When it is necessary to put a “deaf” fence around the site, which will reliably protect against uninvited guests and curious glances, then a fence from the profile will best solve the problem. Moreover, the concept of "profile" applies to all elements of the fence: the pillars are made from a round or square shaped tube, veined (cross members) from a rectangular shaped tube, spans from a profiled sheet. And in order to characterize the advantages of such a fence, besides reliability, quick installation, corrosion resistance, long service life, attractive appearance and low cost can be called.

Simple, attractive and reliable site fencing

Choosing a pipe for supports and cross-pieces

If you go to design sampling "according to science", it is necessary to conduct geological surveys to determine the bearing properties of the soil, select the type of foundation (pile or solid) and calculate its parameters depending on the weight of the structure and wind loads.

In principle, there are such calculations, including for the collection of metal profiles. And since the height and width of the span in each case is not fundamentally different, that is, unambiguous recommendations on the size of profiles for pillars and veins. Moreover, the correctness of these sizes is confirmed by the long-term operation of existing fences from the profiled sheet.

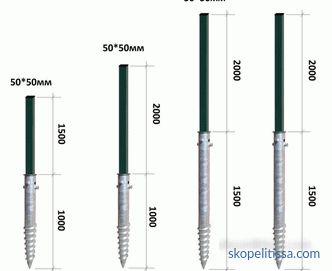

If you look at what is offered on the building materials market, the factory pillars have a wall thickness of 2 mm and a square profile with dimensions of 50x50 or 60x60 mm, and they come from a round pipe with the same cross-sectional area. But not always their length meets the bearing features of the soil on the site. Therefore, when it is necessary to order the manufacture of pillars with an "individual" length, then it is possible to focus on these dimensions of the section.

Using a square and rectangular profile allows you to assemble an iron fence without welding.

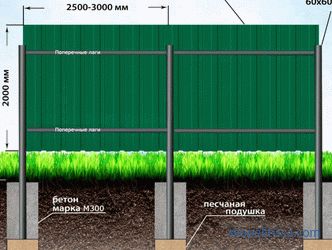

As the crossbars, a rectangular profile with dimensions of 40x20 mm and wall thickness 2 mm. And how many will be, two or three, decide depending on the height of the fence.

What should be the length of the column

The length of the column is equal to the sum of the above-ground and underground parts.

The above-ground part depends on the span construction. There are three options:

-

the pillar rises above the span;

-

the pillar ends at the upper border of the profist;

-

The pillar is 10-30 cm below the fence height.

The size of the underground part is determined by the soil properties:

-

for the heaving - post heel depth should be 20 cm below the frost line;

-

for loose - at least 1/2 the height of the fence;

-

for dense - at least 1 / 3 fence height.

Installation methods for pillars

The fence post performs two functions simultaneously. The above-ground part of the support pipe is the supporting element of the span construction, and the underground part is part of the foundation. And since the pipe is essentially a pile, the installation methods are the same:

-

Zabivnaya. Due to the high wind loads on solid fencing, this method is rarely used and only for dense soils. Often, a collapsible structure is used when only the underground part with the tip is driven in, to which the profile pipe is attached.

This is how the collapsible support looks like with the drop-in underground part

-

Screw. This is the standard technology for installing a screw pile in a lightweight form (with a smaller blade diameter). As in the previous method, there is an option collapsible design.

Screw support for the fence of two types of profile

On our site you can find contacts of construction companies that offer the construction of fences and fences. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

-

With partial or complete concreting of the underground part. This is the most common method, the technology of which does not dictate which pipes to take from the metal profiles - there are no shock or torsional loads for a solid pipe and there is no “binding” to the type of tip for a collapsible support.

A simple and reliable way to install supports for light barriers

-

Combined. Used for soils with weak bearing properties. The pipe is instilled at the calculated depth, and is "tied up" from above with a monolithic shallow-deeper foundation. This type of base is also used for combined fences, in which a column of brick or stone is laid out around the pipe.

The strip footing for the fence can withstand severe wind loads in open space conditions

The choice of profiled sheet

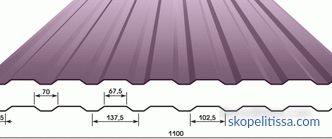

Typically, metal profiles on a fence are chosen from three types: C18, C20 and C21, where "C" means "wall" and the numbers are the height of the profile wave.Each of them has the best combination of price and strength, although more often they choose between C20 or C21.

