Today, the modern market offers a large selection of materials for exterior and interior decoration of buildings of any type, among which preference is often given to fiber cement boards. Despite the fact that this material appeared not so long ago, he managed to gain widespread demand among domestic consumers. A wide selection of textures and colors allows you to use fiber cement panels for interior decoration of the house and for refining facades.

Finishing the front of the house with fiber cement panels

Fiber cement panels - what kind of material

It is a modern building material, which is successfully used for cladding residential and public buildings. In the modern market, panels are represented by a large selection of textures and color solutions. Fiber cement can imitate various materials: stone, wood, brick and others. Facade finishing works with panels are carried out easily and quickly. Fastening can be performed on any type of batten, the main thing is that its creation should correspond to a certain technology manufacturer.

Products can be used for both interior and exterior. Often used as design elements - their use makes it possible to translate into reality interesting design solutions. The types of fiber cement panels presented on sale are divided according to the following parameters:

-

Fire resistance: high or normal;

-

Moisture resistance: normal and high;

-

Dimensions;

-

Surface of products: laminated or textured.

Variety of fiber cement panels on the market

Characteristics possessed by cement panels for facades:

-

The thickness is from 7 mm to 20 mm;

-

Weight 1 square meter from 13 kg to 20 kg;

-

UV resistance;

-

Service life more than 50 years;

-

Preservation of the original appearance for 20 years;

-

The degree of water absorption is up to 10%;

-

The material is non-flammable;

-

Length and panel widths from 0.45 m to 3.5 m;

-

Withstanding high and low temp Temperature: from -60 to + 80;

-

Density is high: from 1000 kg per 1 cubic meter.

Examples of textures of fiber cement panels for finishing

On our site you can to find contacts of construction companies that offer the service of building houses from fiber cement panels. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Where and why fiber cement panels are used

Composition, what the fiber cement board is made of, dimensions and appearance affect the purpose of the housing material. Such products are widely used in various fields of construction:

-

For finishing high-rise buildings. Fiber cement panels are distinguished by high strength characteristics; therefore, they are successfully used for cladding high-rise buildings. They are free to withstand high thermal and wind loads;

-

For exterior finishing of wooden houses and brick buildings. Facing allows you to safely hide all the defects that were made during the construction phase of the walls;

-

During renovation and repair. Thanks to this finish, even the oldest building will acquire a modern appearance;

-

The panels are successfully used not only for cladding facades, but also for interior decoration;

-

Fiber cement panels are the perfect solution if you want to build an interior partition.

The panels are completely non-flammable, which allows them to be used for cladding facades in those structures where fire safety and durability are paramount: educational institutions, hospitals and so on.

The use of fiber cement panels for cladding high-rise buildings

Strengths and weaknesses

Among The numerous advantages of the material are highlighted by the following:

-

Long service life, over 50 years;

-

High degree of moisture resistance;

-

The material perfectly resists temperature changes;

-

Excellent thermal insulation performance;

-

Environmental cleanliness;

-

Panels are 100% non-flammable;

-

Material will not melt when exposed to fire;

-

Excellent resistance ivost to sunlight;

-

A wide range of textures and colors.

Among the minuses of the material, one can name only the fact that it loses in appearance to decorative brick and tile, but otherwise it is perfect.

Facing the facade of the house with fiber cement panels imitating bricks

It can be interesting! In the article on the following link read about the CIP panel.

What types exist?

The material is represented by a large selection, but most often there is a house decoration with fiber cement panels for brick, stone and wood. Facing under a brick looks perfect on any buildings: country cottages, houses, offices, shopping centers and so on. You can choose a new brick imitation or aged, it all depends on the design of the building. Stone panels are the perfect solution in the case where it is not possible to use natural material. This finish looks very nice and solid. Plates that imitate wood are more often used for finishing the facades of suburban housing.

Production of material

Production of panels is carried out on the basis of two components: concrete and fiber. Concrete is used high-quality - due to its high degree of strength, the service life of the panels is more than 50 years. The second component is a mixture of cellulose and fiber. This component gives concrete a good porosity, which significantly reduces the weight of fiber cement plates, provides them with good flexibility and resistance to deformation. The production process takes place in several stages:

-

At the first stage, the extruder (the machine that makes the solution plastic) delivers the solution, then it is rolled into layers of small thickness. To give the required thickness, the layers are superimposed one on the other;

-

Sheets are sent under a press;

-

The plate is covered with a protective or decorative coating.

