The drainage system facilitates the removal of excess moisture from the soil at the site. This is necessary to preserve the integrity of the foundations and walls of the basements of buildings. Asbestos-cement, plastic, and ceramic drainage pipes are used in the drainage system. Each version has its own characteristics of installation, the valid life.

Why do I need a drainage system

The construction of any object must begin with a study of the soil, groundwater level. If you do not perform a set of measures that will allow to drain excess water from the soil, then the following negative processes may occur:

-

subsidence or destruction of the foundation;

-

freezing of the walls of the residential building;

-

flooding of the basements and cellar;

-

formation of mold and fungi on the surface of the walls and floor harmful, can cause allergic reactions and respiratory diseases);

-

waterlogging of land on the site (it leads to the death of sazhdeny)

-

and ice water accumulation on garden paths.

Important! Excessive moisture saturation of the soil causes a change in its chemical composition and microflora.

What should be the pipes

Apply drainage pipes with full or partial perforation. With full perforation, the entire surface has holes that are located around the circle at an equal distance. Products with partial perforation are permeable only from above, they have only 3 rows of holes. In order for the water drainage system to be effective it is necessary to competently draw up a project and select the optimal type of pipe for drainage.

In areas where groundwater is highly suited to the foundation, systems must be constructed for their removal. Pipes for drainage system have lower than freezes through the soil. Their diameter is determined in accordance with the individual parameters of the site.

The products used must meet the following requirements:

-

provide a smooth flow of water;

-

have high mechanical strength;

-

the inner surface with maximum slip and smoothness;

-

with a large flow can withstand considerable pressure inside;

-

able to withstand large temperature differences.

In addition to internal pressure, the drainage pipeline should not bend from the pressure of the soil, its seasonal displacements. When products are made of a material that does not withstand low temperatures poorly, heat insulation technologies are used.

Important! If there is a possibility of ingress of foreign objects or the formation of blockages, then coarse filters are installed in the discharge system.

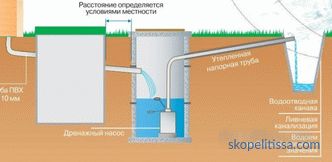

To minimize the internal pressure, together with the discharge elements, a downpipe system is installed in the ground, it is called the surface pressure. It enters the general drainage network, diverts water coming from sediments.

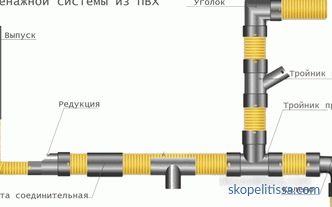

The drainage system consists of interconnected pipes with holes, drainage trenches, wells, connecting fittings and additional elements. Through the holes in the pipes, water is collected and discharged.

What must be taken into account when installing the drainage system

The device of drainage networks is produced after the completion of construction of the main objects. But in some cases, it can and should be mounted at the preparatory stage:

-

The section is flat with no minimum slope. Groundwater will accumulate in large quantities.

-

The level of groundwater is less than 150 cm to the ground.

-

The main stratum of soil consists of loamy rocks and clay, which do not pass moisture well.

-

The plot of land is located in a region where, according to statistics, precipitation is above normal.

The design necessarily takes into account the depth of the foundation of the main objects on the site.

Attention! If an object with a deeper foundation is erected near a residential house, it can disrupt the natural drainage of groundwater and cause their accumulation. This will lead to flooding of the basement, the basement of a residential building.

When there is a concrete pavement around the building foundations, there are many asphalt paths on the site, the natural circulation of water is disturbed. In this case, the storm system connected to the drainage system must be mounted.

Types of drainage pipes

All drainage pipes can be grouped according to various criteria.By the type of material from which they are made, there are six varieties.

Ceramic. Produced from refractory clay with mineral additives.

Asbestos-cement. It is made with a diameter of 10-20 cm. One drainage pipe of asbestos cement can weigh up to 52 kg. Couplings from the same material are used for the connection. Increased permeability is achieved by making cuts in the surface of the pipe, arranged in a checkerboard pattern.

Metal. They have considerable weight, they can corrode.

Plastic . They are made of low or high pressure polyethylene (HDPE and LDPE), polypropylene, polyvinyl chloride. The presence of corrugated walls and stiffeners allows you to evenly distribute external pressure.

On our website you can find contacts of construction companies that offer installation and sewerage design services. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Concrete. It is difficult to perforate, they are heavy.

From porous expanded clay or plastic concrete. Moisture inside enters through the pores in the walls.

According to the structure, drainage pipes are divided into single-layer flexible corrugated and two-layer outside with a corrugated surface and smooth inside. Some models of the latter have built-in filter sheaths made of geofabric with stiffeners that prevent contamination of the holes with sand. Single-layer applied in deep bedding.

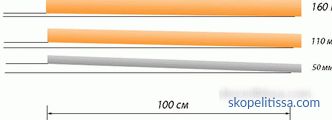

The most popular models are pipes with a diameter of 110 mm with a protective layer of geotextile. They are mounted without an additional filtering system.

