For finishing the house and complete the appearance of the foundation use a variety of options for finishing the facade. The article describes the types of basement stone and the rules for its installation.

The advantages of finishing from the basement stone

The decoration of the basement of a private house with an artificial stone has its advantages and limitations. The huge advantages include:

-

resistance to high humidity and even to flooding;

-

resistance to temperature differences ;

-

as massively as it looked, has a small weight , which is important when calculating the load on the foundation;

-

cheapness material;

-

long service life;

-

resistant to burning, non-toxic;

-

a wide choice of stone designs;

-

lightness when mounted.

If we talk about the shortcomings, they all are the result of a violation of the technology of the process of manufacturing and mounting the base.

Type of artificial stone

Materials for cladding has a rich assortment. Decorative stone for finishing the basement of the house is different not only in color and shape, but also in the materials from which it is made.

Flexible base stone

Consists of two layers of polymeric material. It is available in roll and block tile form. This type of lining has the following characteristics:

-

due to its flexibility, it is possible to decorate the facades with a complex texture ;

-

very lightweight ;

-

resistant to high temperatures, fireproof;

-

vapor permeable ;

-

moisture resistant ;

-

resistant to temperature differences;

-

large life operation;

-

economical when mounted;

-

lightweight when mounted.

This material can be easily mounted to almost any type of facade, it is conveniently cut with scissors, individual elements can be cut from the general web to accentuate the decoration fragments. It should be noted that the front side of the material is covered with a protective film, it is removed only after the completion of installation work.

The disadvantages of this material include a relatively high price.

Polymer-sand stone

Due to the special composition of sand and polymeric materials, this type of material does not differ from a real stone in appearance. Facing the basement of the house with an artificial stone from a polymer-sand mixture has the same characteristics as the flexible facing. The only difference is the lack of flexibility of the material and increased heat capacity. Facing the base of this material can be done on any surface. The tile is mounted on the batten and has tongue-and-groove fastenings between them.

Artificial concrete facing stone

This material was one of the first to appear as an alternative to natural stone. For a long time had a great popularity and is still in demand. Facing stone of concrete has a number of positive characteristics:

-

resistant to fungal formations;

-

resistant to subzero temperatures;

-

long service life with timely care.

This type of stone is made from a mixture of ordinary concrete and plasticizer. Large elements are necessarily reinforced. Such a stone is attached to a special anchor, since due to its large weight, the material on cement-adhesive mixtures will not be held.

Clinker tiles

Clinker stones for facing the basement of the house are made of special types clay by firing in a furnace with a high temperature. This type of material simulates a wide variety of textures, ranging from cuts of stone and ending with brickwork. Most often produced in the form of piece elements and panels with tongue-and-groove fastening system. The brick tile has a number of advantages:

-

resistance to temperature differences ;

-

resistance to high humidity ;

-

high resistance to abrupt climate changes;

-

resistance to fading in the sun ;

-

little exposed to mechanical stress .

The main disadvantage is the price of the material, but due to the long service life this price will justify itself with interest.

On our site you can familiarize yourself with the most most popular suburban areas in the Moscow Region home . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

Decorative layer of concrete "under the stone"

The easiest and most affordable way to decorate the foundation. A thick layer of concrete is applied to the foundation, and then the appropriate relief is applied with special tools. Paint and varnish are applied with a finishing coat for a more attractive look.

It is worth noting that when choosing a house lining with artificial stone, you should consider a number of factors that significantly affect the performance characteristics of a particular type of decorative trim.

Tips for choosing a stone

-

Price . Quality material can not be much cheaper than natural stone. If the price is significantly lower, there is a risk to buy defective or low-quality goods.

-

When choosing a stone on a cement basis, it is worth wondering in what form was cast. Silicone form is best suited for this purpose.

-

Pay attention to the paint . Different colors should have clear boundaries, and the paint is distributed evenly and to the full depth. This will provide you with a beautiful view of the base, even if chipping or potholes are formed during operation.

-

Finishing material should be smooth and solid , chips, holes and gouges should be absent. This indicates gross violations in the manufacture of the material.

-

On the back of the tiles should be applied special grooves for better adhesion with glue.

-

The material in the form of tiles should have clear and even edges .

-

Age of the house and foundation . The older the foundation, the easier the facing material should be. Before installation, thorough foundation research should be carried out. If we are talking about facing new construction, then choose the material based on the type of the foundation and decorative appearance.

Installation steps

In order for the facade to retain its attractiveness for a long time, it is necessary to follow simple rules when finishing with a stone basement.

It may be interesting! In the article on the following link read about materials for cladding the facade of the house .

Installation of the base on the tile adhesive

All installation work should be carried out under certain temperature conditions. It is extremely undesirable to carry out laying of a socle at sub-zero temperatures and at too high values of the thermometer. The optimal range is from +5 to + 25 degrees.

If there is an urgent need to lay the basement at low temperatures, it is necessary to build a protective barrier around the basement of the film. Inside the building the air is heated with a heat gun or heater. This method is quite long and costly, since it is necessary to maintain the temperature until the glue is completely dry. An alternative option may be a special frost-resistant adhesive. But the quality of such masonry may suffer.

At too high temperatures, the glue dries much faster, which can lead to a deterioration in the adhesive properties of the material and shorten the service life.

-

The surface is prepared for work : drops and irregularities of more than 5 mm must be plastered, the wall should be cleaned of dust and dirt. After that, the wall is ground two times.

When laying the finishing material on the brick wall, you should process the brick with a means to prevent salt from being released.

-

The markup and the layout of the stones are made. Pay attention to the corners and the top row. It is best to lay out the stones beforehand on a flat surface in the order in which they will be glued.

-

The tile on the back side of the is cleared of dust .

-

The adhesive mixture is prepared according to the instructions on the package. Mixer is used for thorough mixing.

-

The adhesive mixture is applied to the entire surface of the tiles. Gently stone applied to the wall.

-

Gently remove any glue residue between the seams of the tiles. If the laying implies the presence of seams, then special beacons are installed between the tiles. And after complete drying, the seams are rubbed with a special grout and a narrow trowel.

-

After the laying and drying of the adhesive is completed, the base is treated with a special solution that will protect it from the external environment.

Facing the frame or the "dry" method

-

Wall preparation . To clean the surface from cracks, protrusions and sharp edges clean. To process a concrete or a brick with solution from salt extraction. And wooden walls to process a protective primer.

-

Set to a skeleton from a profile .From the corner of the building to the first attachment, the distance should be at least 10 cm. And the subsequent parts should be fixed at a distance of 40 cm.

-

Material fastened to screws . The bottom row is fixed tightly: one plate is fixed on 4 screws, and all subsequent rows are fixed on 2.

-

Separately install panels in difficult places . Set on top of the ebb.

For several more options for mounting decorative elements, see the following video:

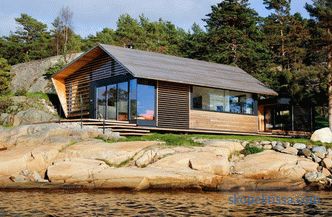

It might be interesting! In the article on the following link read about modern cottage with cedar decoration .

Conclusion

As we see today there are many options for finishing the basement with materials that are no worse than natural stone, and in some cases even better than it. It should be noted that for a long service life it is necessary to carefully select the material, and also to follow all the rules of its installation.

Rate this article, we tried for you