The subject of the article is laying paving slabs on a concrete pavement. The raised topic is very relevant today. After all, the main functional purpose of the blind area is to prevent precipitation from penetrating to the foundation. But today, the concrete structure does not meet the modern trends in the design of the suburban area. Therefore, the owners of private houses are trying to revet the blind area with various materials, where paving slabs are one of the popular options. So, in the article we will talk about the technology of paving concrete pavement paving.

Scaffolding of the house

It should be noted that the scaffold of the house is a structure that should be monolithic. That is, should not pass through itself moisture. Therefore, simply tile separately without a concrete base is not laid. The reason - the gaps between the cladding elements, through which water easily penetrates into the ground to the foundation.

Of course, at a cost, concrete blind areas are cheaper than covered with paving slabs. But beauty requires sacrifice, in this case money. Although it should be noted that such a plate structure has several advantages:

-

high decorativeness surfaces;

-

increases life ;

-

increased maintainability of material by dismantling the piece coating rather than the entire plane;

-

simplicity tile laying;

-

a wide choice of in size, shape and color.

Technology of paving slabs paving

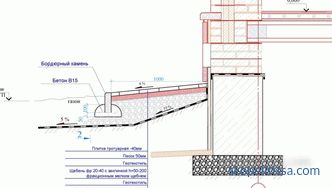

First of all, it is necessary to pour a concrete base. In fact, this is a concrete blind area. Its tab is based on the standard technology of pouring concrete solution.

-

Along the perimeter of the house a trench 90-100 cm wide is dug. The depth depends on the thickness of the layers of materials used to create the clay castle and the sand-crushed stone pad. If you plan to lay the paving slabs with insulation, it is necessary to take into account the thickness of the insulating layer.

-

So the trench has been dug. Its bottom is flattened and compacted .

excavated under the blind area on our site you can familiarize yourself with the most popular projects of stone houses from construction companies represented at the exhibition "Low-Rise Country".

-

Filled with clay with a thickness of 15-20 cm. It must be tamped in, adding a little water. It is at this stage that one must already think about the construction of a slope that does not exceed 5 °.

-

A waterproofing film is placed over the clay lock , the strips of which are laid out overlapping each other. The displacement size is 10-15 cm.

-

Beds are covered with sand , each of which is rammed and leveled. The sand cushion is 20 cm thick, if there is increased water saturation or heaveiness in the area, then the layer should be between 30-50 cm.

-

Gravel are covered with layer 20 see

-

On top of lay the reinforcing frame or from steel reinforcement with a diameter of 8-10 mm, or from a metal mesh.

-

Pour concrete solution . This is the base for paving slabs.

It would seem that it could be easier. But it should be noted that laying paving slabs on a concrete pavement is in fact not an easy process. Here you need to take into account a large number of nuances to ensure the high quality of the final result. Let's look at the process of forming a slab covering with all the nuances.

Nuances of the construction of the blind area of paving slabs

First of all, it is necessary to adjust the width of the blind area so that it fits in a border like a border element and the required number of tiles that will not be cut. For example, if the width of a tile is 30 cm, and the gap between them is within 1 cm, then when laying two tiles it is necessary to maintain the distance from the wall to the edge of the trench within 63-64 cm. This is without taking into account the thickness of the curb. That is, adding to this parameter the thickness of the curb stone, we get the width of the trench under the blind area.

Please note that if the wall or plane of the basement is uneven, then between the laid paving slabs and this surface it is necessary to leave a small distance within 1-2 cm. It will subsequently be filled with masonry mortar.

On our website you can find contacts of construction companies that offer extension services to existing houses, reconstruction and other turnkey work.Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

With regard to mounting the curb. It is usually laid on a sand pillow. And then the trench is poured with rubble. But it is necessary to take into account the dimensional parameters of the limiter. This refers to its height. That is, first of all, they determine at what height the curb will stick above the ground surface. And already the rest of it is lowered into the trench. The moment is really very important. Thickness of preparation will depend on it: a concrete and sandy layer.

In order to dig a trench itself, it is necessary to mark it. That is, the above parameters are applied to the ground. In the corners of the blind area set the pegs, which are tied with twine. And only after that, the soil is removed with a depth determined by preliminary calculations, as shown above.

The next stage after the creation of the sand cushion is the installation of curbs. The important point is that all elements of the border construction are set strictly horizontally. It should be noted that the curb stone is installed on a concrete solution. Optimally, if the stone sinks into the solution to a depth of 10 cm.