Depending on the stiffness, drainage pipes are divided into two types.

Flexible models. Suitable for creating curvilinear flows. Such elements are characterized by lower ring stiffness. Some are sold in reels of 40-50 meters.

Rigid drain pipes. Used for straight laying. They are made thin-walled with a diameter of 5-15 cm and thick-walled with a diameter of 15 cm. The latter are made up to 6 m long, when stacked they are joined with connectors, turning elements.

It might be interesting! In the article on the following link read about the drain pump for sewage.

Ceramic and asbestos-cement

Drainage pipes from asbestos-cement mixture are 10-50 cm in diameter, 3.95-5 m long. As a rule, such pipes are partially perforated. Asbestos cement drainage pipe is easily maintained, but due to too much weight and complicated installation it is rarely used. Service life is no more than 20 years.

Ceramics are made using firing furnaces. The press is molding from sand-clay mixture with the addition of alloying substances. Perforation is performed at this stage. Then the blanks are hardened in furnaces at temperatures up to 1300ºС.

Ceramic drainage pipes with dimensions of 50-70 cm are connected by couplings. The diameter of the products is 5-30 cm, length is up to 0.3-1.5 m. The drainage pipe made of ceramics has the following advantages:

-

service life up to 30 years;

-

resistant to seismic and chemical processes;

-

internal and external friction coefficient is minimal.

Ceramic products are actively used in landscape design to drain the desired areas.

Main advantages of drainage pipes made of plastic

Plastic drainage pipes, varieties which have a corrugated surface, are most often used in modern construction. Such popularity is caused by a large number of advantages of products of this type:

-

service life up to 50 years;

-

high resistance to corrosion processes;

-

low weight with high strength;

-

do not collapse under the influence of aggressive media;

-

are easily transported and assembled;

-

the maximum smooth structure of the inner surface prevents clogging;

-

affordable cost.

When using drainage pipes with a filtering layer of geotextiles, regular washing of the system is not required. For networks with normal and low load, products with a diameter of 110-200 mm are suitable; pipes with a diameter of 300 mm withstand an increased load.

Tip! If from the installation of the sewer system there are pipes with a diameter of 10-11 cm, then drainage can be made from them. The surface is perforated with a drill, then the products are wrapped with geotextile along the entire length.

Plastic drainage channel types

Several types of plastic drainage channels are produced:

-

Corrugated single-layer products with or without holes (HDPE). Models of rigidity class SN2 are used at a depth of less than 2 m, class SN4 at a depth of up to 3 m.

-

Corrugated double-layer products made of HDPE or LDPE with smooth walls inside. Stiffness class SN6, used at a depth of less than 4 m. Such pipes are easy to transport and install.

-

Corrugated flexible products with stiffness SN8, used for laying at a depth of 10 m.

-

Double-layer corrugated pipes made of HDPE with a smooth inside, stiffness class SN8. Products do not have a filtering layer; they are used at a depth of 8 m.

Double-layer drainage pipes are most often used for laying at shallow depths. The smoothness of their internal walls ensures maximum service life and efficient outflow of water. Corrugated top layer with stiffeners has high strength.

It might be interesting! In the article follow this link read about drainage pipes.

The most popular pipe types are Perfokor and Logistics. "Perfokor" is made from high modulus polyethylene with the addition of mineral components. They have increased rigidity, available in diameter 11 cm, 16 cm, 20 cm, 40 cm.

"Logistics" has a flat rectangular shape, made of HDPE. It is equipped with additional internal reinforcing elements. The particular advantage of the variety in compactness, which is important for transport.

See the video of the drainage pipe variety:

PVC Products

The use of pipes of this type is typical for surface installation. Models with a diameter of 5-30 cm, with corrugated single-layer or two-layer walls are produced. Most products have perforations. PVC pipes are easily connected to the pipes of concrete and plastic wells. Connecting elements are used with snap mechanisms.

The installation of networks of such pipes is simple and quick, but a cushion of rubble and a geotextile protective layer is required. Products with stiffness classes SN 2,4,6,8,16 are produced.

Drainage PND pipes

The physical characteristics of the HDPE products ensure their use in any networks. Different types of pipes have rigidity SN4 and SN8. Depending on the structure, there are PND products with one or two layers, there may be a perforated pipe for drainage or without perforation.

The diameter can be 5-70 cm, the pipes with the maximum diameter can withstand heavy loads. For the installation of the drainage system is used sockets, couplings or welding.

While giving preference to these drainage pipes, it should be remembered that the material used in the production of HDPE products is combustible.

How to determine the slope of the pipes

The slope of the drainage pipe depends on various factors:

-

diameters of the pipes used;

-

varieties of drainage systems;

-

features of the surface of the house adjoining site.

If you make calculations incorrectly and select a larger angle than necessary, an excessively rapid flow of water and the appearance of silty sediment will occur. System clogging will occur frequently.

When setting the angle less than necessary, water will stagnate inside the channel, which will cause it to overflow and stop functioning. Excess moisture will remain in the ground.

