Wooden houses are the most eco-friendly and favorable for human life. No wonder, wood is almost the first material that began to be used for the construction of housing. Modern technology has given this material new features and improved its properties. Using various processing methods, timber is made of wood for the construction of houses of various sizes and structures.

Reasons to choose a timber for building a house

A timber from timber makes it possible to exclude some properties of wood that complicate the construction process and make it more laborious. Lumber made of a unified profile and length. Fold the house out of it quickly. If you carefully calculate the required volume, you can avoid unnecessary waste of material, which will significantly reduce the estimated cost of construction.

Glued laminated timber is not subject to shrinkage, does not crack from the impact of the surrounding climate. It does not lose properties during long-term operation. When laying a bar with flat edges, a flat wall is formed, it is easy to cover it with a material for decoration or insulation.

Types of lumber for home construction and sizes, advantages and disadvantages

Let us see what kind of timber can be for building a house. There are 4 types of material:

-

non-profiled from an array;

-

non-profiled glued;

-

profiled from array;

-

profiled glued.

Conventional construction timber

This option is a log blank with rounded side semicircular edges. They are given a cross section of a square shape, with a side size of 100 to 250 mm. Before use, the material is dried in natural conditions.

It is impossible to call its use in construction the best solution. Suitable for the construction of simple buildings. It has certain disadvantages, we list them:

-

natural drying wood is subjected to shrinkage, warping and cracking during operation;

-

loose connections of the bars to each other to a friend leads to the need to insulate and seal the gaps between them after a while;

-

the material is not subjected to finishing, so you need to finish the surface to get a beautiful and neat wall;

-

requires additional strengthening of the bearing walls and corners of the house;

-

impregnation brazing composition for imparting fire design and bacterial resistance.

Of course, this is a fairly cheap and widely available material. If you agree to incur additional costs in order to refine it to the necessary qualities, then this option will be quite acceptable.

Profiled bar

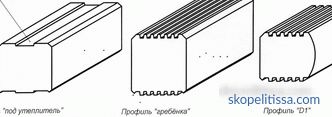

The same whole logs are used for it, as for ordinary planed logs. Processing is carried out on woodworking equipment with precise settings. It provides a perfectly smooth surface and perfect dimensions.

gaps. first, the sawn logs are dried to 22% moisture and less, and then they are further worked with them. Connecting planes have a comb or tongue and groove. At contact of a comb at the next bars, the dense joint between wreaths turns out. The tongue and groove allows you to lay insulation in it, which creates a tight connection of the crowns, not allowing air and moisture.

One of the drawbacks of such material is the preservation of wood defects that may exist inside the log, and the mandatory time for shrinkage, as it is inherent in all types of wooden structures.

On our website you can familiarize yourself with the most popular projects of double-bar houses from construction companies represented at the exhibition “Low-Rise Country”.

Glued laminated

This option has a calibrated cross-section, the connecting surfaces are made in the form of a comb or spike. Sometimes it is given the shape of a rounded log - D-timber. Externally, the wall of it looks like a natural log house, which is now very popular.

Such material is made of individual wooden plates, they are glued together with a special adhesive under pressure.It has a number of positive moments, namely:

-

A well-finished surface has a finished look, does not require additional finishing. The presence of locks, creates a dense wall without cracks.

-

The design of the timber eliminates distortion, it does not crack and is not subject to deformation during operation.

-

The constructed building does not shrink. This significantly reduces the duration of work on its construction.

Disadvantages:

-

The high price of the material, compared to a conventional bar.

-

The glue included in the bar makes it less environmentally friendly.

-

The microclimate in the house will differ from the conditions arising in a real wooden structure. In houses made of laminated wood, ventilation

should be done. On our website you can find contacts of construction companies that offer the service of building houses from a double beam. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Bar LVL

The technology of its production is similar to the production of glued timber. Only the material used is different. For the manufacture of take veneer from various trees, 3 mm thick. In the adjacent layers of veneer the direction of the fibers coincides.

