The article describes the soft membrane roof - its advantages and features, types of materials. The classification of roofs by material and purpose, the device of the roofing pie, technology and installation stages, prices.

The roof protects the whole house from external factors. Excess moisture goes through it, important life support systems pass through. That is why you need to choose high-quality materials that will protect this structure for a long time.

What is a roof membrane?

A membrane is a type of film material that is used for coating. It has a thickness of about 2 mm, consists of polymers. An excellent option is considered for mounting the roof on flat and flat roofs. Less commonly used in the construction of houses with sloping roofs.

Advantages and disadvantages of membrane roofing

For the first time these coatings were used more than 40 years ago. During this time, products have not lost popularity. It is actively used in Europe, gradually increasing in popularity on the territory of Russia. This is due to several advantages of the material.

Benefits:

-

Durability . Service life varies from 20 to 60 years.

-

Fire resistance . The structure includes fire-fighting components, excluding the ignition of the material.

-

Heat- and waterproofing .

-

Low weight . On flat roofs, the load on the load-bearing structures and the foundation should be minimal.

-

Resistance to external environmental factors such as low and high temperatures, precipitation, high humidity, ultraviolet radiation, and others.

-

Vapor permeability . Moisture vapor appears under the roof and condensation forms. Moisture, remaining in the layers of the roof, begins to destroy the entire structure. Membrane coating eliminates this outcome, increases the service life of the roof.

-

The coating can be used on uneven surfaces.

Disadvantages of membrane coatings:

-

High cost compared to other coatings. But this disadvantage is covered by an important advantage - durability.

-

Low resistance to some solvents , oils and substances produced on the basis of bitumen. This is taken into account before installation.

-

Some products contain volatile substances .

On our site you can find contacts of construction companies that offer the service of performing all types of roofing works of any complexity. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Types of roofing membranes

As with other products, several types of roofing membranes are on the market. They differ from each other in composition and purpose. Therefore, before using a particular type, take into account its characteristics.

Classification by material of production

Manufacturers make products based on different polymers. As a result, coatings with distinctive characteristics, properties, advantages and disadvantages are on the market.

Views:

-

EPDM . As the basis of the canvas used dense rubber or polymerized elements. Increase the strength of the product with a special polyester mesh. Essential fibers are added to the composition in order to increase the resistance of products to mechanical stress.

The membrane has a number of advantages, among which we can distinguish water resistance, environmental friendliness and resistance to weathering. The main disadvantage is that the seams are joined by an adhesive method, which reduces the strength and reliability of the web compared to other types.

-

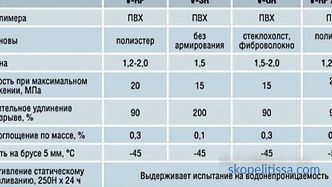

TPO . The most hermetic and resistant to high temperatures material. There are two models. The first type is created without reinforcement. The second has a reinforcement with polyester or fiberglass. The canvas has the characteristics of plastic and rubber. It has several advantages. Of the benefits can be noted a high level of strength. The disadvantage is the low elasticity and the need for timely service.

-

PVC . The most common and popular product among polymeric coatings. Increase the strength of PVC membrane for roofing with essential fiber. Give elasticity and increase resistance to low temperatures by adding plasticizers. This type of product occupies a large part of the market; it is produced by many roofing manufacturers.

On our website you can find contacts of construction companies that offer a range of construction services without prepayment. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Classification by purpose of roofing membranes

All roofing membranes are divided into several types according to their purpose. They are used in different layers of roofing structures.

Membrane types by purpose:

-

Breathable . The canvas protects the roof from precipitation from the outside and, at the same time, releases moisture and condensate from all roofing layers. Fabric made from synthetic fibers. For one-sided moisture transmission make special holes of microscopic size.

-

Vapor barrier . Produce a sheet of polyethylene. Designed to protect the remaining layers of the roofing pie from moist air leaving the premises. With this protection extend the life of the entire roof.

-

Polymer . A good option for roofs with a soft roof. Make of elastic high-quality polyvinyl chloride. This is a durable waterproof coating.

-

Anti-condensate . The material is used to absorb condensate from the roofing and further output outside the structure. This feature was obtained with a combination of polypropylene material and waterproof spraying.

-

Superdiffusion . The coating protects the internal structure from the effects of external factors and brings out the moisture that forms in the under-roof material. It has high strength and flexibility.

To increase the life of the entire roof and remove moisture from the premises, several types of coatings are used. A vapor barrier is used as the bottom layer. As a top coat, another type is used to remove moisture from the roof itself.

