To protect the roofing space from moisture, for the construction of modern homes used waterproofing film for the roof. The article provides information about the purpose, properties and varieties of this material. It also describes the main stages of installation and selection criteria. This information will allow you to choose the right material and avoid unnecessary costs.

Purpose of waterproofing a roof

Moisture can penetrate any roof covering. Precipitation find the gap in the joints of slate and ondulin. Gusts of wind blow water droplets under the tiles. Condensation of vapors emanating from living rooms also significantly increases the humidity of roofing materials. Even the most modern insulation is not able to protect the premises from dampness, cold and other negative factors caused by wet coating.

The main purpose of the waterproofing film is to protect roofing materials from excessive moisture. The right choice and professional installation affects the safety of the entire coating, repeatedly increasing its durability and durability. This is because the excess moisture can cause rotting of the wooden elements of the truss system, which can lead to the destruction of the finished roof structure.

Summarizing the above, the main functions of the film waterproofing of the roof are determined. They are as follows:

-

protection of wooden elements of the roof structure from moisture penetrating under the roofing outside due to precipitation;

-

protection of the building from the effects of vapor , rising from inside premises.

Roll materials for roof waterproofing are presented on the construction market in a wide range. To determine the optimal variant suitable for a particular structure, one must clearly know the properties and conditions of use of the membranes.

Properties of a waterproofing film

Some homeowners are afraid of quite tangible costs that accompany the installation of the material in question. However, the correct choice of film waterproofing can eliminate the extra problems arising from the premature destruction of the coating. Particular attention is recommended to meet the basic requirements for the material imposed by compliance with a particular type of roof. When determining which membrane to choose for the roof, the following qualities should be taken into account:

-

the material must have moisture impermeability - to protect against the effects of precipitation and condensate;

-

an important property is resistance to ultraviolet , which protects the film from damage by sunlight;

-

waterproofing material for the roof must have the ability to preserve the intended qualities regardless temperature conditions ;

-

durability of the coating increases due to increased mechanical strength of the film, tested for tear resistance;

-

due to anti-condensate characteristics of the material, the roof structure is protected from the negative effect of vapors rising from the residential premises;

-

elasticity of film waterproofing allows you to withstand significant stress caused by the installation and subsequent operation of the roofing.

The proposed list is only a brief list of the necessary qualities that the coiled material should have to protect the roof system from moisture. Let us consider in more detail some properties that characterize the waterproofing film for the roof.

Selection criteria

When building a house, each owner counts on the durability of the building. Therefore, it is important to pay due attention to the quality of materials, without paying special attention to their cost, so as not to be like the mean, forced, according to the proverb, to pay twice.

The waterproofing membrane for a roof has a number of specific characteristics that are recommended to consider when choosing a suitable material. Some of them require detailed consideration.

Preservation of the original properties under the influence of sunlight

The effect of ultraviolet radiation on many waterproofing films is expressed by the acquisition of increased fragility and brittleness. Therefore, one of the main selection criteria is the stability of the membranes under the influence of the rays of a merciless star.

Although in the final version of the finished roof, the membrane waterproofing of the roof is protected from direct sunlight by several layers of other materials, unforeseen situations occur during the installation process. So an unplanned delay in construction may cause the film to remain uncovered for an indefinite time. Ultraviolet combined with the wind can cause the destruction of the structure of some materials, negatively affecting their protective characteristics. First of all, the strength of the membrane and its resistance to moisture are affected.

Professional builders recommend choosing a waterproofing film that is UV resistant. This parameter is indicated on the packaging provided by the manufacturer. It should be noted that not all expensive membranes are characterized by a similar quality, breaking down in the sun.

Lifetime

When building your own home, the owner has the right to rely on its durability. By investing a lot of money in the future home, you should not save on waterproofing. Of course, you can choose a cheap membrane, which in a few years will collapse, thereby causing the truss system to be destroyed for unplanned repairs. It would be much more expedient to purchase a waterproofing film from a proven manufacturer with an impeccable reputation won due to the high quality of the products supplied. Such manufacturers are not afraid to indicate on the package an approximate lifespan of the rolled material. The absence of this parameter indicates the manufacturer’s uncertainty about the quality of the goods, and such an acquisition will become an unreasonable waste of money.

