Constructions made of concrete and brick are considered the most durable. But, if the house is very durable, but cold, then the future owner is unlikely to please it. Brick and concrete walls do not keep heat well, so they must either be built thicker or insulated. To combine strength and thermal insulation properties in a single material, cellular concrete technology was developed. It is for her produced foam blocks. The structure of such material is not monolithic, but porous. Air bubbles inside provide insulation and sound insulation. Therefore, the projects of houses and cottages from foam blocks - a compromise solution, in which materials are selected with the optimal combination of these parameters.

Two-storey project of a house 7 by 7 from foam blocks

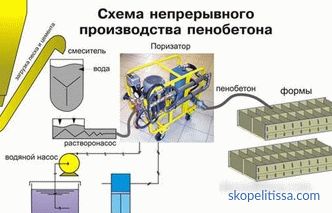

Production technology of foam blocks

Foam concrete is used as material for foam blocks . Its main components are the same as that of simple concrete - sand, cement and water, but in addition to these components, a frother is added. The most commonly used foaming agents based on natural protein components, they are more durable and environmentally friendly. Synthetic compound blowing agents are also used, their cost is lower, but they are considered to be of lower quality.

Production sequence.

-

Foam preparation. The foaming agent is poured into the foam generator, mixed with water, compressed air is supplied, under the action of which air bubbles are formed.

-

Kneading a foam concrete solution. Sand, cement, water is poured into the mixer, everything is thoroughly mixed. After obtaining a homogeneous plastic mass, foam is added to the resulting dough and mixed again.

-

Molding. The resulting mixture is poured into molds and left to dry for 12 hours.

-

Drying. After the blocks gain primary strength, the molds are disassembled, the blocks are placed on pallets and sent for final drying. This happens in the premises, at a certain temperature and humidity level, takes a process from 8 hours to 2 days.

Production scheme of foam concrete blocks

What kind of buildings can be built from foam blocks

Light summer houses from this material to build unprofitable, its main purpose - the house to stay at any time of the year. The only restriction is the height of the building - it is not recommended to build above 3 floors. Although this is possible if the supporting structures are made of a more durable material. In addition to residential buildings, summer kitchens, garages, warehouses, outbuildings and hangars are built from foam blocks. Also, this material is convenient to use for extensions to existing buildings.

Extension from foam blocks to an already operated house

Pros and cons of ready-made house projects

Currently, all construction companies offer their clients both standard designs of foam concrete blocks and individual ones.

The main advantages of finished projects are as follows:

-

Time saving. There is no need to wait for the project to be completed. All the necessary drawings, instructions and layouts already exist.

-

Budget savings. All engineering and architectural calculations have already been made, in addition you will not have to pay for them.

-

Buildings for ready-made projects have already been built somewhere. This means that if errors and omissions were found, they were corrected and reflected in the documentation.

-

A ready-made project can be customized. If the changes are not significant, it will be done for free, the essential ones will have to be paid.

House with an attic of foam concrete according to the standard project

The only thing that can be attributed to the disadvantages of standard projects - lack of external identity. But, if it is so necessary, you can show imagination and add uniqueness to the house with the help of additional decoration and landscape on the site.

Typical or individual project - what to choose

There is no definite answer to this question. It all depends on the needs and financial capabilities of the customer. Ready-made projects of foam concrete houses will be much cheaper than exclusive ones that should be ordered if the external architecture is important in the first place and nothing from the catalog has attracted you. Or in the case when changes are assumed that are comparable to the cost of a new project. In most cases, you can find a compromise option and choose a ready-made solution.

It should also be understood that the finished projects are made taking into account the climate of the region and the characteristics of the local soil. The project by the individual order quite possibly should be finished while building. In any case, do not rush.Specialists of a construction company will always answer customer questions and help you make the right choice.

Overview of the characteristics of foam concrete blocks, see the video:

The construction sequence is not much different from the construction of buildings from other materials. It all starts with the foundation, ends with roofing and finishing.

-

Foundation. According to the technical requirements specified in the project, the structure is prepared and installed. The most commonly used monolithic foundation tape type. Waterproofing is laid over the foundation.

-

After the foundation is ready, the first row of blocks is laid. This stage is very important, the surface of the foundation is almost never ideally even. To make the first row straight, cords are stretched along the masonry and horizontalization is controlled with the help of the building level. For the first row is usually used the usual mortar, it allows you to compensate for the unevenness of the foundation. Subsequent rows are sealed with glue for foam concrete.

-

Masonry reinforcement. 2 options are used - reinforcement with rods and meshes. The rods are stacked every 2-3 rows in the cut channels (grooves) filled with mortar. The grid is laid through 3-5 rows, and smeared with a solution, with this method, the grooves are not required. Be sure to reinforce the first row, the blocks under the window openings and areas of high load.

-

Overlaps. If the building has more than one floor, hollow slabs of ordinary concrete or gas concrete are used. The first option is used in cases where the distance between the walls exceeds 6 m. If there is no such limit, the most reasonable option is aerated concrete slabs, they are lighter and retain heat well. In single-storey houses, floors are made of wooden beams.

