Today we will tell in this article about such a very necessary structure, like a metal garage. We will understand the criteria for choosing how to install and assemble it, how the garage is being covered and insulated. Understand the information received - you will understand what, how and why the masters do, who have been entrusted with the construction of this structure and will be “in the subject” when discussing the details.

Selection criteria

To begin with, there is quite a large market the number of manufacturers that offer frame garages of metal of different sizes and shapes. Products are fully equipped with everything necessary. They must be accompanied by instructions on which it is easy to assemble a garage.

It is possible to assemble this building in one day, if its construction is in fact qualitatively made. And the parts fit together exactly. In addition, manufacturers today offer a custom garage manufacturing service. That is, you give them the dimensions from the site where the construction of the garage is planned, and the manufacturer will precisely manufacture the metal construction for these dimensions. But these garages have a significant drawback - the high price is almost exactly the same as that of a car that is planned to be installed in this building. Today, the cheapest garage is in the range of 70000-80000 rubles.

You can use another option to become the owner of a metal-frame garage. Buy ready, only used. Advertisements in newspapers, on Internet boards a huge amount. Here and the price is two to three times less, but we must realize that in addition to the acceptable cost, other "surprises" can wait for the buyer. For example:

-

A collapsible metal garage without a place is for sale, that is, there is a steel structure, but there is no permission to establish it. In addition, the buyer himself still have to transport it, and in some cases disassemble, and certainly assemble. The hardest part is disassembly. For a long time of operation, the fasteners became rusty, and it would not be so easy to unscrew, for example, the bolts.

-

The garage stays outdoors for a long time, and metal and its fatigue are observed during operation. It is not only rust. This is the deformation of assemblies and parts, so you have to put a lot of effort into docking them exactly according to the scheme.

-

The most annoying third purchase option is fraud . That is, here it is a garage, take it and transport it, only pay in advance. And then it turns out that the seller has nothing to do with this garage, that is, he does not own it. And it may be that the seller with the owner in one fraudulent bundle.

And the last option to become the owner of the iron garage is to purchase the necessary material invite the craftsmen who make it themselves. Here the benefit is clear, because you can find materials at a reasonable price on the market, agree with the masters on payment for their services, and fully control the manufacturing and installation process.

What you need to pay attention to when choosing a used metal garage, see the video:

On our site you can find out more popular projects of garages and other small forms for a private house - from construction companies represented at the exhibition "Low-Rise Country".

By the way, about the material. Firstly, after the construction of a summer house or a country house, the rational owner always has metal profile waste that he does not throw out. They can also be used. If the garage is always supervised, then for its construction it is recommended to use cladding materials with low strength characteristics. And this will affect the decrease in the cost of construction. For example, instead of a sheet iron with a thickness of 2-3 mm, use profiled sheeting with a thickness of 0.7-1 mm.

In addition, the owner, together with the invited craftsmen, can himself determine the dimensions of the structure, the type of its roof, the type of insulation material and the inner lining. And all this is tailored to the budget allocated for the construction of a metal garage.

Garage dimensions

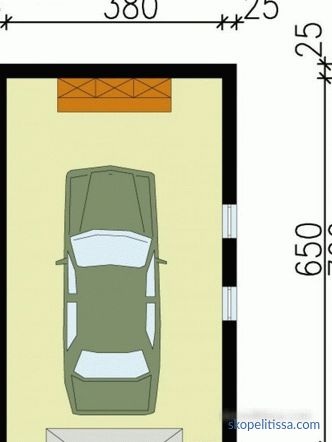

We will not go into philosophical arguments about the huge variety of garage dimensions. Simply denote the minimum and most convenient for one car. So, the length is 6 m, the width is 4 m, the height of the gate is 1.8-2.0 m, although the latter parameter depends on the height of the owner. But less than 1.8 m is not recommended.

Now the shape of the roof. There are two options: single or gable. The first is cheaper because it consumes less material.

Manufacturing and assembly technology of a metal garage

Let's start not with manufacturing, and with the preparation of the base. We will not consider in the article the garage under which the basement is being constructed or a viewing pit is made in the floor. We are interested in the garage itself of metal structures, so the slab foundation is used as the base. Here is the technology of its pouring:

-

in size they dig out a ditch 30 cm deep;

-

fall into it a layer of sand and rubble to the brim;

-

set around the perimeter formwork of boards 100 mm wide;

-

laid on supports a grid made of steel reinforcement with a diameter of 10-12 mm, cell sizes - 20x20 cm;

-

poured concrete solution to the edges of the formwork;

-

last dismantle after 7 days;

-

you can load the foundation after 28 days .

On our site you can find contacts of construction companies that offer the service design and construction of garages and other small forms for a turnkey private house. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

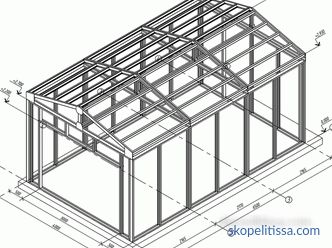

Assembling the frame

While the foundation is drying, they begin to make the frame of the garage. It is collected either from a steel corner, or from a profile pipe, or from galvanized profiles, on which drywall is mounted. The last option is used only if a professional flooring is used as a plating. We will talk about the traditional frame construction from the corner, for which you will have to purchase a 40x40 or 50x50 mm profile, which will be installed on the main components: the lower and upper trim, corner posts. A 32x32 mm corner will be needed for the construction of the roof and the installation of intermediate posts.

