Warming a garage is a process that worries many owners of this small building today. Everyone began to realize that in a warm room the car lasts much longer. Therefore, in this article we will talk about the ways of warming, than to warm the garage from the inside and outside, to what moments of the warming process we should pay attention first of all.

How best to insulate: outside or from inside

For all construction canons the best option - insulation outside. The fact is that the boundary between the insulating material and the cladding is the area where condensate forms. And if you do the insulation from the inside, then this area falls between the insulation and the walls of the garage. At the same time, the latter freeze through in winter completely (through), which adversely affects the building material itself. Plus, condensate, which reduces the performance of any building material.

This is the first reason. The second is the opportunity not to reduce the useful space in the garage. The heater laid on the walls takes up some space. This will have to add the thickness of the skin. That is, on each side of the walls about the reduction will occur by 3-5 cm.

The third reason makes it possible not to pay attention to the environmental friendliness of the insulating material. It will be located on the outside, the street side, which means that if the insulation releases substances harmful to humans, they will immediately evaporate. At the same time, such materials are much cheaper than environmentally friendly ones.

But it is not always possible to warm the walls of the garage outside. If for some reason it is impossible to do, then all the insulation work is transferred inside.

Overview of the market for thermal insulation materials

Before proceeding to the process of insulating a garage structure itself, let us tell you about heat insulators. About those that are used today for this purpose. There is a fairly large amount of building materials of this type, which builders today use. Here there are traditional materials, there are recently appeared, but already gained popularity.

Mineral wool

This insulation has been used in construction for a long time. At the very beginning of its appearance, it was a roll-type material. Today, it is still produced in this design, but the modern form of mineral wool is a slab. They are called mineral wool plates.

It should be noted that a rather wide list of materials is used as a raw material in mineral wool plates. But basalt-based insulation is very popular. This heat-insulating material is presented on the market by plates of different density and thickness. This makes it easier to choose the desired characteristics.

The only drawback of mineral wool is hygroscopicity. That is, this material is well absorbs moisture, while losing its thermal performance. To prevent this from happening, the heat-insulating layer is closed on both sides with waterproofing films. Today, manufacturers offer moisture-proof slabs of mineral wool, in which the hygroscopicity is reduced to the maximum. This makes it possible to abandon waterproofing.

It will not tell about all the technical characteristics of mineral wool. We denote the most significant, according to which it is necessary to choose insulation. This is the thermal conductivity of the material.

Note! Thermal conductivity is the property of a material or body to transfer heat. The lower this parameter, the better in terms of insulation.

So, in mineral wool, this characteristic is 0.035-0.04 W / m K.

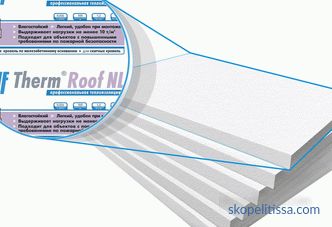

Polystyrene foam plates

Many people call this material foam, which is fundamentally wrong, although Both materials are part of the group of foamed plastics made of polystyrene. Just foam is a material originally created for packaging. It has a low density and low thermal insulation quality. What can not be said about polystyrene foam, which was originally designed as a thermal insulation material.

On our site you can familiarize yourself with the most popular sites in the Moscow region for the construction of a country house . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

This foamed insulation has serious advantages:

-

thermal conductivity - 0.028-0.034 W / m K;

-

the extruded version does not absorb moisture ;

-

passes air through itself;

-

strength - 1 kg / cm²;

-

is inert to many chemicals;

-

on insulation surfaces do not live mold and fungi;

-

it is a good sound insulator ;

-

service life - 30 years.

But polystyrene foam plates have their disadvantages. And the most important of them is fire hazard. Insulation burns well and supports combustion, while emitting acrid smoke. Today, manufacturers are trying to change the situation with this indicator. Fire-resistant plates have already appeared on the market, but there are not so many of them.

And one more point to which it is necessary to pay attention, choosing expanded polystyrene as a heater. This is a brand of material. Optimal for the garage option - PSB-S-35 (40) - self-extinguishing, with a density of 40 kg / m³. The thickness of the plates should not be less than 50 mm.

Polyurethane foam

This is a two-component material, the ingredients of which are before applying are mixed up. According to its physical state, it is a foamed semi-liquid mass, which solidifies in air, forming a hydrophobic layer on the heat-insulated surface. That is, not afraid of moisture.