Standard sizes C20

It might be interesting! In the article on the following link read about the fence from brick.

The low profile (C8 or C10) does not provide the necessary strength of the fence, and its main purpose is the sheathing of temporary structures used in sandwich panels, where rigidity is increased through the use of two sheets and insulation.

Can also be used in the construction of the fence profiled sheet HC35 or C44. Usually such a choice is made if increased strength to mechanical loads is needed, but such a high “wave” means greater metal consumption per 1 m of working width, and this affects the price.

The second selection criterion is sheet thickness. Without taking into account the coating, it lies in rather wide limits - from 0. 4 mm to 0. 8 mm. It is considered that for a fence it is enough 0. 45 or 0. 5 mm.

The third criterion is a protective coating. There are several types of polymer coatings that are applied to the galvanized surface of the profiled sheet. But not all of them are suitable for fences.

Obviously about the choice of professional sheet, look at the video:

Polyester. The most inexpensive type of coverage. But it is applied in a very thin layer, so it is easily scratched even during transportation and installation.

The second option that you should not choose is plastisol . Possessing high strength to mechanical damage, it is not resistant to solar ultraviolet radiation. In addition, another sheet with such a coating is expensive.

The most affordable matte polyester . It is applied with a thicker layer than the “glossy” analogue, therefore it is sufficiently resistant to ultraviolet and mechanical damage.

Other types of polymer coatings, such as foam and PVDF , have very high performance properties, but a professional sheet with such a coating costs almost twice as much as with a coating from polyester.

If we talk about the strength to mechanical stress, then powder is in the lead, as a result of which the paint is sintered in a very dense and durable layer. Although the price of such a sheet is one of the highest.

And the last factor of choice is one-sided or double-sided decking. If this question is not necessary for enclosing structures (walls or roofs), and a sheet is chosen that is painted only from the front side, then an “inner” surface is also important for the fence around the house. Although some do not pay attention to it or paint the fence from the inside after its installation.

A double-sided professional sheet has two front surfaces

Preparation

If you make a comparison with building a house, then this stage similar to the design of the project.

First, on the site plan they make a markup - they determine where and how the fence will pass, choose the installation location of the gate and the gate. If the plot goes on two streets, then there may be two gates, and in case of friendly relations with neighbors, the number of wickets increases.

Then calculate the number of supports . The width of the span is chosen not less than two and not more than three meters, and the optimum is 2. 5 m. But it is impossible to achieve exact dimensions, therefore, the principle of proportionality is used so that the distance between the pillars is approximately the same.

Based on the height of the fence, the features of the relief and the ground (and it can differ even in a small area), determine the method of installation of the columns and the size of the underground part.

Calculate the amount of materials : profiles for supports and crossbars, profiled sheet and fasteners.

For reference. The number of profiled sheets depends on the attachment features. It is possible to mount sheets overlapped with continuous flooring (without gaps) or from pillar to pillar. And in both cases, it is necessary to take into account the overlapping of neighboring sheets, pruning when fitting in the corners, near the gate and gate.

A fence divided by columns into sections requires a different approach than a solid fence from angle to angle

Installation steps

Mounting an iron fence from a profile differs only in the way of mounting the supports.

If the pillars are installed without concreting, then first they need to be drilled holes in the ground with a diameter less than the cross section of the pipe or the underground part of the support when it is collapsible. Then, observing the vertical level, poles are driven into or threaded into these holes.

Installation of screw piles using technology significantly speeds up the installation of the fence.

drill holes with a cross-sectional area larger than the pipe. The size depends on the bearing properties of the soil and the loads that the fence exerts on it. For loose soils, formwork is made (for example, from an asbestos-cement pipe), for dense soils - concrete is poured directly into the hole.

The arrangement of the combined base type takes place in several stages:

-

digging a trench;

-

drilling or digging holes for pillars;

-

mount the formwork and the reinforcing frame;

-

install the pillars;

-

pour concrete.

After installation of the pillars (and the ripening of the concrete) mount the cross member using welding or mounting on the screws.

Then the entire support structure is cleaned of dirt, primed and painted. Then proceed to the installation of professional sheet.

Clearly all the stages of editing are shown in the video:

It might be interesting! In article on the following link read about the blocks for the fence.

Conclusion

Despite its apparent simplicity, professionals should be involved in designing and installing a fence. When self-assembly can not take into account all the nuances. Especially if the site is large and the nature of the soil is heterogeneous. Not to mention such moments as the installation of supports for the gate and gate.