The assembly sequence of the metal frame in the video:

And so, our garage is 4x6 m, so cut a corner of 50x50 mm for these dimensions. Four sections of 6 m, four on 4 m. Then four racks of 2 m. Of these elements collect the box right on the slab foundation.

First of all, a rectangle 6x4 m is assembled on the plane. The joints are welded together by electric welding. We will make a reservation that we will tell about how production of metal garages of nonseparable type is made.

Then the racks, cut to 2 m, are installed in the corners. They are pre-set vertically. Attach electric welding to the bottom strapping. Now an important point: the length of 6 m is significant. If you put on two racks corner of the top strapping, then it sags. Therefore, intermediate racks with a pitch of 1 m are also installed in the length of the garage. Only for this you can use a smaller corner: 35x35 or 40x40 mm. The same is done with the side of the building with a length of 4 m.

The elements of the top trim are placed on the installed supports. Welding is performed. Please note that on the installation side of the gate intermediate support stands are not mounted. The corner of 50x50 mm and length of 4 m is quite hard, therefore it will not sag under its weight.

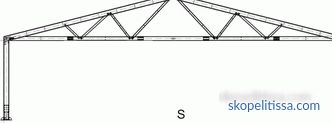

Formation of a roof

The simplest option is a lean-to roof. To do this, on a constructed box above the gate, five segments of the corner are welded vertically with an installation step of 1 m. The minimum length of the segments is 50 cm. They are connected from above with a horizontal piece of a corner.

Then measure the distance from the laid corner to the rear element of the upper casing. It should be more than 6 m. To the size add another 60 cm. This is for the overhangs in front and behind the garage of 30 cm. The size is minimal.

It might be interesting! In the article the following link read about the garage of the sandwich panels.

The rafters of the estimated length of 3 pieces are cut from a corner of 50x50 mm. They are laid in place and welded. Between themselves, they are connected in small segments, spreading along the length every 1-2 meters.

If the roof is a gable, then first collect the farm on the ground in the form of an isosceles triangle. To make it clear what is at stake, look at the photo below. These are difficult to manufacture trusses, because they use jumpers. For a small garage, these elements are optional. Just the corners are welded triangle. It is important to take into account that the edges of the farm building should be at least 20-30 cm on each side. If the roof will be covered with sheets of steel thickness of 2-3 mm, then the overhangs form them. Then the farm is made strictly according to the size of the garage, as shown in the photo.

So, if the trusses are ready, they are installed on the frame box, welding to the top elements strapping. By the way, the optimum mounting step is 1 m. That is, they must rest on the vertical support posts of the frame construction. It remains only to form the crate. It is made from a corner of 35x35 mm, laying across established farms. Installation step 1 m.

Now it is necessary to give the assembled structure greater rigidity. To do this, cut out of the sheet of steel kerchiefs (isosceles triangles with the length of the leg 20 cm), which are welded at the junction of the vertical supports and elements of the upper and lower straps.

Frame cladding

In order to avoid high costs, it is necessary to select metal sheets exactly for the dimensions of the garage to be assembled. In our case, it is optimal for wall sheets with dimensions of 1x2 m, for roofs of 1x2.5 m.

Sheets are simply placed on racks so that the neighboring ones are joined on supports. Laying is carried out outside the garage, welding from the inside. First sheathe the walls, then the roof. Welding is carried out spotwise with a seam length of up to 5 cm.

It can be interesting! In the article on the following link read about the arrangement of the garage.

Manufacturing and installation of gates

They are assembled separately from the general structure. Usually it is a bivalve model consisting of two identical rectangular products. For the manufacture of used all the same corner 50x50 mm. For our garage will have to prepare eight segments of a length of 2 m. They are collected in two squares. Two more pieces are needed to create structural rigidity. They are welded one at a time in each flap in the vertical direction.

-

Then, trimming of the gate with iron sheets, welding them to the corners.

-

It remains only to hang the gate. For this you have to buy four loops.

-

Their upper parts (with a cavity inside) welds to the door leaves.

-

Then the gates themselves raise and put to the garage, exposing it vertically and so that the doors close tightly, but there is a small gap between them. If there is a need, then small supplies are laid under the sash.

-

Insert the lower parts of the loops into the upper parts and make marks on the corner posts where they need to be welded. Experienced masters do it right there without any markup.

-

It remains only to weld to the gate hinges under a padlock or install an internal one, and also attach a handle.

Insulating the garage

Should you insulate the garage from metal or not, everyone decides for himself. If such a decision is made, then here is the easiest and cheapest way. This will require wooden slats with a section of 50x50 mm, foam polystyrene plates 50 mm thick and screws on the wood.

The sequence of the thermal insulation process is as follows:

-

In the corners (racks) there are holes in the shelves that look inside the garage. Step - 50 cm.

-

They are inserted into the corners of the rail , which are fastened with screws through the holes.

-

Between the slats fit polystyrene foam plates glued to metal and wood with special mounting sealant. This is a foam that does not expand in air. The main thing is not to leave gaps between the plates.

-

They also do the same with insulation of the roof and gate.

-

After which the walls, gates and ceiling are clad with panel, panel or sheet material, for example, clapboard, plastic panels, siding, drywall, plywood and so on.

So, the garage is assembled and insulated, and also trimmed from the inside.

It might be interesting! In the article the following link read about house for 6 hours - modular technology MADI.

Conclusion on the topic

A folding metal garage is assembled using exactly the same technology. Only instead of welding using bolts. For durability and reliability, it is not inferior to the welded. Its big plus is the ability to disassemble and move to another place at any time. For all other parameters, they are the same.