Polyurethane foam requires special equipment. It is applied under pressure from a hose with a nozzle. High adhesion characteristics of the material enable it to adhere to any surfaces that are pre-cleaned of dirt and rust. In this mixture fills all the cracks, gaps and holes.

This is a non-combustible insulation. Service life - 50 years. Thermal conductivity - 0,019-0,028 W / m K. moisture absorption minimum - 1.2%.

On our site you can find contacts of construction companies that offer construction services of small architectural forms . Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Warm plaster

This plaster solution got its name because manufacturers add particles of heat-insulating material to it. These can be expanded polystyrene granules, so-called crumb, vermiculite (foamed stone of volcanic origin), sawdust, and other ingredients.

In fact, such a plaster mixture possesses higher thermal insulation characteristics than ordinary plaster. But in order to achieve a good effect, the material must be applied in a sufficiently thick layer. It is used for insulation of the garage from the inside, and for insulation outside. It is clear if the garage is built from bricks, blocks or concrete slabs. For metal construction, this option is unacceptable.

So, we looked at the main heat-insulating materials that are most often used today when conducting insulation garage built. Of course, this is not the whole list of proposed options. Just use these more often.

Most often, many consumers are looking for something to insulate a garage from the inside inexpensively. The table gives a comparison of prices for the described heaters.

| Heat insulation | Mineral wool plates | Polystyrene foam plates | Polyurethane | Warm plaster |

| Price | 13-20 rub. for 1 m² | 15-50 rubles. for 1 m² | 1200-1500 rub. for 1 m² | 350-750 rub. for 1 m² |

The price fork for each material is quite wide. This is explained by the fact that the basis of pricing is the thickness of the insulation, its density. The table shows that the most inexpensive option is mineral wool and polystyrene foam plates.

It may be interesting! In the article on the following link read about which one is better to buy a house on wheels - features of motor homes, their varieties and prices .

Insulation Technologies

Having understood the question of how to insulate a garage, we proceed directly to the process itself. Let's start with external insulation. The easiest option is plastering. Everything is quite simple here. Warm plaster is applied to the outer surfaces of the garage walls using standard technology. That is, they throw a trowel on the surface and align it with the rule according to the established beacons.

There is a version of mechanized plaster. For this purpose, special stations are used, in which a plaster mixture is prepared and from it is immediately carried out drawing on the walls under pressure.In this way, we can carry out insulation from the inside of the room.

In order not to go into the details of the technological process, we suggest watching the video, which tells how to properly apply warm plaster on the walls in two ways:

Expanded polystyrene plates for external insulation

If the garage is built of brick or blocks, the expanded polystyrene plates can simply be fixed to wall surfaces, stacking them tightly to each other. There are two ways of fastening:

-

on mushroom-shaped screws or more precisely on dowel-nails for insulating materials;

-

on the adhesive composition .

Usually, the first one is used, because glue for expanded polystyrene is an expensive thing. It is sold in cans. Content is applied on the back side of the plate in the corners and in the middle. And then just pressed to the wall.

As for the self-tapping screws, these are special fasteners made of plastic, consisting of two parts: a dowel and a nail. Under the first through the insulation in the wall make a hole where the plug is inserted. In this case, his wide cap will hold the insulating plate. After that, the second part is hammered into it, which spreads the first.

Usually, two fasteners are used for each plate. When laying insulation it is very important to ensure that there are no gaps and cracks between its elements. It is best to use plates with groove-tongue joints for this. If ordinary plates with smooth edges are used, then when the gaps between them are formed, the latter are filled with special foam. It is similar to the assembly, only the air does not expand in volume.

It might be interesting! In the article next link read about projects of garages with attic: advantages and features, examples in the photo .

An interesting fact is that the wall insulated with polystyrene foam can be plastered. To do this, plaster synthetic mesh is laid on it and the plaster layer itself is applied. You can put a heater under the ventilated facade, for which you have to first assemble the frame, lay insulation on it, and install finishing material from above. In the photo above, this option of finishing and warming the outer walls of the garage is shown.

Mineral wool for outdoor insulation

For mineral wool, it is better to build a ventilated facade. That is, the frame is assembled on the walls of a garage either from wooden slats or from galvanized metal profiles used for installation of plasterboard sheets. On the street it is better to use a moisture resistant option. But even with its use, it is recommended to close the heat-insulating layer with a waterproofing membrane.