On our site you can find contacts of construction companies that accept maternity capital as payment. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Roof construction

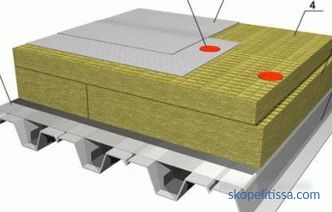

The roof consists of several layers, including membrane material. For convenience, experts began to use the concept of "roofing pie". It consists of 3 important parts: vapor barrier, insulation and waterproofing. The entire device roof membrane consists of several layers.

Structure of the membrane roof:

-

At the very bottom is the base of the roof . The diagram shows a professional sheet.

-

Then a thin vapor barrier is put. Thin film that protects the insulation from possible moisture. With its help, the service life of the whole structure is increased.

-

Then the first thermal insulation layer is placed. Often, mineral wool is used as insulation.

-

Next comes the second thermal insulation layer . Insulation share is not accidental. For this layer, mineral wool of high strength is used, which serves as a load balancer.

-

Fix these layers with telescopic fasteners.

-

The upper layer - roofing membrane .

This design changes, increases the number of layers, using different materials. They come from various factors, including the roof characteristics and climatic conditions.

Technology of installation of membrane roof

Properly chosen technology of mounting membrane roof will increase the service life of the whole structure. Several methods are used, based on the type of coating and the foundation of the roof.

Technology of mounting the membrane roof in video:

Glue method

Suitable for EPDM type membranes. During installation, use special double-sided adhesive tapes. They glue the joints between the canvases. For work do not use serious professional equipment. Gluing takes a little time.

The glue method has one serious drawback - the tightness of seams is quickly broken. Over time, the tape begins to depart, which leads to the ingress of moisture under the roof.

It may be interesting! In the article on the following link read about roofing materials for the roof.

Ballast method

The method is based on ballast from pebbles, gravel, paving slabs or other material. This method is used for installation on flat roofs. Also, do not exclude the possibility to carry out work on structures whose slope does not exceed 15 o .

The application of this technology is possible only on strong supporting structures. They must withstand a lot of ballast weight.

The basic steps of installation:

-

At the base of the roof, which is prepared for installation in advance, a membrane coating is laid.

-

Glue the joints between the layers and fix the material.

-

Ballast is poured onto the membrane. Guided by the rule - at 1 m 2 place at least 50 kg.

Before mounting the membrane roof, pay attention to the angles of the ballast. If there are sharp objects, then a nonwoven fabric is placed on the membrane. He put protection against possible physical damage.

Use of heat welding

Material joints are welded with heated air. For work, use special welding equipment, which creates a stream of air heated to a temperature of 600 o . This method is suitable for fixing TPO and PVC membranes.

Parts of the coating are laid with overlap on each other, heated air is heated and glue the edges together. When the material cools, it turns out a solid canvas with hermetic and elastic seams.

It can be interesting! In the article the following link read about the types and prices of soft roof for the roof.

When laying PVC, the membranes adhere to a number of rules:

-

The membrane surface thoroughly clean of all contaminants. Only after cleaning begin sealing the seams.

-

Strictly observe the set temperatures . If you increase the temperature, the material will begin to burn. As a result, it will not stick together.

-

The device without delays is conducted along the web. Monitor the maintenance of optimal movement speed. If a thick seam is formed, a probability of rupture of the membrane near this place will appear.

-

The canvas is laid without stretch . The overlap near the lying parts must be greater than 5 cm.

-

Adhere to the optimal width of the seam - it must be greater than 2 cm.

Manufacturers and cost of coating

Roofing membranes from different manufacturers are on the market. Among the Russian companies known products "TechnoNikol" and "Stroyplastpolimer." The first manufacturer launches a three-layer PVC membrane on the market.

membranes Stroyplastpolymer produces two types of waterproofing products. The first type has a reinforced part and is used in the upper layers of the roofing. The second type in the composition of the 2 layers. It is used as a waterproofing material. The price of Russian companies starts from 400 rubles.

From foreign companies are known manufacturers such as "Sika", "Ruvitex", "Renolit" and others. PVC membranes - most of the products that are made by foreign companies. The cost of foreign products for m 2 starts at around $ 15.

The video shows the arrangement of the roof of a house with a wedge-shaped insulation and PVC membranes:

It might be interesting! In the article on the following link read about the modular home - telescope.

Conclusion

The use of membrane coating increases the service life of the whole structure. This material is combined with other elements of the roof to increase the technical characteristics of the roof.