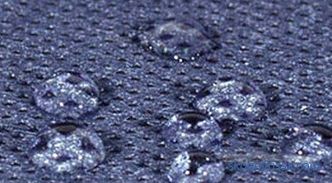

Anti-condensation characteristics

Laying a metal coating on the roof structure after pre-warming causes a large amount of moisture to form in the under-roof space. For such cases, it is recommended to choose membrane waterproofing with the effect that prevents the accumulation of condensate.

A film of this type has a special layer made of cellulose. Thanks to him, moisture is absorbed and securely held until certain conditions. These are either an increase in the strength of the wind, or an increase in temperature, contributing to the evaporation of condensate. To facilitate the process by fixing the counter grille, special gaps are formed that separate the membrane from the roof covering, as well as the waterproofing film from the insulation. Such ventilation speeds up the evaporation process.

The positive qualities of anti-condensate films include increased strength and resistance to ultraviolet radiation.

vapor permeability

This criterion is necessary take into account when the roof is completely insulated or when building an attic with the subsequent planning of living rooms. The mold formed in the layer of insulation due to accumulated moisture is a sufficient reason for the destruction of the wooden elements of the truss structure. In addition, the condensed liquid significantly reduces the insulating characteristics of the material. Therefore, for such situations waterproofing is best suited, the membrane of which has the property of insulating steam.

A cold roof protects only the roof structure and the attic space, which has a separate ventilation system. For such cases, a conventional film waterproofing is sufficient, without any special qualities that affect the cost of the material.

On our website you can familiarize yourself with the most popular sites in the Moscow Region for the construction of a country house . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

Types of under-roofing roll waterproofing

A curious fact, but most recently with The construction of private houses in Russia has not paid due attention to protecting the roof from moisture. The experience of using film waterproofing, borrowed from foreign colleagues, is currently very popular with domestic builders, significantly extending the term of trouble-free operation of the roofing system. This is facilitated by an extensive selection of roll material offered by manufacturers.

Many owners of private properties are interested in a film for the roof of the house, which is better suited to a particular building. Let us consider in more detail the most popular types of products under consideration.

Polyethylene film

With the development of the chemical industry, polyethylene has become firmly entrenched in the domestic market. Many building materials are made on its basis. The roofing waterproofing, the film of which is made on the basis of polyethylene, has several modifications. Among them, the most common are the following subspecies:

-

high-strength polyethylene membrane that does not have vapor permeability, prevents air and moisture penetration, and requires separate ventilation due to gaps that separate it from the outer layer of the coating and internal insulation with the help of a contra-lattice;

-

microscopic holes promote excellent transmission of water vapor, protecting the insulation from unwanted moisture in a perforated film having an alternative name "hydro-barrier" or "anti-condensate membrane". The maximum term of trouble-free use of such material reaches 25 years;

-

fiberglass mesh, closed on both sides with high-density polyethylene, is the structure of the reinforced film, characterized by high strength.

Such material was most widely used for waterproofing greenhouse roof structures. The reinforced membranes are more reliably fixed on the truss system, without causing excessive sagging. This contributes to improving the efficiency of moisture removal from the interior of the roof, despite the lack of this sub-type of plastic film of vapor permeability.

It may be interesting! In the article on the following link read about waterproofing the floor in a wooden house .

Polypropylene membranes

More pronounced strength, supplemented by UV resistance, which characterizes the material used to make such films, allows for a long time to protect the interior of the attic from precipitation. This allows you not to hurry with the installation of the top layer of the coating, preparing for the most efficient implementation of the process.

Due to the hygroscopicity of viscose-cellulose fiber deposited on one side of such hydro-barriers, the condensate that accumulates near the surface of the insulant is completely absorbed. Further elimination of moisture occurs under the influence of natural airflows circulating inside the roofing pie.

