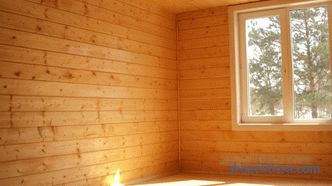

The only logical option for finishing a log house or a log house is wood paneling. Of course, the walls of the bathroom and the bathroom can be partially or fully tiled, and at the sink and stove of the kitchen's working triangle, an apron can be made from a tile, but no more. All other surfaces must conform to the overall style. And the most common way is to finish the walls with clapboard in a wooden house. The installation itself does not take much time, and the choice of wood types and profile of the panels is very large.

Grading of the clapboard

Under the general name "clapboard "in the catalogs of manufacturers and sellers there are at least a dozen varieties of wooden cladding boards. And since there is no single standard, and each domestic manufacturer works according to its own technical conditions, they all differ in size and type of profile. Even in determining the grade of the lining according to the quality of the wood and the cleanliness of the surface treatment, there are certain "liberties" of interpretation.

Important! It is necessary to determine which wall paneling is better for interior decoration of a house only on the basis of their own ideas about classes and quality. "Premium" or "extra" is from the evil one. Sellers simply try to attract a buyer with such big names.

According to the “old” domestic GOST (for specialized parts made of wood) there are two grades. They conditionally divide products into "transparent" and "non-transparent" coatings. In fact, there are two varieties - I and II.

Eurolining (which is not necessarily brought from Europe) must comply with the European standard DIN 68126, and there are three varieties - A, B, C.

Our manufacturers added more intermediate ones - "AB" and "BC". And in practice, for interior cladding at home, you have to choose the lining in a non-standard range of varieties: "extra", "A" or "AB".

Choice of lining

Conventionally, the entire range of lining can be divided into four large classes:

-

Domestic profiles . The easiest is a board in a quarter. It is rarely used, as there is no convenient spike-to-groove connection. More common profiles are "standard" and "collective farm" ("calm"). In the first case, the chamfer is standard at the ends of the faceplate (at an angle of 45 °), in the second case it is rounded.

-

Lining . It features a deeper groove and the presence of a "shelf" in front of an elongated spike. There are also two versions: standard lining has beveled chamfers on the front surface, "soft line" - rounded.

-

Imitation of a bar . By type of profile - this is a typical lining "standard", but only more powerful. And although there are coincidences at the boundaries of the size ranges, the difference lies in the purpose. Imitation of a bar is used when when finishing it is necessary to keep style of "bar-shaped" house. Therefore, this type of panels is mainly mounted horizontally (and the paneling is more often - vertically).

-

Block House . The scope of application is the same as for imitation timber. But in this case, the front surface of the panel has an oval profile, which, when mounted, repeats the wall relief of a rounded log. For the interior trim choose the thinnest panel. They are mounted exclusively horizontally.

If, for the most part, facade cladding is made of softwood lining, the choice is much wider for the interior. In addition to the "popular" pine or larch, you can find offers for the sale of clapboard from cedar, oak, linden, ash, and even exotic overseas species.

For living rooms there are no restrictions on operating conditions and humidity conditions. The only room where high humidity and wet conditions are dangerous for wood is the bathroom. In this case, it is better to use the lining with factory processing - the usual technology of "staining" with antiseptics protects only the top layer, and vacuum impregnation in the factory makes the wood in the "mass" invulnerable to moisture and fungus, including from the wrong surface. Another modern version of the "factory" protection - heat treatment of the panels.

Good to know! Impregnation is one of the most effective impregnation methods, since air is removed from the pores of the impregnation process and the antiseptic solution is “pushed” in its place.

There are also such types of lining profiles as "land house", finca and the whole subspecies of "wooden wallpaper", differ from ordinary lining and eurolining by a complex relief of the front surface. These are decorative wooden panels that are used in dosage form for finishing small areas.

On our site you can familiarize yourself with the most popular projects of wooden houses from construction companies represented at the exhibition "Low-Rise Country".

Technology

The finishing of the clapboard inside the house can be decomposed into several basic steps: preparation, installation of the batten, panel fastening, installation of additional profiles.

