The roof, as the main protective element of the house, requires increased attention to the choice of its components. The article describes the principles for determining the required number of screws for arranging the roof of corrugated board. The proposed material will introduce you to the factors affecting the number of fasteners; You will find out how many self-tapping screws per 1m 2 professional roofing sheet will be required in one way or another, which parameters determine the quality of the hardware and what to consider when buying them.

About attention to accessories

Profiled sheet refers to the number of materials with a wide range of applications . In the suburban house building it is used for cladding wall or roof structures, as well as in the construction of fences. Especially popular material is used as a finishing coating for the roof. The reason for this love is its performance: durability, low weight and easy installation. An important factor is the budget cost and the variety of colors and profiles, allowing you to choose a professional flooring for any architectural project.

When constructing the roof, the focus is on the quality of the profiled sheet. Each homeowner before buying pays attention to the parameters of the sheet, affecting its operational properties: the thickness of the metal and the protective zinc layer, the type and thickness of the polymer coating. Fasteners are traditionally considered a related product; not only homeowners, but also contractors, wanting to save money, buy fasteners on a residual basis, focusing more on price than on quality.

Such a frivolous attitude to fasteners leads to a very quick leakage, even if the roofing material itself and reasonableness roof structures do not cause any complaints. Small savings on fasteners turn into unforeseen (sometimes significant) time and money to fix defects.

The choice of low-quality hardware for fixing the roof leads to the fact that under the action of atmospheric moisture the screws start to become covered with a corrosive coating and can significantly weaken the installation. In advanced cases, parts just fall off, and the roof loses tightness. The solution to the problem consists not only in the purchase of fixing elements of excellent quality, but also in their proper use, primarily in determining the required quantity. To find out how many self-cutting screws you need to fix a roofing sheet, you need to understand the factors that affect the amount of consumables purchased.

On our website you can find contacts of construction companies that offer the service of reconstruction and rebuilding of houses. You can directly communicate with representatives by visiting the low-rise country exhibition.

About self-tapping screws: what influences their number

The number of self-tapping screws that you need to get a quality result depends on the following factors:

-

Scope of use . Corrugated player can be mounted on the roof, used for finishing the facade of the house, shed or garage, used in the construction of fencing. For each type of work consumption of hardware will be different.

-

Weather conditions in the construction region. The consumption of fasteners is influenced by the strength of the wind and the amount of snow cover; the higher the load, the greater the need for self-tapping screws for reliable fixation. The magnitude of the loads can be found in special tables; its not to be underestimated. Inadvertently fixed roofing can not withstand the pressure of wind or snow and deform (in the worst case - collapse). Anyway, the wrong calculation of screws for corrugated roofing will cause new costs.

-

Coat mounting scheme The professional sheet is cut from rolled steel, therefore its length varies within fairly wide limits (on average from 1.5 to 10 meters). If a professional sheet equal to the length of the slope is used for the installation, it turns out that the laying goes in one row and the number of the required fasteners is reduced.

It can be interesting! In the article on the following link read about the types of roofing sheeting.

Calculation Principle

The question of how many self-tapping screws are needed for 1 m 2 profiled roofing sheets should take into account that for proper installation you cannot do without three types of fasteners :

-

35 mm long . Hardware of such length is suitable for mounting a professional sheet to the structures of wooden crates.

-

20 mm long . Screws of such length are fixed among themselves by adjacent professional sheets, without mounting to the crate.

-

70-80 mm long .Such parts will be required for fixing additional parts (ridge, eaves, corner bars and caps) that perform a protective function.

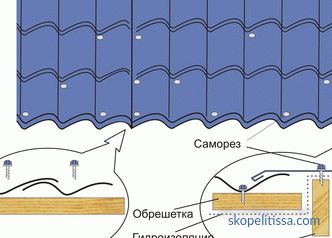

Installation of the roof from the profiled sheet is carried out according to certain rules; mounting points are selected according to the following scheme:

-

Installation work begins from the side nd strips . The imposition of adjacent sheets in the same row is carried out on one wave. The overlap of the upper and lower rows is about 20 cm (which depends on the angle of inclination of the slope).

-

Top and bottom edge of the sheet . The screw is fixed every deflection of the wave.

-

Lateral edges and overlaps . To improve the tightness of the screws are attached to each wave and have not in one line, and zigzag. A pitch of about 0.5 m is set between the attachment points. This method showed its reliability in areas with strong wind loads.

-

Professional sheet area . Screws are screwed through a wave of outrageous (staggered), which helps to increase the reliability of fasteners and avoid overspending of fasteners.

