The subject of the article is the mauerlat for a gable roof erected on a house of aerated concrete. We will tell about the importance of the mauerlat in the construction of the roofing structure, about the methods of fastening it to the wall of gas silicate blocks, about the difficulties that can be encountered, about fasteners and so on.

Popularity of aerated concrete houses

Construction of private houses erected from aerated concrete blocks, at the peak of popularity. And even there is a tendency that popularity will not decrease recently. And the reasons for the building material itself, which has a number of undeniable advantages:

-

large block sizes with a small proportion of the material ;

-

a clear geometry , which makes it possible to reduce the fit of the blocks to each other;

-

using a special adhesive composition that is applied thin layer , which reduces the thickness of joints to a minimum;

-

the walls of the gas silicate have a small mass that allows you to reduce the cost of the formation of the foundation;

-

themselves aerated concrete b oki relating to product categories of aerated concrete, has a good thermal characteristics .

But this cellular material has one big drawback - these are the difficulties that builders face when it comes to attaching other structural elements of the building to the porous walls. This is directly related to the power plate, because its location is the upper ends of the walls, to which it should be attached.

As practice shows, classical fastening technologies cannot be used here. Of course, the ideal option is to fill the reinforcing belt in which to install the vertical studs. But many craftsmen try not to make gas-silicate walls heavy with reinforced concrete tape construction, therefore they are looking for ways to do without it. Therefore, we will continue to talk about these methods of attachment and be sure to indicate how justified they are.

About the importance of the mauerlat

Before proceeding to consider ways of attaching the roof to the walls of aerated concrete, I would like to say a few words about the mauerlate itself. To begin with, this is one of the most important details of the construction of the house. Because in its functional load it can be compared with a strip foundation. Only on the mauerlat the roof structure loads.

A load from the roof, I must say, considerable. In this case, they act not vertically, but horizontally, that is, perpendicular to the plane of the walls. The latter, in this case, work on bending, which is very dangerous for vertically located structures. In fact, the roof of the house acts on its own walls destructively.

But this is not all. A truss system consisting of truss legs is a structure that acts on the walls of a building with point loads. And for structures assembled from a piece of wall material, which includes gas silicate blocks, this action is a point of destructive action. So the mauerlat evenly distributes these loads along the entire length of the walls, reducing them at each point separately.

And the third positive quality of the Mauerlat is the simplification of the process of connecting the rafter legs to the walls of the building. It would be difficult to fix each rafter to the wall. It is much easier to do this when two wooden elements are connected to each other. At the same time, a sufficiently large number of fastener options from traditional "deaf" with the use of nails and screws, to movable ones, in which modern fasteners are used, open up.

Usually a beam with a minimum section of 100x100 mm is used as a power plate. But among builders there is a tacit opinion that the height of the timber used should not be less than two thicker trusses. As for the width, the best option is the thickness of the wall on which the mauerlat is mounted, minus 5 cm. That is, the main task is to prevent the mauerlat from exerting natural loads, both from the outside and from the inside.

Since the mauerlat is subjected to quite serious loads, then for him choose a bar of the first grade with a reduced coefficient humidity. Experienced craftsmen recommend using hardwood beams for the Mauerlat. But to find such material today is not easy, so they use pine more often.

If the truss system is made of metal trusses, then instead of wood for a power plate, you can choose a steel profile, usually a channel or an I-beam. In private housing construction metal profiles are rarely used. This is the exception rather than the rule. The preference is still given to wood.

On our site you can familiarize yourself with the most popular projects of aerated concrete and foam concrete block houses from the best construction companies with an impeccable reputation in the market. The site offers a free order calculation of the project. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

About fastening the mauerlat to the walls

If the task is to attach the mauerlat to the wall built of brick, concrete blocks, stone and other durable materials, there are not so many ways to connect, but there are still a few . They are reliable enough, tested by time, so they are easily applied in practice.

For example, one of the most common when laying brick in two or two brickwork or three layers of wire rod with a diameter of 4-6 mm. This twisted steel braid is laid on top of the laid mauerlat, where it is twisted, attracting the beam to the end of the wall. Such a mount is actually reliable. Moreover, such twists are installed every 1-1.5 m. And it is better if they coincide with the installation step of the rafter legs.

It should be noted that it is this version that some masters recommend using in the process of mounting the mauerlat to the wall of gas silicate blocks. For this wire twist must be laid at the level of the blocks, which are located below the upper end of the wall at three or four rows. A waterproofing layer, for example, roofing material, folded in two layers, must be laid under wooden beams. Tightening the fastener is carried out using a crowbar. It is important not to twist here, in order not to create a large point load on the gas block through which the wire structure is passed.

But here another question arises - whether the silicate block actually cuts the wire through the gas silicate block . After all, the wind loads acting on the roof swing the power plate that acts on the fastener, that is, on the twist. Most likely it will. Therefore, this option can be classified as intended or possible. In any case, there is no concrete confirmation that in this way it is possible to connect the roof and the wall of blocks, meaning gas silicate.

On our website you can find contacts of construction companies that offer the service of roof repair, installation of windows and doors, and house insulation. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Fastening with anchors

The metal anchor is a reliable fastener with which you can guarantee a very strong connection. But here, as in the previous case, if we are talking about walls made of brick, blocks or stone. Unfortunately, it should be noted that the load on the walls even from mauerlat large. This is not a furniture cabinet or TV that weigh a little. Anchor with such loads to cope without problems.