Important! The calculated slope has a fractional value. It is obtained by dividing the required inclination of the pipe to its length, expressed in meters. The indicator 0,003 will mean that the level of the difference in the meter section of the pipe should be 3 mm.

This indicator is registered in building codes, SNiP.Let us give specific values for drainage systems from standards:

-

with a pipe diameter of 200 mm, the minimum inclination angle is 0.007 m / m, with a pipe diameter of 150 mm - 0.008 m / m;

-

a kind of natural territory coverage also matters: asphalt - 0.003, paving stones - 0.004, crushed stone - 0.004, large stones - 0.005 m / m;

-

for separately placed trays, the optimal indicator is 0.005 m / m;

-

for drainage channels - 0.003 m / m.

The installation of pipes under a slope is necessary even for land allotments with a slope, despite the natural outflow.

If this is not done, the groundwater will gradually thin the soil, reducing its strength. Similarly, they will affect the foundation of buildings. On inclined plots it is rational to mount a combined system of open and closed type.

It may be interesting! In the article on the following link read about drainage around the house.

Determination of parameters of drainage

In order for the drainage pipeline to be effective, it is important to make correct calculations of its parameters. The most popular is the ring pattern, when the channels are located around the perimeter of buildings.

In the calculations determine the depth of the foundation of the building and the angles of inclination. For any type of materials used in the installation, the bookmark is performed 0.3-0.5 m deeper than the cushion of the building foundation. The recommended channel drop in the place of flow should be more than 1% per meter of pipe.

For more information about drainage systems and their installation rules, see the video:

In ring systems, the distance between the upper parts of the trenches and the walls of the house should be not less than 3 m. Concrete blind area around the walls of the building - not more than 1 m.

When performing calculations, the lowest point of the system is first planned, where water will be discharged. Based on the obtained value, determine the depth of laying the upper part of the channel. Measure the remoteness of the highest point from the bottom and set a slope of 1%.

The upper point, as a rule, is located at the level of the building angle, and the lower one is at the installation site of the collector well.

For systems where it is impossible to install a well at the required depth, it is recommended to use drainage pumps, which will force out the incoming water.

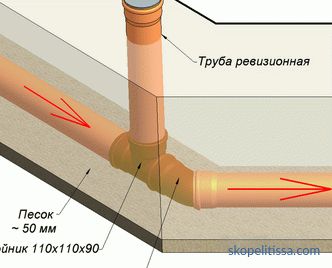

Installation sequence of the drainage network

The installation work on the drainage system is performed as follows order:

-

The area is marked, the locations of the drainage channels are determined.

-

Trench excavations for pipes of rectangular or trapezoidal shape are excavated. Their width should be 0.4 m larger than the diameter of the pipeline. Trenching distance depends on soil type.

-

The bottom of the trenches is compacted.

-

Down a layer of sand and rubble is laid. The thickness of the layers should be at least 0.2 m. For systems where pipes are used without filters, it is necessary to lay filter geotextile on a rubble pad.

-

The pipes are cut to the desired length and laid in trenches using connecting fittings. Partially perforated pipes are laid downwards.

-

Pipes are wrapped in geotextile, which is fixed by a cord.

-

The ends of the pipeline are led to the manholes which will allow to use the collected water for technical needs or to distribute it back into the soil.

-

Above the laid channels, they are filled with rubble and sand, the layers are at least 0.2 m thick.

-

The ditches are completely covered with soil.

With the right choice of materials and high-quality installation, the lifetime of the assembled system will be up to 50 years.

Use of pipes in air conditioning systems

Products have extended use, they are actively used in air conditioning systems to drain the condensate formed on the inner parts of air conditioners. Drainage occurs in the sewer network or on the street. In this connection with the sewage system allows you to get a completely autonomous system.

In such systems, plastic products are used that differ in moisture resistance, strength, and high throughput. Their surface can be smooth or corrugated. The first have a low cost, but require connecting elements when cornering. Corrugated pipes are more elastic and easier to assemble.

Common installation errors for systems

Incorrect calculations and the selection of bad materials can completely disrupt the functioning of the system.The most common errors are the following:

-

The type of soil is not taken into account when choosing a type of pipeline.

-

The absence or incorrect calculation of the angle of inclination of the channels.

-

The system does not provide for the discharge of collected water from a well into a natural reservoir or sewer.

-

Lack or insufficient layer of filtering, geotextile.

-

No holes are provided in the pipes.

-

Bad installation.

See the video for details of the installation of the drainage system:

Considering the drainage pipes available on the market, which ones can you choose? think for a long time, because there are many of them. Of course, this is a personal matter for everyone, but if you turn to specialists, they will quickly help you choose suitable pipes for installation of the drainage system in your yard, and if you trust them to work, then you can avoid common installation errors.

It may be interesting! In the article on the following link read about the drainage well.

Conclusion

The need to construct a drainage system at any site is beyond doubt. For the system to work properly, it is necessary to preliminarily examine the soil, carry out calculations and perform a high-quality assembly.