About the roofing self-tapping screw on metal in the following video:

Solution of the problem, how many self-tapping screws on a sheet of professional flooring need on the roof depends on the chosen method of installation. Taking into account this scheme, an example of calculating the required number of screws may look like this:

-

For the roof, profiled sheet with parameters 1.1 by 8 m was selected. 0.5 m.

-

For mounting a single sheet you will need approximately 18 self-tapping screws : for fixing in the upper and lower longitudinal sides - 5 hardware, for fixing the sheet area - 8 more pieces.

-

The total number of fasteners can be obtained by multiplying 18 by the total number of sheets.

-

On average, from 1 to 9 hardware is consumed per 1 m 2 of the roofing surface.

-

Fastener consumption will be increased for other roof parameters. The steeper the roof structure, the tighter the fasteners are. Consumption will also increase in areas with snowy winters.

-

Actual flow self-tapping screws for 1 m 2 professional roofing sheet is always slightly higher than the calculated one; some parts may be lost or be defective, therefore, hardware is purchased with a small margin (at least 5% more).

-

The quality of the mounting screws significantly affects the lifespan of the roof, so you should not resort to a penny savings when purchasing hardware.

It can be interesting! In the article on the following link read about the installation of snow guard.

About features of roofing self-tapping screws

Fasteners for roofing works are made of the following materials:

-

Stainless steel . The most common material of manufacture, such screws are not afraid of corrosion, they are durable, reliable fixation and long term perfect operation.

-

Alloy steel . The addition to stainless steel of certain additives (nickel, chromium) makes hardware resistant to dynamic loads, increases strength and corrosion resistance.

-

Carbon steel . The main advantage of this material is strength and reduced ductility.

About the selection of screws in the following video:

-

Galvanizing . The steel elements are coated with zinc, after which they become silver or yellowish in color and provide additional corrosion protection. Sometimes fasteners are protected by oxidation or phosphating, which is why they turn black and acquire additional durability.

Externally, the screw looks like a screw with a profile drill bit that allows you to fix the fastener without first drilling holes. The mounting screws for roofing work are characterized by the following parameters:

-

Head . More often found hardware with a hex head, but it is also a secret or semi-circular. Parts are attached with a screwdriver or key.

-

The drill bit . Working with screws does not require the preparation of holes; parts are equipped with a tip drill.

-

Ensuring the tightness of the connection. The hardware is equipped with an elastic rubber gasket and a flat washer.

-

Mounting method . Self-tapping screws can be fixed manually, as well as with the help of a screwdriver or a drill with a special nozzle, which significantly speeds up and simplifies the work.

About self-tapping screws: what to consider when purchasing

Hardware for a professional sheet, offered by manufacturers, have the following parameters:

-

Length .The most popular products are 29, 35, 50, 70 mm, generally the length varies between 16 and 150 mm.

-

Diameter . It is selected depending on the thickness of the roof covering and is 4.8-6.3 mm. Such self-tapping screws can independently (without preparation) drill through metal up to 1.2 mm thick.

-

Threaded part . It must be at least 3 mm longer than profiled sheeting.

-

Quantity . The package may contain from 100 to 250 pieces.

-

Color . Self-tapping screws can be selected according to the color of the roofing material used, which makes fastenings almost imperceptible.

-

The protective coating can be paint-and-lacquer . When using a screwdriver, high-quality coating is not peeled off, maintaining the durability of the connection.

When purchasing the required number of self-tapping screws for 1 m 2 roofing sheet, it is recommended to pay attention to such an indicator as resistance to tearing. Fasteners during operation are experiencing significant loads, so their requirements are high. In the manufacture of parts are thoroughly tested. A sign of high-quality self-tapping screws is the indicator of resistance to rupture, reaching 150-170 kg / cm (with allowable 100-102 kg / cm).

High-quality roofing screws do not cause trouble during operation, you can identify them with the following indirect signs:

-

The presence of stamp stamped on the head .

-

The presence of a zinc coating , the thickness of which is indicated on the package and is not less than 12 microns.

-

The paint coating is uniform, without cracks.

-

Washer thickness . Must be greater than 2 mm.

-

The appearance of the rubber gasket . It should not peel off from the washer. Too porous or too hard rubber will not be able to withstand the loads and will cause leakage.

It might be interesting! In article on the following link read about the house with a wave-shaped roof.

Conclusion

In addition to the number of fasteners, it is necessary to decide on the size of the fasteners. Necessary recommendations are usually present on the package. If they are not specified, you can choose the hardware to the desired size yourself. Self-tapping screws of such a length are chosen so that the length of the threaded part exceeds the total thickness of the professional sheets being joined by at least 3 mm.

Rate this article, we tried for you