The roof structure is a huge load that has a destructive effect on wall materials with low bearing capacity. But still the masters use this option of fastening, but with one reservation - the length of the fastener, in this case the anchor, must be within 300-500 mm. Such fasteners are not cheap, but it can be used to give at least some guarantees on the quality of the final result.

The installation process of the mauerlat is carried out in the following sequence:

-

at the end of the wall, waterproofing material ;

-

are placed on top of timber , as a power element , which is aligned with the vertical surface of the wall;

-

after a certain distance equal to the installation step of the rafter legs, drill a hole ;

-

pushed there anchor , the head of which is twisted to the stop.

The video shows the mounting technology of the wall mount to the wall using anchors:

Chemical anchors

More recently, nobody knew about this mounting technology. Although many masters know how to fix any steel pin with epoxy. Here, the same technology, just instead of epoxy resin with a fixer, use other ready-made compositions.

One method is called capsule or apmul technology. This is a capsule in which adhesive composition is sealed. She is driven into the prepared hole, where the pin is driven from above. The first burst, the glue spreads inside between the walls of the hole and the thread of the stud. After polymerization, and it can take up to 45 minutes, a very strong mount is obtained.

The second option is a two-component composition in cans. The pistol nozzle is put on the last one, with the help of which the composition is fed into the drilled hole.The composition is a polymer mass, quite viscous. Therefore, the anchor will have to be screwed into the filled hole, and not hammered.

It may be interesting! In the article on read the following link about options gable roof and its features.

What can be said about the advantages of chemical anchors:

-

high fastening reliability with long operating life - up to 50 years;

-

polymer is one hundred percent inert to all natural loads: chemical, atmospheric and biological;

-

the use of chemical fasteners is a complete absence of tearing loads operating from inside the unit, respectively, eliminating the risk of the appearance of defects of porous material;

-

polymer composite , which is completely fills the hole within aerocrete will operate as securing member between the anchor (stud) and the hole wall.

Now about the drawbacks:

-

first of all, it should be noted that chemical anchors is a pleasure not from cheap , besides drilling holes in the walls of gas silicate blocks will have to be deep, which means material consumption will be large ;

-

composite material bad feels at high temperatures , reducing its technical characteristics;

-

unfortunately, there is no reliable information how reliable this method is.

The video tells how to choose the right chemical anchor:

Summary of the information given

So, all the above methods do not give an absolute guarantee that the power plate will be securely fastened to the end of the wall, built of gas silicate blocks. You can use other options that we did not discuss in this article, but the essence will be the same - any fastener, once inside the porous material, will begin to act on it negatively.

The reason is the work of the fastener for bending and the low strength of the gas block itself. Therefore, we recommend using the only correct option - mounting the power plate on a reinforced belt of concrete solution poured over the wall.

It may be interesting! In the article on the following link read about the correct control over the construction progress - technical supervision.

Formation of armored belt

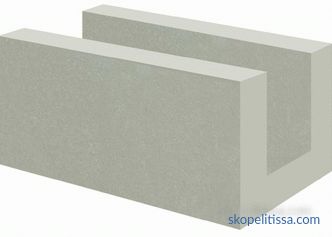

If we consider the instructions and guidelines for fastening the mauerlat to walls erected from gas silicate blocks, then they consider only one option - to install the beams on the reinforcing belt. The technology of pouring the armored belt is simple, because the manufacturers of gas blocks have taken care to increase the range of their products due to special elements. They are intended only for laying the last row.

They have a characteristic shape in the form of the English letter "U", therefore, they are often so and called - U-blocks. For its purely constructive purpose, this kind of gas silicate blocks performs in the wall the functions of permanent formwork, where a metal frame of steel reinforcement is installed and concrete solution is poured.

At the same time, manufacturers today offer several variations of blocks for armored belt, in which the notch is located not only in the center, but also with a slight offset. Plus, several types in terms of dimensional parameters. Therefore, it is very easy to choose this U-shaped element for the thickness of the wall and the main blocks.

The process of forming an armored belt itself is quite simple:

-

U -shaped elements stack onto the last row of solid blocks using adhesive composition;

-

inside the formed groove stack the reinforcing frame ;

-

to the last weld or tie with wire studs with a step equal to the step of laying the rafter legs;

-

pour concrete ;

-

after it dries out the waterproofing material ;

-

are laid on mauerlat lumber , which are pre-made from version;

-

that is, the mauerlat should be put on vertical protruding studs ;

-

on the ends of the studs put on wide steel washers and tighten the nuts;

-

press the nut nuts to armored .

The video shows the technology of pouring armored belt onto a wall of gas silicate blocks:

This could be interesting! In the article on the following link, read about the original residential house in the trees - a modern project in Berlin, Germany.

Conclusion on the topic

So, we tried to deal with some ways of fixing the power plate for a gable roof for a house of aerated concrete. In fact, the ideal option is associated only with the formation of a reinforcing belt, filled with concrete. Moreover, the technology of casting is simple and inexpensive. So drop all other options. You should not risk, you should not avoid small additional investments. After all, the quality of the final result is more important no matter how you achieve it.