Despite the comparative "youth", the technology of building houses from foam blocks is popular enough to be used by construction companies. Some of them know all about how to build a house of foam blocks, as they specialize exclusively in the construction of cottages of this material.

General information about foam block

is obtainedFoam block is a relatively young material, but already well proven in the market. This is molded foam concrete, which, due to the simplicity of production, is quite cheap.

By category, it belongs to heat-insulating materials (structural heat-insulating materials). The weight of one unit is highly dependent on such a parameter as the quality of the cement mortar from which it was made: for wall-mounted parts, the weight can reach 48 kg, for partition walls - half the values.

At the same time, when a house is made of foam blocks, one of them is enough to replace the section of masonry of 12-14 bricks, which greatly saves time and effort.

Characteristics of foam blocks

Foam block that has been used since the 70s It has proved itself well, thanks to such characteristics :

-

Good frost resistance is the quality most suitable for our latitudes;

-

Safety - the material is non-toxic in case of fire, and it burns badly;

-

Low thermal conductivity - and this, unlike the first point, will allow to keep heat inside;

-

A good and clear form of "bricks" - will allow you to do less Islands when laying, and they will be much thinner than ordinary bricks;

-

Ease of additional processing - blocks are easily sawed and drilled with conventional tools (hacksaw or drill) ;

-

Fast construction - again, due to the size of the blocks, the time costs are significantly less;

-

Sufficient sound insulating properties - useful in the home, even in private.

Special attention should be paid to the following moments :

-

When creating the masonry you will need to reinforce (to give additional rigidity to the structure);

-

The material is not intended for multi-level construction, the limit is 2-3 floors ;

-

Good absorbs moisture due to its structure, therefore, it is better to additionally protect buildings made of foam concrete with sheds and facades;

-

Laying walls is better than at a temperature of not less than +5 g adusov ;

-

transported and stored best material in polyethylene film , the storage space is also necessary to use (or overhang).

Pros and cons of houses from foam blocks

To build a house from foam blocks, you need to pay attention to the technology and features of the material.

-

By the advantages of the building, it will be possible to note extremely short construction time , in fact, provided that the pile foundation is possible, the actual time will be 1-2 months.

-

Houses from foam blocks are eco-friendly (non-toxic material);

-

Low weight structures allows build a lightweight foundation;

-

Cost , to which a country house of foam blocks costs: the price (compared to a tree, a house of similar area) will be 2-3 times cheaper ;

-

Blocks do not rot , are less susceptible to mechanical damage from rodents or insects;

-

these are building centenarians. With rock services foam concrete blocks are exactly 50 years old — some houses have been undergoing major repairs since the 1970s.

-

A large variety of architectural solutions

On our website you can familiarize yourself with the most popular projects of foam concrete blocks from construction companies represented at the exhibition "Low-Rise Country".

Disadvantages of foam block houses:

-

A fairly specific choice of materials for interior and exterior, not all are suitable;

-

The resulting house will be difficult to screw in screws due to the cellular structure of the material;

-

Increased requirements for insulation from moisture (house must be veneered immediately after construction);

Structure and features of foam concrete

Foam block is a parallelepiped of one of the fixed sizes.With a standard block length of 600 mm, the width and height can be different :

-

300 by 250 mm;

-

300 by 100 mm;

-

400 by 250 mm;

-

400 by 200 mm.

When building a house, it is recommended to use foam blocks of the right thickness at once, rather than typing walls of two or more pieces.

Foam concrete and foam concrete blocks also have marks (usually the following values appear on the package after the letter D):

-

100-300 - for internal thin partitions ;

-

400-600 - if you require thermal properties (they will not work for the supporting wall!);

-

600-900 - for the external walls (load-bearing) of the houses, they are suitable, structural foam blocks;

-

900-1600 - structural reinforced, ideally suitable for the bearing wall, but are significantly more expensive compared with the previous category.

Foam blocks are used to create the following designs :

-

Unreinforced and reinforced partitions;

-

Building blocks;

-

Insulation work;

-

Filling the voids;

-

Roofs and fences.

The quality of the cement slurry is simply determined - it is enough to rub the finished block. Better yet, take a piece of the block and try to grind it; poor quality material crumbles into dust. Color should be uniform, without inclusions and abrupt transitions.

On our website you can find contacts of construction companies that offer the service of building foam block houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

What is included in the project of the house

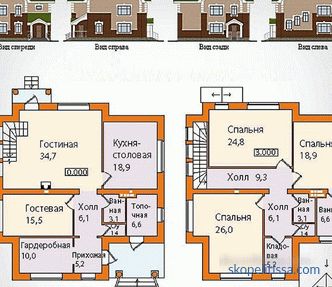

Foam block houses projects suggest low-rise construction. As practice shows, more is not needed, especially since by law we have the maximum permitted height of houses for country construction - 3 floors.