1> direct suspensions are mounted on the wall, on which the elements of the batten will be mounted. The distance between them vertically and horizontally 50-60 cm.

Installation of insulation . It doesn't matter how wide this material is. It can easily be installed directly on the mounted hangers, making holes with a knife. The main thing is to install mineral wool plates tightly to each other.

Mounting of the batten components .

Laying waterproofing in the form of horizontal membrane strips, which are attached to the frame and spread out overlap relative to each other. Joints necessarily fasten self-adhesive tape.

Mounting of the plating: siding, decorative slabs and more.

There is a frameless version of the insulation of the walls of the garage. To do this, mineral wool or polystyrene plates are attached to the walls with dowel-nails. And then sheathed with bricks. Under the latter will have to pour a narrow foundation.

It might be interesting! In the article at the following link read about stages of the formation of a concrete floor in the garage: technologies and materials + photos and video .

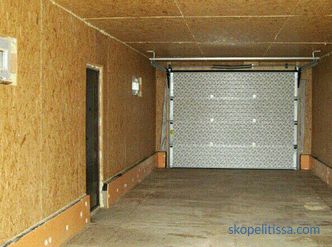

Internal insulation of a garage

In principle, everything described above can be transferred inside a garage building. These technologies are also applicable here. The only thing was not marked polyurethane foam. The least problem with him. If the garage is brick or block, then a crate is installed on the walls, on which the finishing will be carried out. It is better to use wooden blocks, which are attached to the walls with screws and dowels.

Foam is applied with a layer equal to the thickness of the frame elements. After solidification on the treated surfaces, a seamless heat-insulating layer with a sufficiently high strength is formed.

By the way, in this way it is convenient and efficient to warm garages assembled from metal profiles and sheet metal.

Warming from the inside of the metal garage

By itself this building represents a frame made of steel or the profile pipe sheathed outside by metal sheets or a professional flooring. That is, it turns out that the frame of the garage is located inside. And it automatically becomes a frame for decoration. So between the trim and the outer skin you can lay the insulating layer.

If polystyrene foam plates are used, they are attached to the steel surface with an adhesive composition. The main requirement for installation is a tight fit of the plates to each other.

If mineral wool is used, they are not glued to metal. To do this, select the plate width so that they entered between the elements of the frame in the tension. If the distance between the elements of the lathing is greater than the maximum width of the insulation, then in the gap between the frame of the garage, wooden bars are installed, reducing the distance.

And as for polyurethane foam. This is the best option for warming the inside of the garage.

The video shows how to insulate the inside of the garage with polyurethane foam:

It might be interesting! In the article at the following link read about a garage and a bath under one roof - features and examples of projects .

Warming the floor and ceiling in the garage

With the floor is the easiest. This is a thick concrete screed, under which you just need to lay insulation. More often for this use claydite. They do it this way:

-

At the site where the garage is installed they dig out a ditch with a depth of 50 cm.

-

rubble is covered with a layer of 15 cm.

-

Then sand with a layer of 15 cm with ramming.

-

Cover with roofing paper in two perpendicular layers.

-

Claydite is filled up.

-

Another waterproofing layer .

-

Lay the reinforcing bars made of steel reinforcement.

-

Pour concrete .

It is possible not to fall asleep on claydite, but instead of concrete to use claydite-concrete solution. You can fill in perlite instead of expanded clay, or lay polystyrene plates.

As for the insulation of the ceiling, everything will depend on what this building element of the garage is designs.

-

If this is a concrete floor slab , then it is better to assemble the suspension structure into which the insulation is laid. You can apply warm plaster.

-

If it is a metal roof , then it is optimal to process it with polyurethane foam.

-

Since the roof of the metal garage is assembled, like the walls, in the form of a frame lined with iron on the outside, you can put plate insulation between the elements of the sheathing. The technology is the same as on the walls.

The video shows one of the options for insulating a garage ceiling:

It might be interesting! In the article on the following link, read about a birdhouse in a Canadian forest .

Conclusion on the topic

Thermal insulation of the garage is the minimum cost, even if you use expensive polyurethane foam. The main task is to carry out the above processes correctly, taking into account the construction of the building and the characteristics of insulation. But for this it is recommended to turn to professionals who will perform all the work quickly and efficiently.