Proper removal of rain and melt water from rooftops is a requirement that increases the operational life of foundations and walls of buildings and structures. Therefore, a roof drainage system is installed under the roofs, which collects and removes water through vertical pipe risers. But what's next, where does the discharged water go - there are two options: storm sewers and pavement gutters. In this article we will talk about the second, what it is made of, what types it happens, what are the requirements of GOST in terms of technical characteristics and dimensions, and also tell about the method of installation of pavement drainage.

Types of pavement gutters

The classification of the drainage water system of the paving type is formed according to the materials from which the pavement drains are made. There are only three positions:

-

metal ;

-

plastic ;

-

concrete .

Metal gutters

Trays for water drainage are usually made of black carbon steel. Finished products are subsequently painted or coated with other protective materials in order to increase the operational life of the product. On the market there are gutters of galvanized steel, which have a longer service life, as well as coating on both sides with a polymer composition.

It should be noted that the tray system of unprotected metal gradually loses its position. Although in many characteristics it is preferable to other species. For example:

-

metal has increased strength ;

-

steel trays are not so heavy as concrete products;

-

if they are properly treated with protective compounds, they can serve on the street for more than a dozen years;

-

possibility to carry out repairs directly at the place of installation.

However, this type of pavement gutter has its own drawbacks:

-

this is noisy construction when water moves along it;

-

rapid corrosion of metal in adverse operating conditions;

-

color design poor;

-

installation is carried out by installing the gutters in concrete, which is additional cash expenses .

More often on the market you can find metal drainage trays coated with polymers. They have a longer service life, plus an increased range in terms of decorative design. Of course, higher and corrosion-resistant characteristics.

Plastic variety

In general, plastic products pushed a large amount of materials from the market and products made from different materials. Then that plastic:

-

does not corrode under the influence of the negative effects of humidity and water;

-

has a minimum specific weighing , which facilitates installation and transportation;

-

material is noiseless;

-

it is inert to biological and chemical activity from different materials and substances;

-

low price , which will surprise any consumer4

-

huge variety colors;

-

easy to install ;

-

long lifetime .

As for the shortcomings of plastic pavement drains with a grating, this is a large number of fakes that have littered the modern building materials market. They spoil the whole picture in terms of short life and reduced technical characteristics. For durability, such products are inferior accommodated. So when you purchase you need to require a certificate of quality.

On our website you can find contacts of construction companies that offer the design and installation of drainage systems of any complexity. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Concrete gutters

Here I must say this: this is the hardest, but also the most durable material with a long service life. Of all the options offered, he and the most expensive. For comparison; the price of the pavement plastic drain with a grating is 1300 rubles at the rate of 1 m length, width 015 m, depth 0.2 m. Concrete costs 1500 rubles with the same dimensions of the tray. Please note that this is a cost without a protective grid, which will have to be purchased separately.

It should also be noted that today polymer-concrete troughs have appeared on the market, which have significantly increased their technical characteristics. This is not only strength, but also service life.

To the advantages of concrete sidewalk trays, add 6

-

one hundred percent refractoriness ;

-

high frost resistance ;

-

one hundred percent waterproof .

And if there are many variations in the size and shape of the section of the tray, the color scheme leaves much to be desired. And this is the only drawback (considering the price).

The second type of classification

There is another separation of gutters according to their installation, or rather, the depth of location. These are:

-

Shallow-depth without gratings, which are more often installed along the edges of the walkways, sidewalks and platforms. Their task is to divert precipitation and melting snow that flows from the surfaces of the designated elements of the territory design.

-

Deep burial , covered with gratings. Depth can be different, it depends on the purpose of the storm sewer. And, of course, the grilles perform purely barrier functions so that no one will fall into the trays.

Lattices for the east

Purpose of the grids - fencing trays and do not give gutter litter. And since they are located on the surface of sidewalks, blind areas and platforms, they are subject to quite stringent requirements with respect to loads. They must be durable, especially those that use the alleys, parking and areas with heavy traffic. Therefore, gratings are mainly made of cast iron, steel or high-strength plastic. There are also brass lattice designs on the market. But they are usually acquired by people who are not poor.

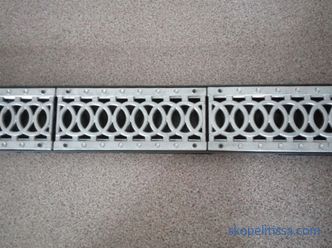

We add that the lattices for the trays are a variety of the lattice part. Here, the models are in the form of square cells or round holes located over the entire surface of the element, with longitudinal and transverse slots, as well as diagonal. Manufacturers offer and openwork grilles. In the photo below, just such an option is shown.

