base

The second type has different versions, although the manufacturing technology is reduced to drilling a well and pouring concrete into it mixtures:

-

In dense soils, no formwork is installed, and the pile is reinforced with a bookmark of vertical reinforcement, a “three-dimensional” prepared armored belt or steel profile.

-

In weak soils, so that the walls of the well do not crumble, they can use casing pipes, which, as the concrete is injected, lift up, and the armor belt is laid after the mixture is poured.

-

At the household level, for light structures in weak soils, such a foundation is made using asbestos-cement pipes, which serve as fixed formwork.

-

Use "disposable" drill columns that remain in the well and provide reinforcement to the concrete. This option can be called the prototype of a screw pile.

The drilling injection pile foundation is widely used for country construction on problem soils. Also, this technology has been used to strengthen the foundation of already standing houses in several cases:

-

when the bearing properties of the soil deteriorated due to geological changes (most often by raising the groundwater level);

-

when adding another floor;

-

when correcting the roll of the structure.

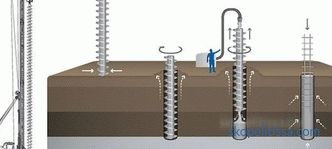

Drilling piles - mounting technology

The disadvantage of this option as a foundation for foam blocks is a long concrete maturation cycle .

A screw pile foundation can be called ideal for a low-rise building. At its arrangement large-scale works on concreting and reinforcing are not needed. And do not wait 4 weeks until the concrete is ripe to design strength, to proceed with the construction of walls. In appearance, the pile is a disposable drilling column with one or two turns of wide blades.

A single-turn pile can withstand loads up to 20 tons, with two turns up to 50 tons. Depending on the nature of the soil and the weight of the structure, the type of pile, length, diameter of the blades and their number is chosen. Obligatory location is the corners of the house and the intersection point of all the walls: the facade and internal partitions (the grillage must repeat the ground floor plan). Additionally, piles should be laid in places of mandatory reinforcement of the foundation under heavy equipment of heating and water supply systems:

-

brick stoves and fireplaces;

-

cast iron fireplace inserts and high-power stoves;

-

solid fuel boilers of high power (including bunkers for a continuous supply of fuel).

-

heat accumulators;

-

accumulators.

How are piles produced for the foundation? What are the features of the pile foundation? Pros and cons of the pile foundation:

It can be interesting! In the article on the following link read about the pile-screw foundation.

Conclusion

What kind of foundation is needed for a foam concrete block house should be solved by a specialist - geological surveys, design and construction requires a professional approach. Any error at this stage, which leads to a decrease in the strength of the base, may be the cause of the destruction of the entire structure. And an excessive margin of safety is unjustified expenses.