Today we will tell how a building element such as a slab for a garage is properly poured with concrete. With the simplicity of the design itself, there are many serious moments in it that affect the quality of the final result. Therefore, we consider the dimensional parameters of the slab structure, we will conduct an example of the calculation of the reinforcing cage and point out the technological processes of filling the floor in the garage in the form of a plate.

The slab foundation

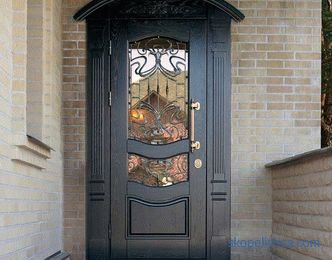

To begin with, the foundation for the garage is the stove, the structure is very reliable, but expensive in terms of material consumption. He has a big plus: the foundation itself will simultaneously serve as a floor base. And if you properly hold the hardening of the surface, then such a floor will last more than a dozen years. Purely structurally, this is a monolithic slab in which a metal reinforcing frame made of steel reinforcement is laid to increase the strength characteristics of the foundation.

Advantages and disadvantages

Let's start with the advantages of this design:

-

In essence, the plate is a floating platform , which is not terrible complexity of the soil. It can even be poured on mobile soil.

-

Low bedding groundwater for the plate is not a problem. The garage will always be dry. And even if the water level is high enough, a small layer of simple waterproofing saves the day.

-

If there is a need to put a heating system underfloor heating in a slab foundation, then this is not the biggest problem. The main thing is to think everything through and calculate it at the garage design stage.

-

The slab foundation - the structure is rather thick, so neither rodents nor the insects will penetrate through it.

The only drawback, as already mentioned above, is the high cost of building materials: concrete and reinforcement. Accordingly, the budget allocated for its facilities will be larger than for the construction of, for example, a strip foundation.

Step-by-step instructions for constructing a slab for a garage

Consider the process of pouring slabs under the garage using the example of a standard structure measuring 4x6 m. Like all construction processes, the construction of a slab foundation is divided into two main stages: preparation for pouring concrete solution and the pouring itself.

Stage 1 - preparatory

First of all, the site is marked for construction. That is, on the ground with the help of a peg and twine, the boundaries of the garage with sides of 4 and 6 m are determined. The resulting rectangle is checked along two diagonals. They are simply measured and compared. Their length must be equal.

Next, they dig out a pit with a depth of 0.3-0.5 m. This parameter depends mainly on what materials the garage itself will be built from. If it is a brick or concrete blocks, then it is necessary to dig out to the maximum. If these are blocks of cellular concrete, then at a minimum.

The bottom of the excavation is leveled and covered with two layers: bottom crushed stone 10-20 cm thick, top sand is the same thickness. Both layers are pre-leveled and tamped. If you want to conduct waterproofing slabs, then do it right now. The easiest way is to use bitumen-based roll material, for example, roofing felt.

It is laid at least in two layers. In this case, both of them are laid stripes in perpendicular directions. The strips themselves are laid out overlapping each other with an offset of 10-12 cm with the obligatory closing of the edges of the pit. That is, the waterproofing layer must not only close the cushion, but also the walls of the pit. Fasten strips of roofing material with bitumen mastic.

Calculation, assembly and mounting of the reinforcing layer

For the assembly of the reinforcement cage is used steel reinforcement with a diameter of 10-12 mm. It is collected in the form of a lattice with cells of 20x20 cm. It is possible less or more, this option is optimal.

The first step is to calculate the number of reinforcement bars required. The dimensions of the building are known, but you need to know that the bars of the reinforcement should not reach 5-10 cm to the edges of the foundation. For example, if the length of the garage being built is 6 m, then the length of the longitudinal elements should be 5.8 m. Transverse 3.8 m with a slab length of 4 m.

Now it is necessary to calculate the required number of longitudinal and transverse reinforcing bars. Since their installation step is 20 cm, that is, 0.2 m, then in the transverse direction of the longitudinal elements will be: 3.8: 0.2 = 19. Be sure to add another element, because this calculation does not take into account the last extreme rod. That is, in general, 20 pieces of reinforcement will be obtained with a length of 5.8 m.

The same is done with the calculation of the number of transverse bars: 5.8: 0.2 = 29, add "1", it turns out 30 elements with a length of 3.8 m. For information, we will show how many reinforcement is required for monolithic slab structures for a 4x6 m garage.