It might be interesting! In the article the following link read about plastic roof drains.

Features of the installation of pavement drainage

To begin with, the storm sewer is a gravity-flow system. Therefore, its elements are laid at a slope of 3-5 °. Minimum bias is used if the trays are used before entering buildings. Maximum, if stormwater is laid along the tracks or along the perimeter of the sites.

If the thickness of the installed drain is equal to the thickness of the paving slab, then it is mounted on the base under the tile. If the embedment is carried out deeper, then a concrete base with a thickness of 10-15 cm is arranged under the trays.

If the tray drain system is placed on the roadway, then a concrete structure with a formwork installation is arranged under the gutters.

Let's consider both options more specifically.

Option # 1 - on a sandy pillow

In principle, paving slabs with a drain shall be laid using standard technology. That is:

-

form a platform for facing with the help of digging a trench (for a track) or excavation under a platform;

-

geotextiles are laid ;

-

they are covered with sand with a thickness of 10-15 cm, leveled and tamped;

-

poured crushed stone with a thickness of 10-15 cm with alignment;

-

spend installing curbs around the perimeter of the concrete solution, they must be placed horizontally ;

-

fall asleep dry mix of sand and cement in a ratio of 1: 1;

-

along the edges of mount gutter on the street

-

then begin to lay pavement , filling it with the whole area of the walkway or platform;

-

after coating water the finish and the trays with water;

-

fill between them the gaps with the same dry mixture;

-

clear of the last trimmed territory;

-

and once again sprinkle with water .

If alleys or platforms will be subjected to heavy loads, the gutters and paving slabs are placed on a cement-sand mortar with a cement-sand ratio, like 1: 3.

The video shows how to construct a blind area at home with installing plastic sidewalk trays for drainage:

This can be interesting! In the article on the following link, read about the prices for the installation of drainage systems.

Option # 2 - with a recess

To do this, at the place of laying trays, trenches are dug out, the bottom of which is cleared of stones and leveled to the required slope.After that, they are covered with sand with a layer up to 20 cm with tamping and setting a bias angle.

If the depth of the depth is small, the trays are mounted directly on the sand cushion, interconnected according to the rules recommended by the manufacturer, and then they pour the soil mixed with sand under the lateral parts of the grooves. Be sure to carry out tamping backfill.

If the burial size is large, then large-sized trays are used as a storm sewer. That is, their weight is significant. So, under the east will have to pour a solid foundation. The simplest option is a concrete mortar with a thickness of at least 10 cm. Therefore, a more durable cushion structure should be laid under the base. This is done as follows:

-

poured coarse sand with a thickness of 10-20 cm, which is leveled at the angle of inclination of the laid sewer system and tamped it;

-

poured a layer of crushed stone 15-20 cm thick with tamping and leveling under the slope;

-

poured the concrete solution , and also aligned at an angle;

-

after drying the concrete mix the elements of the gutter are placed on the base;

-

they are joined to each other with special grooves along go to the lock joint groove-stud, which are located on opposite ends of the chutes;

-

if necessary, seal the joints by applying a sealant or using rubber or polymer gaskets;

-

make the filling of soil and sand;

-

at the end, gratings are placed on top of the structure.

Usually, masters who have long been engaged in the installation of open storm sewers must check the laid elements of the drain. Just at the very beginning of the system pour a certain amount of water. The latter should be strictly directed in the opposite direction. It should not stagnate in trays, and this is a sign of properly performed installation operations.

Please note that in two versions, the upper ends of the gutter elements should be flush with the face of paving slabs or any other finishing material: concrete mortar, asphalt, paving stones and so on. This also applies to the lattice, which closed the drain.

The video shows how to properly install the drainage trays on a concrete base:

It might be interesting! In article on the following link read about the highlight of the landscape - "floating" stairs and garden paths under which grass can grow.

Conclusion on the topic

So, we tried to introduce you to the section of construction related to pavement gutters (with or without grills). In fact, this is one of the most important systems by which rain or melt water is removed from the surfaces of paths, alleys, grounds and blind areas. That is, with their help, a directional movement of water is created, away from buildings, structures and open areas along which people or vehicles move.