The pile foundation is becoming more and more common for modern housing construction, which is due to its reliability and relatively low cost. Many people imagine piles in the form of steel pipes with threads that need to be screwed into the ground, although initially the pile foundation was created from "nails": wooden, and then reinforced concrete, which were simply driven into the ground. If wooden piles are a priori non-durable and their use is specific, then we asked about the reinforced concrete experts for more details on the pile foundation expert - the head of the sales department of HELIXPRO, Marina Yuldashev.

What is the difference between reinforced concrete piles and steel piles

If the project Your house is designed for a pile foundation, then depending on some criteria, the construction company may suggest to mount a pile field of screw or reinforced concrete piles. If you turned to professionals, the difference will be explained to you, but just in case it is advisable to understand the subject of discussion yourself.

Bearing capacity

The most important advantage of a reinforced concrete pile is that it can hold a much larger mass than the screw one. If the metal, for example, you can load about 5 tons, the concrete will already hold all 50-60.

What affects the price

If you simplify it a lot, The production of screw piles is the cutting and welding of metal pipes and billets with their subsequent painting. In modern production, all these processes are already automated, which allows you to keep a relatively low price tag.

In the manufacture of reinforced concrete piles, a reinforcement cage is put into the mold and all is poured with concrete. Then it takes some time for the concrete to harden, and after stripping it is necessary to wait for the material to gain design strength. It is very important to comply with all technological standards, because if the iron pile is gradually twisted into the ground, the concrete in the literal sense of the hammer in the ground. And if the pile is able to withstand a load of several tens of tons, you can imagine with what efforts the copra hammer hits and how important it is that the strength of the pile itself fully complies with the design one.

This results in another component of the price tag - in addition to the fact that transporting reinforced concrete piles is more complicated and costly, they also cannot be installed manually.

The number on the pile field

is necessarily used. It would seem that if r / w piles capable of withstanding a load 10 times greater than those for which steel is designed, then for a light house you can use a smaller amount and thereby save money.

Unfortunately, this is not the case, and the problem here is not even in piles, in the so-called trim, which is put on piles and in fact is already the foundation of the house. The fact is that any material - wood, steel or concrete, if it lies on support points that are more than 3 meters apart, will inevitably begin to deform over time - to bend.

By the way, even 3 meters is the maximum possible distance, which is not suitable for all materials. Typically, the standard is the installation of points of support (piles) at a distance of 2 meters from each other (if the project or geological exploration does not indicate another).

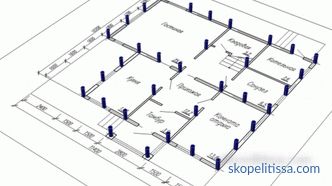

As a result, regardless of the material of the used piles, they should be hammered into key reference points (usually, these are the angles and the intersection of the bearing walls) and between them, so that the distance between the piles does not exceed 2-3 meters. For example, if the width of a house is 10 meters, then the piles are clogged in the corners and between them 3-4 more piles are needed - at a distance of 2-2.5 meters from each other.

Service life

In order for steel piles to last as long as possible, they must be carefully processed - depending on the protection used, their service life is 30-50-80-120 years. Reinforced concrete piles do not require any protection for themselves, as the steel grid in them is already in the thickness of the concrete. Therefore, the service life of reinforced concrete piles depends solely on the quality of the materials used - if everything is done according to GOST, then reinforced concrete can last more than 100 years.

For example, the estimated service life of Helixpro reinforced concrete piles is 150 years and the manufacturer gives them a twenty-five year warranty.

Difficulties in using reinforced concrete piles

If steel piles can be screwed by forces of 2-4 people, then reinforced concrete must be hammered with the help of technology. This means that the use of reinforced concrete piles is very difficult in areas with a large slope, on which it is almost impossible to fit piling machines. It will also be very difficult to use reinforced concrete piles to install, for example, a pier.

Of course, if necessary, all these problems are solved. But in some cases it can cost a fairly large amount, which is likely to make the use of reinforced concrete piles unprofitable.

How to choose the right w / piles

Since the foundation is a very important part of the house and the stability and durability of the whole building directly depends on its characteristics, then everyone without exception is interested in the question of how to choose the right w / b piles. There must be some rules - where to look, what to feel and so on. ..

The answer is banal, but unfortunately or fortunately, it is the only one: through personal inspection - no .

In order for this answer to be as clear as possible, you need to accurately imagine the whole chain along which the pile passes - from manufacturing to the construction site.

Firstly, the basis of any of its own is the metal frame, which is still at the production stage, is set into a mold and then poured with concrete. Of course, it is very important how high-quality steel is used for this framework, but to see that inside your piles will not work.

Secondly, the quality of the concrete is very important, of which the pile itself is. This concrete must not only stand in the ground for the entire measured pile service life, but initially also withstand shock loads when driving the pile into the ground. Even if you have the skills to distinguish between visually distinguishing good concrete from bad, then you need to understand that no one can give a guarantee only on the basis of an inspection.

As a result, you will receive the guaranteed quality of concrete piles only if the manufacturer provides a documentary guarantee for their products. And this, in turn, is possible only for certified production, which adheres to all the required GOSTs and other requirements.

About the production and use of reinforced concrete piles Helixpro, in the following video:

Conclusion

Reinforced concrete piles rightfully occupy their niche in the construction market. They are distinguished by their versatility and relatively low cost, plus, in some cases, reinforced concrete piles there is simply no alternative. But when choosing where to buy the future foundation, be sure to pay attention to the reliability of the manufacturer. From the availability of all the necessary documentation and warranty design depends on the life of your home.

| Additionally The exhibition “Low-Rise Country” houses sincere thanks to Marina Yuldasheva - Head of Sales at HELIXPRO - for her help in creating the material. HELIXPRO is an expert in pile foundations. If you need more detailed advice, you can use the following contacts: website: helix-pro. ru tel. : +7 (800) 500-57-97 |