Preparation and installation of the batten

The clapboard cladding of the interior walls of a wooden house takes place on the batten. And this is one of the few opportunities for the hidden installation of electrical networks. Of course, you can stretch cables and wires under the floor surface or in the attic over the ceiling, but the vertical sections to the outlets and switches must be pulled along the walls. And this is not a brick or building concrete blocks - it is very difficult to cut a channel in a log or a bar of a house already standing, especially considering the constant “breathing” of a wooden house.

And here the main thing is to properly lay the cables and install the socket. The peculiarity of a wooden house is that all cables of power circuits with hidden wiring on a combustible base must pass through metal pipes (steel or copper). These are the requirements of the EMP. And the wall thickness should ensure the localization of the cable during a short circuit - the pipe walls should not “burn out” from the arc. Therefore, neither plastic nor metal corrugation is suitable here.

On our site you can find contacts construction companies that offer home insulation service. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

The first stage of the preparatory work is the laying of pipes, the installation of metal boxes for sockets and switches. And already on the basis of the diameter of the pipe and the height of the boxes, choose the cross-section of the bar for the batten.

The paneling must be delivered in advance so that the wood can adapt to the operating conditions. Usually they last for several days, even if the wood is sustained and has a normalized own humidity.

Required! If the wall panel is packed, it must be unpacked.

During this time, the crate must be treated with an antiseptic.

The next stage is marking for the crate. The wall paneling is usually mounted vertically, and the block house and imitation timber - horizontally. Crate do perpendicular to the panels.

Note! Sometimes the clapboard is placed diagonally. In this case, the crate can also be made vertical, but with a smaller pitch.

The pitch of the lathing of the batten depends on the thickness of the panels - the larger it is, the wider the pitch. The recommended range of the layout is 50-80 cm. And the specific value is chosen such that from the corner to the corner the bars of the batten stand at approximately the same distance.

Concise and accessible about the three main mistakes of the preparatory stage are described in the following video:

It can be interesting! In article on the following link read about the interior decoration of the frame house.

Installation of the wall panel

The finish of the house with the wall paneling in each room starts from the corner that is “visible”. In this place, both walls should converge equal, and preferably intact, panels. But if at the other corner the plating will end in a very narrow strip, this will look unattractive. Therefore, before starting the installation, it is necessary to calculate the number of whole panels and the width of the "remainder". If it turns out to be narrow, then installation should begin with a trimmed panel.

If the panel is whole, then the spike into the corner. Fastening to the crate from the side of the spike is carried out with thin nails, which are driven in at such a distance from the angle that their caps can be closed with a decorative corner.

On the side of the groove, the paneling is fixed to the crate with clamps.

The next panel is inserted into the groove first. If a bathroom or a bathroom is veneered, they are not driven to the end, leaving 1-2 mm to compensate for dimensional changes during humidity fluctuations.

The entire sequence of works is shown in the video:

Important! Also, it is not possible to jointly join the lining panels for the inside finishes home seasonal residence.

Features of interior decoration with a block house and imitation of a bar

Only thin and narrow panels of this type of wall paneling can be mounted on the blades, other sizes can be mounted on nails or self-tapping screws.But if the wooden house is of seasonal residence, and in winter there are “arrivals” in it, then it is better to choose traditional mechanical fasteners anyway.

There are two mounting options with self-tapping screws:

-

open method - for thick panels;

-

through the base of the spike , or the hidden method (for panels of average thickness).

For decoration House block corners use one of four techniques:

-

gash panels at an angle of 45 °;

-

through docking bar with a side equal to the thickness of the panel in the wave;

-

using a wooden corner or two planks connected by an angle;

-

fitting the panel on one side of the wall to the profile of the other wall, but for this, the layout relative to each other is shifted by half the width of the panel .

It is the latest version of the docking that allows you to get the most reliable imitation of the room inside a wooden frame of a rounded log. Although the performance of figure cutout will require a certain skill in marking and fitting. And it will take more time.

It can be interesting! In article on the following link read about facade panels for exterior home.

Conclusion - an option in an extreme case ...

There are other options for finishing a wooden house: batten panels of fiberboard and PVC. But they are used extremely rarely - only when there is an urgent need to make repairs at the lowest possible cost. Hardboard does not tolerate high humidity, and the laminated surface is easily damaged. Plastic wall paneling in a wooden house will naturally only look in the bathroom or bathroom.