(5.8x20) + (3.8x30) = 230 m. Since the length of one reinforcing bar is 11.7 m, our foundation will require: 230: 11.7 = 19.65 pieces. Round up to 20 bars.

On our site you can familiarize yourself with the most popular projects of "small forms "for a private house - from construction companies represented at the exhibition" Low-Rise Country ".

So, the amount of reinforcement is known, it is cut to size and placed on a waterproofing layer in the form of a grid of 20x20 cm. The reinforcement cuts are tied together with a knitting wire. It is better not to use electric welding, because it is a rigid connection, and it may not withstand the stresses of a car. The wire connection is moving. When assembling a reinforcing lattice, it is necessary to strictly observe its location. That is indented from the edges within 5-10 cm.

And one more important point concerning the reinforcing frame. It should be located in the body of the concrete structure. That is, below it and above it must be a concrete solution. Therefore, the reinforcement grid should be raised, at least to a height of 5 cm. Therefore, pieces of bricks, blocks or stones are evenly placed under it. Today, in the building stores special stands are sold from metal or plastic. First, they are the same size, which simplifies the installation of the frame in the same horizontal plane. Secondly, these elements are stable and it is convenient to lay reinforcement on them. The photo below shows such an element.

Installation of the formwork

The solid foundation for the garage is poured with a ledge above the ground . This height can be quite large - in the range of 10-15 cm, or small - 5 cm. Regardless of this, formwork is installed around the perimeter of the future structure. It is better to use edged boards with a thickness of 20-25 mm and a width that defines the height of the upper part of the poured structure. For example, if it is 10 cm, then the width of the board should be 100 mm.

The formwork is set exactly around the perimeter of the pit. Its elements from the outside are reinforced with pegs and props (wooden or metal), and also two adjacent boards in different directions are braced.

On our site you can familiarize yourself with the most suburban areas in the Moscow Region home . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

Stage 2 - pouring concrete solution

This process is the simplest. Concrete is poured at the same time to completely fill the space inside the pit and the limited area of formwork. The most important parameter of the slab under the garage is the thickness.

This size varies in the range of 15-20 cm. If the garage is built for a large car, then it is better to increase the thickness to 30-40 cm. If the slab structure is poured in according to the last parameter, then the reinforcing frame is assembled in two layers with a distance between them within 20 cm.

As for concrete, for the slab foundation, you can use a solution of the brand M250, but better M350. The price component of different brands does not differ much, but the latter is much better in terms of strength characteristics.

So, if the concrete mortar is poured, you need to take care of it in terms of drying. In the first few days, its surface must be watered. If the weather is hot, it is recommended to cover the plate with plastic wrap.

After 7 days, formwork is removed. It is possible to load a concrete structure, that is, to erect walls, only after the concrete solution has at least 70% of its brand strength. For example, at a temperature of + 20 ° C at normal humidity, the structure will gain such strength within 10 days. But in this situation, no need to hurry.

So, the monolithic slab of the foundation for the garage is ready. You can build the building itself. In principle, such a floor is already guaranteed durable. But it is recommended to consolidate it. What are the ways and technologies.

The video shows how to build a slab foundation for a garage:

It might be interesting! In the article on The following link reads about garage projects with a hobby block .

Hardening the garage floor

There are several traditional methods, as well as new technologies.

-

Cementation .It is carried out at the stage of solidification of the slab base, while it is still wet. Simply sprinkle cement over the floor with a thin layer and rub it with a spatula or trowel. The main task is to rub the cement into the concrete base.

-

Installation of stone or concrete tile . One of those options that is not very popular among private developers. Too expensive.

-

Processing of the concrete floor with special impregnations based on polyurethane or epoxy. Such compositions penetrate deep into the body of a concrete mortar (up to 7 mm), strengthening it many times over. At the same time the surface of the plate becomes waterproof. Yes, and chemically active substances to this layer is not a hindrance.

-

Painting . For this purpose, special paints based on polymers are used. In fact, this is a decorative waterproofing that does not let moisture through. But according to the strength characteristics of these paints are quite durable.

-

Self-leveling floors based on cement or polymers . Another effective way to reinforce concrete floors in a garage.

It might be interesting! In the article on the following link, read about a country house with a veranda .

Conclusion on the topic

A slab foundation is considered the best solution if the task is to construct a garage on fragile soils with a high level of groundwater flow. In many situations, this is the only option. The most important thing is to calculate everything correctly: from the depth of the pit, the amount of reinforcement to the thickness of the plate itself. There are no secondary elements or operations in this design. The quality of the final result depends on each of them.