The article will talk about what a heater is an isover, how it is produced, what technical characteristics it has, what disadvantages the products of the French concern "Saint-Gobain" have, what types of material presented are most popular in our domestic the market. Photo and video will reveal the nuances of mounting plates and rolls.

What is the isover

Isover is a material used for warming flat surfaces. It is produced by the French company "Saint-Gobain". The name of the insulation comes from two French words "isolation" - isolation and "verre" - wall. It explains what it is made of. In the domestic market are two forms of French insulation. There are plates and rolls. They are molded with fiberglass and basalt wool. Each version has its own specifications. They define the scope of use.

The basis of the material is fiberglass and basalt wool fibers. In the manufacture of slabs or rolls, recycled soda, limestone and sand are added. The use of recycled materials allows you to reduce the cost of the finished product, so the French insulation has a very affordable price.

The technology of making isover is extremely simple:

-

Listed components recycled materials mixed with each other, added to them other minerals , the mixture heated to 1300С and is converted into a plastic mass , similar to liquid glass .

-

It is poured into the tank . In its walls there are microscopic holes .

-

The capacity unwinds like a drum and rotates at high speed . Centrifugal force squeezes the loaded substance through microscopic holes. In this way the thinnest threads are formed.

-

The threads are mixed with a special adhesive compound . Forming a sticky mass.

-

It is sent to the oven-dryer .

-

There the workpiece passes through the rollers . With the help of they form a layer .

-

At the finishing stage, it is cut into the required dimensions . The maximum possible dimensions are 610x1170 mm, the thickness of the plate can vary from 5 to 10 cm.

Technical characteristics

The material obtained by the method described above has unique properties. The layers have high elasticity, low thermal conductivity (0.041), low weight. For heaters, these characteristics are very important. Provided proper installation, technical specifications do not change with time, which ensures maximum heat saving throughout the operation of a residential or industrial building.

air bubbles remain between the fibers. They prevent the penetration of sound. Therefore, using izover for insulation, it is possible to significantly improve the sound insulation of a building. The manufacturer recommends using such material where it is necessary to increase sound insulation without increasing the load on existing surfaces.

Plates can additionally be treated with water repellents. They make the surface of the insulation waterproof. When burning, isover does not contribute to the spread of fire, the material has a low smoke-forming ability.

Note! Izover is ideally suited for warming log structures, frame or panel houses.

When packing, mats are pressed. As a result, their volume decreases by 60%. This greatly facilitates the transportation of insulation. After unpacking, the mats easily regain their shape. They can be used for exterior and interior decoration. During operation, hazardous chemical elements are not released from the surface of the isover. In its manufacture no formaldehyde or resin is used. Therefore, the described material belongs to the class of environmentally friendly.

Insulation, which comes in the form of rolls, is represented by two varieties. On sale there are single-layer and two-layer rolls. They are used to warm the floor or ceiling. The maximum possible roll length is 14 m, the standard width is 120 cm.

On our site you can familiarize yourself with the most popular projects of houses from the best construction companies with an impeccable reputation in the market. You can choose a house without finishing or from any modern building material. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Existing types and scope of application

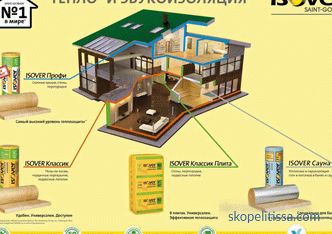

The French concern "Saint-Gobain" produces various types of insulation.In the Russian market, nine types of isover are most popular:

-

Thermal insulation isover KL 34 - non-pressed plates, which have a very wide scope of application, are used for insulating any vertical and horizontal surfaces . wooden crate is constructed for installation. Inside the plates are inserted without additional fastening.

-

Isover KL 37 - pressed plates laid in packaging . floors between two adjacent floors , internal walls and roof slopes are used for insulation.

Important! When installing the slab, press firmly against each other.

-

Isover CT 37 - roll insulation. It is used for insulating horizontal surfaces. This type of release can also fit on the walls, but only if it is necessary to insulate internal partitions .

-

Isover КТ 40 - two-layer rolls used for warming the ceiling and the floor .

