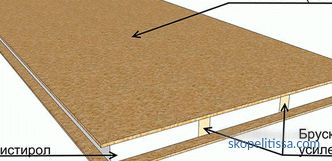

The SIP-panel (Structural Insulated Panel) is a unique and high-tech building material, represented by a three-layer structure of two plates of rigid material and an insulant located between them. The connection of the layers is carried out using a polyurethane adhesive component, under the influence of an external press having a pressure of nineteen tons.

The three-layer structure of an SIP-panel.

This innovation, which came from Canada, has recently been presented on the Russian construction market. Objects and houses erected by CIP-technology are distinguished by high assembly speed and excellent operating performance. In detail, how to build houses of CIP panels consider in our article.

Basic variations of sandwich panels

Depending on the type of thermal insulation material, SIP panels are divided into three categories:

- Three-layer panels using mineral wool Raw materials are distinguished by a high level of safety due to the increased refractory properties of the material used for their manufacture. This eliminates the likelihood of fires. Along with this, the high capacity of wadded raw materials to absorb moisture leads to the settling of the structure, loss of the original shape and deformation.

- Polystyrene raw material has water-repellent and highly eco-friendly performance. Expanded polystyrene is very light, making it safe to use for both the core and the supporting structure. However, it is worth noting its low fire resistance compared to glass wool raw materials.

- Polyurethane foam CIP panels have low thermal conductivity. But despite this, it is low ecological and has extremely low flame retardant characteristics compared to the two types presented above.

House from SIP panels.

Houses on CIP-technology: advantages and disadvantages

Despite the fact that such building material as sandwich panels is used in our country less often than traditional brick or wood, now You can highlight all the pros and cons, which has the technology of building houses of vulture panels.

House of SIP panels with decoration.

Advantages of the technology of assembling houses from CIP panels

Construction of houses in this way, has passed numerous tests for quality control. The technology of assembling a house from CIP panels is a good choice, due to the following advantages:

- High insulation of plates. Houses built using CIP-technology are distinguished by the degree of thermal insulation, which is much higher than that of a brick. To achieve a low coefficient of heat loss of brick raw materials, the thickness of the supporting element is about 3 meters, with the condition that the standard panel thickness indicator is 18 centimeters.

- Excellent noise insulation performance. Styrofoam does not allow street noise into the room.

- Low weight of the finished structure. One square meter of this design has an average weight of 20 kilograms. For comparison, a similar area of brickwork can weigh up to 500 kilograms. Because of this, housing built on Canadian technology does not require a strong foundation.

- The shortest possible construction time. The installation technology of CIP panels is easy to implement, they are made in a very short time. You can build a building in a few weeks. For example, it will take about three weeks to build a two-story house using turnkey CIP technology.

- The high mechanical strength of the structure makes it possible to withstand large longitudinal and transverse loads.

A house of CIP panels at the construction stage.

The main disadvantages of CIP panels

Sandwich panels have a wide range of advantages, however, at the same time they have their drawbacks:

- The inability to carry out free circulation of water vapor. For this reason, buildings need high-quality ventilation systems.

- Low fire resistance of some categories of sandwich panels, therefore, it is recommended to carry out an additional installation of a fire alarm system and pay special attention to the issue of insulation of electrical wiring.

- This raw material is not resistant to moisture. It is recommended to design a fairly wide foundation to protect the building from damp.

Important!

All the conducted studies indicate that very often the material’s deficiencies are due to poor-quality raw materials from which the panels are made, as well as a violation of their production technology . That is why the choice of CIP panels must be approached very carefully, and it is best to entrust the entire process of building a house to a proven construction company.

Construction of a house using CIP technology.

Technology of building houses from CIP panels

Technology of building houses from CIP panels consists of the following steps:

- Laying the floor. At the first stage, it is necessary to apply a waterproofing material on the base and install the bars or boards that will be the basis for the floor. After that, arrange the distribution of the panels over the entire area of the building so that the corner joints of the first panel and the construction bar coincide.

- The connection between the lumber and panel raw materials using self-tapping screws. The joints between the tiles are filled with foam.

- Assembly of bearing elements of the structure. The guide contour here will be a bar that is attached to the ceiling. After this, grooves are drilled through panel overlappings and timber, and this element is connected to the house foundation with fastenings. The first panel is fixed on one of the corners of the building, after which a mounting foam is applied to the connecting groove of the next panel and two panels are joined at a right angle. Similarly, carry out the installation of the remaining elements of the future building. Where on completion of the installation procedure it is planned to locate window and door openings, the structure is strengthened with the help of a bar. Fasteners and polyurethane foam sealant are used to interface the plate and frame part.

- Installation of the roofing part. According to the technology of building houses from modern CIP panels, the installation of the roof requires only one thing: to lay the panels on the ridge beam and the power plate, and then fix it with roofing screws.

Mauerlat is a roofing element, a wooden crossbar (beam) located along the perimeter of the external walls and connecting the roof and walls of the house into a single durable structure. If the construction uses a metal frame for the roof, the wooden crossbar can be replaced with iron beams.

About how the construction of a house from SIP panels is going on, the video will show more clearly:

The assembly technology of a house from SIP panels is simple and inexpensive. . It allows in the shortest possible time to build an inexpensive country cottage with excellent thermal and sound insulation performance. At the exhibition of houses "Low-Rise Country" a large number of projects of houses built using CIP-technology are presented. Here you can visually see that a sandwich panel is a building material that is not inferior to brick or wood.

Rate this article, we tried for you