A wooden house in a “rural” area looks as natural and attractive as a brick house in a city. Especially when the material for the walls is a rounded log. But the log is not cheap, and a lot of time must pass in order for the house to shrink and for finishing work. Therefore, often use other materials and technologies. And in order to create a reliable imitation of a log house, choose a block house for outdoor decoration of the house.

Block house - one of the best options for finishing the house

Block house as a type of facade wall paneling

By purpose , the method of fixing and connecting the block house is a kind of "lining".

In essence, the production technology can be represented as cutting out of a rounded log of a timber, as a result of which four “slabs” with the correct spherical surface will remain - they serve as a blank for the block house. It remains only to cut the spike on one side length, on the other - to cut and cut the groove. And of course, on the seamy side it is necessary to make grooves in order to relieve internal tension in the wood.

In addition to this, there is a manufacturing technology of "standard" lumber - boards or beams. But due to the large amount of waste, its cost will be higher than that of the traditional one.

Such a cutter cuts a block house from a bar or board

If we talk about grade, then this type of lumber has no domestic standards. But in practice, manufacturers have developed their own classification, according to which there are three "pure" options and two "mixed."

"Clean" options are A, B, C.

Grade "A" differs from "B" in the number of healthy knots per 1 m, their permissible diameter (15 mm versus 20 mm) and the absence of "black" knots and cracks. For grade "B", small and short cracks are allowed, plus a small number of "black", but not falling out knots.

Grades "C" and "BC" are not used for finishing houses, they are suitable for building fences or finishing household outlets somewhere in the back yard.

Cladding board - it's just lumber - its quality requirements are the same as for other works.

For outdoor house cladding, the block house take panels not less than 30 mm thick. And due to the peculiarities of massive sawn timber, it is almost impossible to find a “perfectly” clean house block 4-6 m long, which is why a “mixed” variety “AB” appeared. In addition, even when storing lumber, small defects in the form of shallow cracks may appear.

Sometimes there is another classification borrowed from European manufacturers: “Extra” (“Prima”), “A” “B” “C”. If we draw parallels, then "Extra" will be a "pure" variety "A".

With such a length, it is impossible to find the panel “without a hitch”, and for covering the facade you don’t need

Advice! Since there are no standards for a block house, manufacturers are free to assign any sort to their products. Therefore, when buying, you need to make sure that the declared quality meets your requirements.

Criteria for wood selection

Even the Block House vinyl siding has certain signs that testify to the quality of the facade panels. Wood is a more “thin” material, and in many respects the durability of the outer lining depends on the right choice. Therefore, it is not enough to evaluate the compliance of the variety - density, resistance to moisture and strength of wood are important.

Only conifers are used for finishing the house with a block house. Hardwood (linden, oak, ash) are used for interior wall cladding.

Larch is considered an elite material and its qualities a priori correspond to the operating conditions in the open air: high humidity and the effects of precipitation. The density and strength of Russian larch, as in the northern wood (still growing in Siberia), will also be at a high level.

Larch has dense and durable wood, so it is not in vain that it belongs to the coniferous elite

The pine is not so clear. Most of all, northern pine is suitable for facade decoration - its strength and density are much higher than those of wood from warm regions. And determine the origin of the pine block house on the distance between the annual rings - the closer they are to each other, the better. The quality criterion is at least three rings per 1 cm of the end cut.

On our site you can find contacts of construction companies that offer the service of finishing and warming houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

How to choose a width

There are criteria for choosing the diameter of a rounded log depending on the purpose and size of the house.

When building a small house for seasonal living (summer cottage, summer house), a log with a diameter of up to 220 mm is used, the visible part of which lies in the range of 150-180 mm.

For a "full-sized" heated house, the minimum log diameter is 240 mm, the recommended one is 260-280 mm. And the visible part is 190-210 mm.