Projects may include support columns, but made from other materials (not foam concrete!). Also additional reinforcement of the foundation

will be required. The project of the house should include the following data:

-

All dimensions and, if available, slope angles of all structural elements (roofs, for example);

-

Additional structural elements (roof battens, duct wiring, for example);

-

Planning of all rooms and floors;

-

All engineering communications , their entry points;

-

Phased estimates indicating the quantity and cost of all materials;

-

Separately issued schedules ka facade with all windows.

Preliminary calculations and preparation for construction

When preparing, first of all, after the design and evaluation stage, you need to understand how much material is needed depending on the specification.

To calculate the materials for building a house from foam blocks. At a minimum, such data will be required:

-

height on all sides and corners;

-

length of the sides;

-

the thickness of the walls and the mortar itself, the mesh for the laying;

-

price;

-

density.

In addition, window and door openings are also taken into account in order to deduct them from the calculation, but it is usually advised to have a supply of material.

Before construction, the site for the foundation must be completely cleared, and technical requirements for the commissioning of communications are also prepared.

It may be interesting! In the article follow this link read about building brick ovens.

Foam blocks house: building over the summer

Building a house from foam blocks is not much different from building any other house, except for the stage of laying the material.How to build a foam block house correctly:

-

geological surveys are made (to determine the site’s engineering capabilities);

-

the plan (project) of the house indicating all sizes and subtleties (for example, columns and supporting elements cannot be made of foam blocks);

-

technical conditions are compiled to connect to the network (sewage, water, electricity, gas, other amenities);

-

marking of the boundaries is made to arrange the pit for the future house (taking into account the subtleties of the soil and open owls, which are possible on this type of soil);

-

when building in winter, it is necessary to foresee measures to prevent freezing of soil or working with frozen soil;

-

foundation is laid - in this case, it can be a choice of a belt, tile or pile-grill. The choice depends on the price and construction time;

-

after necessary work with the foundation, load-bearing walls are laid out (and cores with waterproofing;

-

interfloor floors, beams are installed, seismic belt is being worked out;

-

roofing is carried out - rafters are laid, fire-resistant treatment is carried out.The roof is used according to one of the following technologies - metal tile, profiled sheet, bitumen tile.

-

the facade is being made. Due to the special The remaining material should be assessed in advance of the creation of the facade in terms of moisture removal (so that the thermal conductivity of the material does not change due to environmental conditions);

-

installation engineering communications and internal finishing rooms.

These are the main stages of building a house from foam blocks, which will help you understand how and what should follow.

How a house is built from foam blocks clearly can be seen in the video:

It may be interesting! In the article on the following link read about the extension to the house of foam shackles.

How to revet a house from a foam block

The materials with which the house should be faced should not allow moisture inside, on the blocks themselves. These qualities have:

-

plaster (cons: fragility, complexity of application);

-

tile (for example, ceramic) - of the minuses, we can call the quick weathering of the tile solution under the influence of the weather, so you should not use such material for buildings with a high number of floors (more than 1 floor).

-

facing brick (minuses: time);

-

decorative stone (cons: low heat insulation, sound insulation);

-

siding (cons: comparative fragility).

Extension to the house

Another use of foam blocks is the rapid construction of extensions and economic structures. This is possible by two methods:

-

using an expansion joint (a separate foundation, in fact, a separate mini-construction, with its shrinkage, which, in view of another bearing area, may differ from the basic version);

-

rigid coupling (the design repeats the one that already exists, it is possible only with a tape foundation with adequate depth to avoid "walking" parts).

The first option seems simple, but you should also make a deformation seam of additional materials to ensure uniform filling of the voids between the buildings. Usually any rolled material is used “inside” and additionally an insulating sealant “outside”.

See how the extension to the house is done in the following video:

It might be interesting! In the article follow this link read about the exterior decoration of the house of foam blocks.

Conclusion

Summarizing all the above, we can say that foam concrete buildings are an economical, fast and fairly reliable option during subsequent operation even in the harsh conditions of the Russian winter. The material is not subject to change when temperature drops, it is convenient during construction, and its disadvantages are easily leveled during final finishing. If you are still deciding how to build a foam block house, then the best solution would be to contact a specialized construction company. Professionals will build a house quickly and efficiently, plus, they will give a guarantee on their work - not in words, but written in a contract agreement.