When installing polypropylene membranes, the viscose-cellulose layer should face the insulation. In addition, to ensure ventilation, it is necessary to observe a gap between materials of at least 5 mm.

Pergamin

The unique properties of parchment allow it to be used for isolation from moisture and steam. Liquid bitumen used to impregnate the material prevents wetting. Natural ingredients used in the production of glassine, contribute to the absence of the greenhouse effect. The main basic component is cellulose.

Many owners involved in the construction of their own home are attracted by the ecological purity of the parchment roof insulation. Also advantages of this roll material include simplicity and ease of installation, supported by low cost.

On the modern construction market, pergamin is represented by three modifications. They differ in the quality of the raw materials used, affecting the final cost of production, and the abundance of impregnation with bitumen. The most expensive is the "breathing" parchment, represented by the marks P-350. It is he who participates in the formation of a ventilated roofing pie.

It may be interesting! In the article on the following link read about how to choose waterproofing for roofing - a review of materials, prices .

"Breathing" membranes

They are the most expensive material of all the films under consideration. However, costs are offset by the quality and durability of products. In addition, the absence of the need for a contra-grille is attractive, since the perforated membranes allow fixation directly on the insulation layer.

The synthetic fibers that form the basis of the nonwoven fabric provide excellent protection against wind and moisture. In contrast to single-layer membranes, two-layer "breathing" films can be fixed on the insulation by either side.

The division of the considered type of roof waterproofing material into three categories is based on different levels of vapor barrier. Manufacturers provide the following types of "breathing" membranes:

-

the lowest vapor permeability are pseudodiffusion films .This material requires the arrangement of the ventilation gap between it and the insulation;

-

the average level of vapor transmission is characterized by diffuse membranes ;

-

high vapor permeability is the hallmark of superdiffusion films .

The following video will help you make the best choice of film coating suitable for waterproofing specific type of roofing.

Installation Features

First of all, you need to follow heightened security measures, since the roof arrangement works at height. Extreme care is the key to health.

In general, the process of laying a hydrobarrier truss system is not particularly difficult. Even the beginning master will cope with similar work. The main condition for the successful implementation of all manipulations is the presence of a construction stapler and a certain number of metal brackets.

Like all construction measures, installation of a film sheet for roof waterproofing requires preliminary preparation. A good result is guaranteed if the following rules are observed:

-

the minimum distance between adjacent rafters should be 1.2 m;

-

it is prohibited to carry out work in wet weather ;

-

it is required to form a gap with a minimum size of 40 mm between the barrier and insulation;

-

the film web is fixed in the direction of from the bottom up with a slight overlap of about 15 cm;

-

eventually the laid film should slightly sag to a depth of about 20 cm.

It can be interesting! In the article on the following link read about prices for waterproofing, vapor barrier for roofing .

There are self-adhesive membranes on the construction market, which are fixed by heating with a torch. All activities for the installation of profile film can be divided into several main stages. Each requires separate consideration.

Stage 1

The roof surface is freed from foreign objects. The rolled web is evenly distributed on the plane, taking into account the overlap. Stripes of the required size are measured, after which the film is cut.

In the video you can see the installation of a waterproofing membrane:

Stage 2

the membrane is fixed with a construction stapler. On top of the nails are fixed thin slats, ensuring better contact of the roll web with the base.

In the video you can see the installation of the waterproofing film:

Stage 3

Since the roof is not a perfectly flat plane, and there are additional elements on it, like chimneys and ventilation pipes, it is impossible to evenly distribute the one-piece hydro-barrier barrier. Therefore, in the required places the film is cut. To seal the edges using a special tool pasty consistency. The same purpose is served by a special adhesive tape used in the area of the valley and other complex elements of the roof structure.

The following video shows the installation of Tyvek membrane waterproofing:

It might be interesting! In the article the following link read about a country house with a veranda .

Conclusion

After reviewing the variety of waterproofing films, having studied their quality characteristics, you can make the right choice of material that meets the requirements of a particular structure. A useful recommendation is to ignore cheap products. All costs are undoubtedly compensated by the long-lasting reliable operation of the roofing system, providing peace and comfort to your home.