To keep the "proportions", the width of the house block should correspond to the visible part of the log:

-

for a cottage - 140-150 mm (with a thickness of 28-36 mm);

-

for a large house - 190 mm and above (with a thickness of 36-45 mm).

Each board size has its own purpose

Plating options

Mounting method block Hausa only - on the vertical crate with a horizontal arrangement of panels.

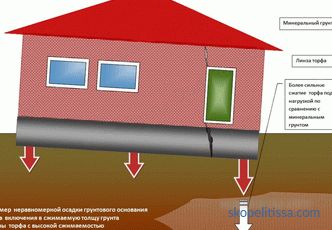

Crate is needed anyway. Even when a wooden house is sheathed, and there is a possibility of fixing the panels directly to the wall, a ventilation gap is required for weathering moisture (otherwise the wood will start to rot).

The issue of insulation is decided depending on the seasonality of living and materials of the walls. If this is a "summer" house, then the insulation is not carried out. It is also possible not to install heat-insulating materials when the house is built according to frame technology or from foam concrete blocks 40 cm thick.

Sheathing during the construction of the "skeleton", as another option use of blockhouse

In other cases, wall insulation is necessary - the costs will quickly pay off due to savings on heating and air conditioning.

It may be interesting! In the article on the following link read about imitation of a bar.

Features of installation

Despite being clapboard, the methods of attaching to the batten when external covering the house with a block house are different than during internal work.

Inside, narrow modifications of panels of small thickness (up to 20-22 mm) are used, and the operating conditions are characterized by the stability of humidity and temperature. Therefore, the block house can be fixed to the crate with flush-mounted fasteners - clamps. Exterior finish is carried out with a thick and wide cladding board, in which, with changes in humidity, there are such internal stress forces that it can simply be pulled out from the engagement.

You can see the video about the block-house finishing:

The second reason that does not allow using clamps for exterior cladding - the method of location of the block house on the facade. The groove for which the clip “clings” must look down (so that moisture does not get into it). And with such an orientation, the mounting of the panels on the clamps can only be conducted from top to bottom.

Therefore, cladding is carried out in one of two ways:

-

Open. The panel is screwed to each timber at two points - from the side of the groove and closer to the spike. Before mounting, drill holes into which screws are forced into screws so that their heads do not protrude above the surface of the panel. Then these places are stacked, masking under a small knot. This method of installation is the most reliable, and is recommended for thick and wide block house.

-

Hidden. The bottom panel near the groove is fixed in an open way, plus at the base of the spike they drill holes at an angle of 45 °, into which screws are screwed. Each subsequent row house block (except the last) is fixed only through the spike. The top row is fixed in an open way.

The spike mount makes the installation hidden

Note. Due to moisture fluctuations, the tree changes its size across the fibers - it swells or dries out. Therefore, it is necessary to ensure that during installation there remains a small gap between the stop of the groove of the upper row and the tenon of the bottom. If the workers miss this nuance, then over time the wall is deformed.

Features of the design

The cladding of the facade of a house from a house block is more complicated than from an imitation of a bar or planken. The reason - in the features of the "bulk" lumber. Panels with a radial surface are harder to fit together.

Connecting at an angle of strictly 90 ° requires jeweler's skill when handling wood

The most accurate way to increase the length is considered to be “counter” washed down block house at an angle of 45 °.

But more often they use a simpler version - a lath in the form of a lath or board. The place for him is chosen in such a way that it looks natural and is common to all the connected panels.

Spikes and angles from the slats - the easiest way to close the joints

Corner joints are also designed in a similar way - by connecting through the gash corner or overlay of two slats.

The final stage of the plating is surface polishing and varnishing or colorless paint.

For examples of finishing the facade with a block house, look at the video:

It might be interesting! In the article on the following link, read about siding block house.

Conclusion

As a result, on the basis of the above, it is clear that finishing a house with a block house is more difficult than with any other facade panels.To be sure of the quality and durability of the skin, it is better to entrust this work to professionals.