Building a house for shrinkage from a turnkey profiled beam has long been separated into a separate service from construction companies, showing its practicality and efficiency. The popularity of such a decision is primarily due to the ability to clearly comply with the technology and the sequence of work and divide the costs into two parts - first the creation of the box at home, and after 6 - 12 months - finishing.

Main factors affecting shrinkage

When ordering a house from turnkey timber, you need to consider that it will take some time during which there will be some changes in the size of the building. This is caused by the natural processes of drying wood and shrinkage. The main factors affecting this are:

-

Humidity of the profiled bar;

-

The time of year when wood harvesting was carried out;

-

What method of drying was used;

-

The season in which construction work was carried out;

-

The climatic conditions in a particular region;

-

The quality of work performed, including waterproofing of the roof, foundation, pavement.

If a profiled bar of natural humidity is used, the time for complete shrinkage takes 3 years on average. Therefore, more and more often, the choice is stopped on the house from a turnkey bar under shrinkage, from the material that has been subjected to chamber drying. In this case, its humidity will be much less - no more than 18%, and only 1 year will be required for shrinkage, and its value will not exceed 3 cm. It is important that such a blockhouse stand all seasons and adapt.

The advantages of houses for shrinkage

A log house under shrinkage has a number of advantages when compared with buildings made of other materials:

-

The speed of construction.

-

Drying of wood occurs naturally. This has a positive effect on the performance of the entire building.

-

The deformation of floors, walls, partitions occurs correctly, without the formation of gaps and without leaving the plane.

-

Environmental friendliness;

-

In the house, optimum temperature and humidity are created and maintained from a profiled bar.

-

Relatively low cost.

For a log house for shrinkage, the price may not be cheaper than during the turnkey construction, but it will have much less pressure on the family budget, since the construction of the house will be divided into two stages with the gap between them in a year and a half.

It is also important to pay attention to the fact that all elements of such a log house are manufactured in factory conditions. The construction of the house is carried out by highly qualified specialists, using professional equipment and tools. All this guarantees high quality of work and long service life at home.

On our site you can familiarize yourself with the most popular projects of houses made of profiled timber from construction companies presented at the exhibition "Low-Rise Country".

What is included in the standard package

The construction of a log house from a profiled bar is assembled in just a few weeks. For this, a bar with a cross section of 200 * 200 or 150 * 150 (external walls), 100 * 100 (internal partitions and walls) is usually used; for floor blades, a bar with a cross section of 150 * 150 is used, with a pitch of 600-800 mm.

If a second floor is provided for in the project, then for interior walls, partitions, and lags, a profiled beam of the same section is used, and for a 40X100 board frame. Draft floor made of boards 20x100 or 25x100. Insulation - flax fiber or jute. Rough roof - ruberoid.

Basic configuration of a log house for shrinkage:

-

external walls;

-

internal walls, partitions;

-

lags;

-

rough floor;

-

gables;

-

truss system;

-

door and window openings;

-

draft roof (can be straight or broken);

-

lathing;

-

power elements (lags);

-

insulation;

-

draft ladder (if it is a project of a two-story house);

-

fasteners (wooden pins, nails).

Additionally, you can order the arrangement of the foundation under the frame of a profiled bar for shrinkage. Most often for such houses use a columnar, tape, pile-screw, tile or column-support foundation.

How long shrinkage lasts

For houses built from profiled timber with moisture from 30%, time for shrinkage is 3 years, and for houses from timber with moisture up to 18% - only 12 months. Therefore, it is the second option that is more preferable, especially since the amount of deformation is much less - 3 cm versus 10 cm (in the first case).

What determines the price

The price of a log house for shrinkage from a profiled bar depends on such factors:

-

The complexity of the project.

-

When assembling.

-

Type of wood. From pine, spruce will be cheaper than from aspen and larch.

-

Distance from the city.

-

The house will be designed for year-round or seasonal only.

The average cost of 1 m² of this log house will cost from 10 thousand rubles. You can also order a number of additional services. Among the most popular, you can highlight the assembly on the spring node, the construction of the foundation, increasing the thickness of the log, the arrangement of an additional crown and some others.

On our site you can find contacts of construction companies that offer the service of building houses from a profiled bar. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Several examples of the most popular projects, photo and video

-

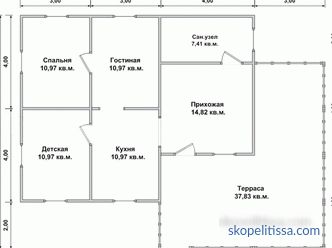

Economy project - 4 * 6 with an attic

This is one of the most common and popular projects of houses for temporary residence. Budget option that is perfect for a small suburban area. The main advantages of the project are compactness, speed of assembly (1-3 weeks), low cost and environmental friendliness.

-

Two-storey house 6 * 8

A typical house project that is equally well suited as a small private house , within the city, and for a country cottage.

It can be interesting! In the article on the following link read about the insulation of a log house outside.

-

Two-storey log house from timber 7 * 9

Despite its compactness, the living area is 63 m² (7Х9), and the total is 108 m² . The project compares favorably with the successful zoning of the interior and a rich bundle. And this is despite the fact that the construction of the house for this project requires only 10 days. The cottage is quite suitable for a large family.

-

House 10 * 13 in American style

In the first place here is simplicity and comfort. The house occupies a rather impressive area - 130 m 2 , of which 100 m 2 living rooms are 100m². One floor and the lack of stairs make living in such a house as convenient and comfortable for people of all ages.

A few more projects of houses from a profiled bar look in the video:

It can be interesting! In the article on the following link read about home from the minibus.

Conclusion

The growing popularity of such log cabins is also largely due to the fact that they harmoniously fit into almost any surrounding landscape, are environmentally friendly and are ideal for living, both seasonal and year-round. You can see the different types of cottages "live", compare their characteristics, consult with experts and choose the most suitable timber house for shrinkage - without finishing and cheap, you can at the "Low-Rise Country" exhibition.

Rate this article, we tried for you