-

Isover " STYROFOAM " 300 A material, polystyrene foam was added to the structure of which. These are plates of increased rigidity . They are attached to the surface using plastic dowels or special adhesives, based on bitumen mastics.

-

Isover " VENTITERM " - plates treated with an additional water repellent . This is a new product, it is still conquering the market. Its scope of application is insulation of facades , carried out with the help of installation of single-layer or double-layer systems.

-

Insulation isover "pitched roof" - material intended for warming roofs , to improve the sound insulation of rooms. Available in the form of slabs with dimensions of 610x11700 mm, 10 cm thick. The material has high elasticity and elasticity, therefore

On our website you can find contacts of construction companies that offer the service of roof repair, installation of windows and doors, and house insulation. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

-

Isover "soundproofing" - material intended for sound insulation of rooms. It is produced in the form of plates with a thickness of 5 cm, can be used in any climatic zones. With it, you can improve the sound insulation of the roof, internal and external walls.

-

Isover "Ventfasad" are double-layer plates intended for insulation of ventilated facades .

The choice of French insulation has its drawbacks. They must be taken into account when buying insulation. Since it contains fiberglass, it is possible to work with the material only with the use of protective equipment. You should wear gloves on your hands, pants and a jacket with long sleeves, glasses on your eyes, a gauze bandage on your face. If you ignore this safety precaution, any contact with mats or rolls will cause severe skin irritation.

During operation, dust may be released from the isover. In its composition will necessarily be present fiberglass particles. Their entry into the human body can provoke the development of diseases. Therefore, when carrying out internal warming, it is important to close the material before laying the topcoat (clapboard, drywall) with a vapor barrier film.

Izover cannot boast of high mechanical strength, he is not able to bear the load, so improper installation often leads to deformation of the finish. Such defects are often used by insects and mice for colonization.

If the plates were not additionally treated with water repellents, they will absorb moisture well. It lasts for a long time in the inner layers, making the material properties change.

Note! With an increase in the moisture content of fiberglass by 1%, the insulation decreases by 10%.

This may be interesting! In the article on the following link read about facade thermopanels with insulation for exterior home decoration: types and prices.

Technology of laying isover from inside walls

For laying of mats it is necessary to construct a crate. This can be done with the help of wooden beams or metal profiles used for laying drywall. The pitch of the batten should be about a centimeter wider than the insulation width.The plates due to the high elasticity are easily embedded in the space between the two guides and very tight to the surface.

From above, the insulation must be covered with a vapor barrier. The film is laid overlapping, the joints are additionally sealed with a special vapor barrier tape. From above such design can be sewn up by gypsum plasterboard or immediately to mount lining.

The video shows the technology of wall insulation of a frame house with an isover:

Isover mounting technology from the front of the building

A crate with step per centimeter is the width of the insulation. The plates are placed inside, the counter-grill is mounted on top. It should provide an air gap. It is attached to the waterproof and windproof membrane. And already on it the finishing decorative furnish (siding or lining) fastens.

It may be interesting! In the article on the following link read about suburban real estate as an investment: is there a benefit and does it make sense to invest savings.

Technique of sound insulation using the isover

Sound insulation of the bottom surfaces is based on the "floating floor" technology. It helps reduce indoor noise by 50%. It is so called because the materials used for finishing do not come into close contact with the side walls. Therefore, no noise waves are transmitted to them.

To construct such a structure, a vapor barrier is spread onto a reinforced concrete base, then an isover is placed on it. Above spreading waterproofing material. From above such a pie can be poured with a concrete screed or covered with plaster sheets. Even before work starts around the perimeter of the floor, it is necessary to glue a damper tape to the walls. It will provide the formation of a technological gap that will not allow noise to move through the ceilings. The width of the tape should exceed the thickness of the tie by 2-3 cm.

Video shows the technology of floor insulation with Izover thermal insulating material:

This may be interesting! In the article on the following link read about a house in Cupertino - with a garage on the roof, an office and a seating area “sunk” into the floor.

Summary on the topic

The products of the French concern "Saint-Gobain" have a wide scope of application. It has unique technical characteristics, boasts durability, versatility and practicality. Materials are easy to install, they are convenient for transportation, they can be used for any geometry, the price for packaging starts from 300 rubles. Packing the most expensive variety of material costs around 2500 rubles.

Rate this article, we tried for you