The video shows how to form a sand cushion for a pavement slab:

Before pouring the concrete solution, it is necessary to install separation elements. To do this, use boards with a thickness of 20-40 mm. Their length is equal to the width of the blind area from the wall to the curb, the installation step is 3-6 m. If the length of the wall is small, the separation can be made only in the corner of the structure, connecting the corner of the building with the angle formed by the two installed curbstones. The separation of poured concrete is the compensation gaps in the event of thermal expansion of the material.

Next, lay the reinforcing frame and pour the concrete solution. It is important to clearly maintain the depth of concrete pouring. That is, the distance for laying paving slabs and the dry mix, the thickness of which varies within 3-4 cm, must remain up to the upper edge of the borders.

It can be interesting! In the article on the following link read about flagstone for paving paths.

And one more thing concerning the pouring of concrete. It is with his help that the angle of inclination of the blind area of paving stones or paving slabs is finally formed. The easiest way is to lay 2-3 cm along the wall at the level of the upper end of the curbstone. This will be the upper part of the blind area. Lower - upper edge of the curb.

Flooded concrete must be at least 48 hours long. Only after that you can proceed to laying paving slabs around the house.

Installation of paving slabs

Laying of tiles is carried out on a dry mix. These are 3-4 buckets of sand and 1 bucket of cement. The mixture is poured onto a concrete base with a thickness of 5-6 cm. Next, the tile is laid, which is embedded in the cement-sand mixture with blows of a mallet. At the same time, the mixture will be compacted, and the tile will settle down to a depth of 2-3 cm. That is, it will become flush with the curb.

It is important that all elements of the laid finishing material are located in the same plane, the masters use a rule or a flat board. Do not forget that the paving slabs must be laid in an inclined plane.

As soon as the tile is laid, it must be watered. It is impossible to do this with a hose under pressure. Optimally - use a watering can or a wound tip on the hose. Because a large pressure of water washes away the cement-sand mixture, and this is a high probability that voids will form under the slab material, which will reduce the quality of the final result. Ideal if the surface is watered several times. This will increase the bonding strength of the tile with the dry mix.

Next, the cement-sand mixture is scattered on the surface of the plate facing and swept with a brush. This is done for one reason - to fill the gaps between the tiles with fastening solution. And again, the whole blind area is watered from a watering can.

If the roof of the house is equipped with a drainage system, then it is necessary to install a concrete reflux for each vertical pipe drainage system. This is a finished groove, which is installed during the installation of paving slabs. The installation method is exactly the same: on a dry mixture at an angle.

The video shows the sequence of ongoing construction operations for the construction of a concrete blind area with laying paving slabs:

It might be interesting! In the article on the following link, read about whether a basement is needed in a country house — features, for and against.

Installation of tiles on a ready-made blind area

The variant when there is the task of laying paving slabs on a ready-made concrete blind area that has been in operation for many years is identical in technology. But there are also specific nuances. First, such a blind area is a finished design without curbs.Secondly, after long-term operation, it requires repair.

As regards the repair process, everything depends on the quality state of the concrete structure. If it is scuffed, small cracks or notches, then the problem is solved with a standard cement-and-sand repair mortar in the ratio of 1: 3. Flaws are simply filled with a solution. With significant defects from the blind area it is better to get rid of, having built it again.

So, the concrete structure has been repaired. Now you need to purchase and install curbs around the edges. Under them dig a trench to the width of the building element. The installation depth is determined so that the upper edge of the curb stone protrudes above the concrete pavement to the height of the paving slabs and the dry mix. This necessarily takes into account the pillow of sand and gravel 20-30 cm thick and a layer of concrete fastening mortar, which is poured under a curb.

The process of laying paving slabs is no different from the above . That is, the installation is carried out at an angle to the dry mixture using a mallet or a rubber hammer.

It might be interesting! In the article on the following link, read about outdoor stairs and garden paths hanging in the air.

Conclusion on the topic

I would like to note at the end the fact that not all craftsmen use waterproofing film from the pavilion construction. But we must pay tribute to this inexpensive material, which creates another waterproof barrier to precipitation in the form of water, which penetrates even through the smallest cracks or pores. Sometimes even a monolithic concrete foundation does not save the foundation from the harmful effects of moisture. Therefore, laying paving slabs on waterproofing is the best option.