Production of fiber cement boards

Famous brands of fiber cement plates

Currently, in the domestic market such products are offered by a large number of manufacturing companies. The most reputed among them are:

-

"Eternit". Belgian trademark;

-

"KMEW", "NICHIHA". Products from the Japanese manufacturer are of high quality, long service life and visual appeal;

-

Latonite, Kraspan and Rospan fiber cement panels. Domestic trademarks widely sought after by consumers. The panels have high quality, good strength and long service life. High-quality decoration of the facade of a private house fiber cement panels of these brands in no way loses the foreign counterparts.

An overview of fiber cement panels with thermal protection, see the video:

How to store and cut material

The plates are delivered on special pallets. In the case when the unloading was done mechanically, the storage panels are left on the pallets. If the material is unloaded manually, then it should be stored on specially installed bars, which are spaced 40 cm apart. When stored in the open air, the plates are covered with a tarpaulin so that dirt and water do not get on them.

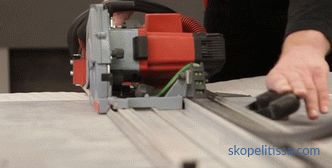

Sawing is performed using a grinder or a circular saw. The plate is settled in such a way that the front side looks up, after it is securely fixed. If the board will hang, then the cut will turn out uneven. Jigs can also be used for cutting panels. Here it is necessary to apply a hard metal file. It is very important that the pendulum function is disabled. With this cut, the panel is placed so that its front side is facing down.

Cutting the fiber cement plate

It might be interesting! In the article on read the following link about wood wall panels.

Mounting technology

Installation of fiber cement plates is carried out in several technological steps:

-

Detection of uneven facade;

-

Installation of brackets;

-

Installation of insulation material. It is best to use plate-type thermal insulation;

-

Installation of wind-proof film. Laying perform with an overlap of about 20-25 cm;

-

Assembly and installation of the frame;

-

Facing. We make a facade of fiber cement panels. Their installation is carried out on the frame.

For the installation process of fiber cement boards, see the video:

The creation of the framework must be approached responsibly. There are certain requirements that must be considered. For the frame used profiles of high-quality aluminum. Arrange it like crates. The basis on which the frame will be mounted must be well fixed to the wall, this is done when using brackets. The distance between them horizontally should be 60 cm, and vertically 100 cm.If additional warming is required, the insulation material is placed between the frame profiles.

It is very important to check the quality of fastening of each element. The material for the frame is chosen depending on the thickness of the plates. If they have a small thickness, then it is possible to use wooden blocks for arranging the crates. If the plates are heavy, then you will need to use a metal frame.

Frame installation before installation of fiber cement panels

Installation steps for plates

-

Before starting to work on the facing of the facade, determine the number and amount of irregularities on the wall. For this, a geodetic survey is performed, then the surface of the walls is marked and the installation of beacons is carried out;

-

According to the beacons, brackets are mounted on anchors or dowels. The horizontal pitch is 1000 mm and the vertical is 600 mm. The length depends on the thickness of the insulation placed on the walls;

-

Insulation is fixed. Here you can apply insulation boards or mineral wool. The thickness of the insulation layer should be from 10 to 15 mm. Next, a vapor-permeable membrane is mounted;

-

At this stage, the installation of profiles and guides is performed. Steel profiles are U-shaped, horizontal - L-shaped, and Z-shaped are used as vertical intermediate. They are fixed perpendicular to each other, this allows us to give the structure the desired rigidity. In order to fix the profile on the brackets, use rivets or screws. As soon as the metal subsystem is installed, installation of fiber cement panels is performed.

Installation scheme of fiber cement panels

Installation plates around doors and windows

In order to revet places around doors and windows, it will be necessary to arrange an additional frame that will frame the structure on all sides. To create it you will need a metal profile. Installation is made with screws. To dock, you will need to trim the edges of the individual plates. Trimming is done at an angle of 45 degrees. At the end of the installation in the places where the connections were made, you need to go through the sealant. Also for the arrangement of door and window openings, you can apply a decorative profile. Its fixation is performed directly to the box of windows and doors, then the plates themselves are mounted into the grooves.

It might be interesting! In the article on the following link read about concrete panels.

Conclusion

The installation of fiber cement panels is not difficult, however, you need to know about all the subtleties and technological nuances of installation, without this, the lining will not be of high quality and will last for very short. In order not to redo the work twice, it is better to immediately find qualified installers who will competently and quickly do all the work.