-

Wall insulation. To save internal space, the insulation is fixed outside the building. At this stage, a frame for future cladding is attached to the walls of the building. The facade is covered with a layer of primer, glue is applied, and insulating plates are fixed from bottom to top.

-

Facing the facade. Most often it is made of natural and artificial stone, decorative plaster, facing brick, siding. Facing is attached to the frame prepared in the previous step.

On our site you can find contacts of construction companies that offer the service of building foam block houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Tape foundations for house 6 by 7 from the foam block

Facing the house from foam concrete by brick

Attic in houses from foam block

Houses with an attic are becoming more common not only in the projects of cottages from foam blocks and country houses. Many urban high-rise buildings are built with attic floors. The additional floor under the roof provides the following benefits:

-

Additional living area of the building. It is cheaper to build a room in the attic than to expand the area of the building or build an additional floor.

-

Multifunctionality. The room on the attic can be adapted for different purposes. In addition to rooms for household use, such as a bedroom or pantry, here you can equip a workshop, a study or a smoking room.

-

Easy installation of communications. No additional branches are required, everything starts from the lower floor.

-

Reduced heat loss. Attic insulation at the same time is a heat insulator for the roof. The cost of heating the attic is small, heat rising from the lower floors almost completely heats it.

-

External aesthetics of the building. There are many architectural options for the execution of different shapes and sizes.

A small country house of foam blocks with an attic

Houses with an attic are well suited for people leading an active image life, which is not difficult several times a day to climb and descend the stairs. For large and multi-family residents, additional space will be most welcome.

It might be interesting! In the article on the following link, read about which concrete blocks are best for building a house.

What influences the prices of projects for buildings from foam blocks

You can buy a project for a house from foam blocks within 20000-30000 rubles. The cost of creating an individual project is determined depending on many factors and it is impossible to call it in advance. The main factors affecting the final cost of the project are listed below.

Seismic activity of the terrain

In areas of increased danger, a more stable foundation is required, and rates for masonry are increased.With special risks foam blocks are replaced with other materials.

Foam concrete house - the initial stage of construction

Climatic conditions

The average annual temperature, humidity level, quantity are taken into account precipitation. It is necessary for heat engineering calculation, choice of material for walls and exterior finish. In regions where the average daily temperature in the winter period is below -20 ° C, the insulation of the roof is also required.

Geological features of the area

The soil composition, groundwater level, and depth of frost penetration are taken into account. If necessary, geological surveys are conducted in the period of intensive precipitation - in the fall or spring.

Construction budget

If there are restrictions on the means, projects are chosen without additional extensions and architectural decorations. The less complex protruding forms in the project, the more reliable the building will be. Foam blocks have low resistance to tensile loads. Only specialists can correctly calculate the uniform distribution of the load at their asymmetric arrangement.

Stages of building a house of foam concrete, see the video:

The need for energy saving

Properly designed house does not require additional insulation, even if built in a single layer of blocks. Heat losses depend on such factors as the number and size of windows, the location of rooms relative to the cardinal points. If energy efficiency is in the foreground, then the window size is minimal, non-heated premises and outbuildings are located on the north side. If the main task is the exterior of the building, balconies, verandas and bay windows are added to the project. At the same time the area of glazing increases, the cost of heating increases.

Approximate prices for finished projects:

-

a small two-storey house of 104 sq. M. m - from 24 thousand rubles. ;

-

one-storey house with a terrace and an attic of 173 sq. M. m - from 27 thousand rubles. ;

-

two-storey house with a garage of 113 square meters. M - from 29 thousand rubles.

Examples of plans and finished foam concrete projects in the photo

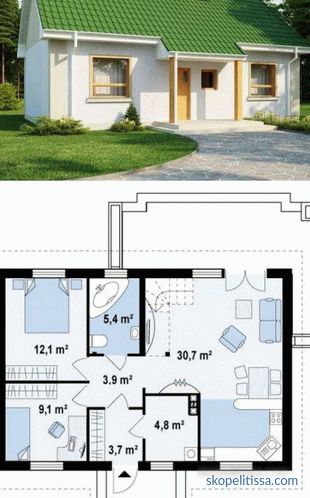

One-story foam block house according to the standard project

It may be interesting! In the article on the following link read about the insulation penoplex.

House with a loft of foam concrete with a living basement room

House with one residential floor - decorative plaster

a two-story building of foam blocks was used for finishing - the best option for a family of 3-4 people

A two-story foam house with a terrace and a detached garage for an individual project

It can be interesting! In the article On the following link, read about which house is cheaper to build - wooden or foam blocks.

Conclusion

Modern foam concrete houses are a worthy alternative to brick buildings. They are in the middle price range between budget wooden houses and capital ones made of concrete and brick. At observance of all construction norms and conditions of operation such a structure is guaranteed to serve for more than a century.