This is a durable and flexible material, but very expensive. It is used to perform individual designs of the house. In most cases, to build from it the whole house is unprofitable.

Which timber is better for building a house should be determined taking into account the requirements placed on it and the availability of material resources from the developer. A well-dried and properly processed ordinary planed timber will serve no worse than expensive laminated material.

For the features of the LVL timber and its use in construction, see the following video:

It might be interesting! In the article on the following link read about the projects of houses.

Types of connection of the timber

When constructing a log house, it is necessary to connect individual elements when crossing at an angle or if the elements are not long enough. Use several types of compounds.

The most popular and convenient are connections with residue and without residue, in a cup or in a tooth.

Connection with residue

One-way connection. One side of the timber is cut across the element, the width of the file is equal to the width of the element being joined. This is the easiest and most frequently used method.

Quadrilateral connection is the most difficult and most reliable and accurate. Propyl make from all sides of the bar. The building is assembled as a designer - quickly and efficiently. In this case, all sizes must be strictly observed, the cuts are made strictly at right angles.

Connection without residue

This view has many options. We give often used.

Butt joint. It is carried out when using studded metal plates, they are fastened with nails or staples. For this purpose also use the connecting keys, which are well fixed joint, not allowing the bars to move and turn.

It is good to use the spike connection. The spike can be in the shape of a triangle or a trapezoid. Popular root thorn. On one of the bars cut a groove, in the other cut a spike, the corresponding size. With this connection, you can use the insulation of vegetable felt or jute fiber.

It might be interesting! In the article on the following link read about duplex projects.

Choice of timber thickness for building a house

The nomenclature of standardized timber dimensions has the following values: 100, 150, 200, 250 mm. The main requirement in determining the thickness of the walls of the house - it must give a certain strength of the structure, have sufficient heat capacity to create a favorable climate in the house.

To determine which timber is best for a 150 or 200 mm house, you should know which house you will build. For a single-story building, a thickness of 150 mm is sufficient. If more will be done exterior finish or wall insulation, it is undoubtedly.

For two-story buildings, a more solid and rigid structure is needed. In this case, a section of 200x200 mm will be justified.

For the construction of a house for seasonal living in a country house or a bath, if you do not make them warming, use a timber with a section of 150x150 mm.

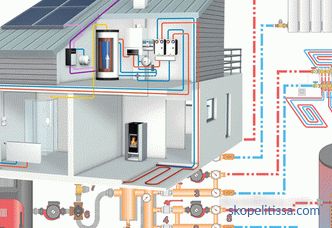

If you build a residential structure for the permanent residence of people will have to be heated. The walls of such a block house must be insulated, otherwise it will not meet modern requirements for energy saving.

It is known that the thermal conductivity of wooden walls depends little on their thickness. The difference between the walls in 150 and 100 mm of timber, will be 12% heat. From this we conclude that the insulated walls can be made thinner.

How different types of timber can differ:

What to consider when choosing a timber: the basic rules

Using the correct material - the key to successful construction. This also applies to wooden structures. What first of all we pay attention to when buying it:

-

Decide beforehand from which timber to build a house. A single-story house has enough material with a section of 150x150 mm. When erecting two-story structures, consume a bar of 200x200 mm.

-

In the country version, use a simple planed timber, pre-dried in a natural way. For a residential house need glued construction. Suitable timber with profiled compound, dried in the chamber.

-

Attention should be paid to product quality, it should have the correct symmetrical shape of the section, there should be no unevenness and curvature. Variety, choose A or AB.

-

Use the bar of the D-profile instead of rounded logs.

It might be interesting! In the article on the following link read about the projects of houses for narrow areas.

Conclusion

The choice of material must be determined at the design stage, taking into account all the situations that arise. You should not save unnecessarily by purchasing cheap material for a residential house in which you will live permanently. Modern high-quality wooden timber will allow you to build your dream home.