Decorative blocks for fence posts are used in fences made of different materials - wood, profiled sheet, metal box, forged and welded gratings. They, like facing bricks, are fastened around the pipe, but the installation technology itself differs from the brickwork. They also build fences, in which not only pillars but also spans are partially or fully assembled from decorative concrete blocks.

What is it - a decorative block for the

fence? look at the composition of the components from which make a decorative block for the fence, then this is either ordinary concrete, or its lightweight version - cinder block. Differences between products from different manufacturers - type of filler and technology performance.

In addition to sand and cement, the third main component, filler, can be:

-

gravel or crushed stone;

-

brick breaking or concrete (secondary crushed stone);

-

expanded clay;

-

stone chips;

-

slag;

-

glass breakage.

Note! Glass breakage, as a rule, serves as an "auxiliary", or additional filler, to give the surface a special decorative effect.

As well as ceramic bricks or a cinder block, decorative fence blocks can be solid or hollow. Although only hollow fence blocks are widely used - less cost and weight, lower costs for the foundation and the entire fence.

And blocks for fence posts are only hollow. Except for the hyper-pressed facing brick, which has a similar production technology and can be used for laying the pillar.

According to the method of manufacturing, decorative concrete blocks for the fence are divided into two types:

-

Vibrating casting. The concrete mix has a standard amount of water that provides good ductility and workability. Compaction occurs due to the impact of vibration on the casting in the form installed on the vibrating table.

-

Vibration pressing. The components are mixed with a lack of water - the technology of "semi-dry" concrete. And compaction occurs due to the impact in two directions: horizontal, due to the vibration of the platform, and vertically, due to the clamping force of the plunger.

The advantages and disadvantages are laid down at the level of technology:

-

vibrocast blocks have a smoother surface and a greater variety of colors, but have less strength and frost resistance;

-

vibro-pressed concrete blocks for the fence are more durable and can withstand a large number of freeze-thaw cycles, but are characterized by a rough surface and a small selection of shades.

Given that the fence is not a pavement or a wall that does not carry a wall, the difference in strength is not so significant. And the rough surface is usually masked due to the popular intake block of the decorative effect of the front part - “crushed stone”.

On our website you can find contacts of construction companies that offer construction services and design fences and fences. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

The merits and demerits of concrete block fences

If we talk about decorative merits, a fence made of concrete blocks could theoretically be inferior only to a fence made of processed natural stone. But for fencing of private houses they do not do such, and his only competitors are fences of rubble and facing brick. But they also lose to him in several ways:

-

Higher resistance to mechanical stress. Due to the smaller number of masonry joints and the filling of hollow blocks with concrete solution with vertical reinforcement of the pole and spans, it turns out a monolithic structure.

-

High installation speed. One block in all three sizes exceeds a single ceramic brick, and it is easier to put it. Not to mention the complex installation of a multi-format "wild" stone.

-

A wide choice of various textures and colors. This allows for a greater maneuver for harmonious landscaping.

-

The optimal ratio of price and quality, both in terms of materials cost and installation costs.

Otherwise, the advantages of a fence from blocks are the same like brick and natural stone fences:

-

high service life;

-

good protection of the site from dust and noise if the road passes nearby;

-

reliable protection of the internal territory from inquisitive views;

-

fire resistance and prevention of the spread of "low" fire (according to the classification of wildfires).

The fencing and the concrete fence posts themselves, which are made of blocks, have disadvantages:

-

only professionals can do the work properly;

-

a lot of weight, which requires the construction of a solid strip foundation.

The zero cycle and foundation laying

Traditionally, the installation of a fence made of decorative blocks begins with marking and planning the perimeter of the section.

After noting the passage routes, the installation sites of the pillars (including gates and wickets), they proceed to earthworks.

The depth of laying the underground part of the pillars and its appearance is determined by the bearing capacity of the soil. Usually it is made below the level of soil freezing by 20-30 cm in order to exclude the influence of soil heaving on the fence support.

It may be interesting! In the article the following link read about poles for the fence.

For moist heaving soils, the depth of the trench under the span may be the same as for the column. In other cases, a shallow-deeper foundation is usually arranged, assuming that the weight of the span construction is sufficient to compensate for slight heaving - the standard size is within 40-60 cm.

formwork for monolithic strip foundations.

Attention! The blocks for the posts are larger than for the wall, but they dig a trench for the entire fence of the same width. And the basement tape on the base has the same size for pillars and spans. Only the depth and mode of reinforcement is different.

A cushion of sand and rubble is made on the bottom of the trench, a formwork is installed and the foundation is reinforced, making reinforcement outlets for installing the lower rows of concrete blocks for spans.

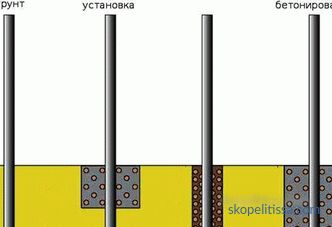

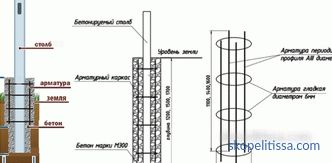

The column reinforcement can be carried out in two ways - by installing the profile pipe in the center or by issuing a bar to the full height of the fence.

Then the concreting of the foundation is carried out. After the initial maturation of the concrete, the formwork is removed, and after a set of design strength is started, the installation of the pillar blocks and spans is started.

Important! The waterproofing of the monolithic foundation for the fence is carried out according to the same rules as for the house. But even when installing the fence on dry sandy soils, it is desirable to make a separation layer between the base and the decorative blocks.

Installation of the fence

Work begins with the installation of concrete blocks for pillars. They are literally “strung” onto a pipe or releasing an arm-belt from the foundation, but not immediately to the full height, but 3-4 rows, flattening out by level and relative to the fence plane. Then the concrete is poured into the cavity, the mixture is compacted, expelling air, and reinforced in the horizontal plane with a laying of masonry net or rod. Thus carry out the installation of the remaining rows on the entire height of the column.

The laying of spans from decorative blocks is usually carried out according to the same rules as for a brick — with the vertical joints extending half the block length.

But taking into account the pouring of internal cavities with concrete and laying steel bar in them , it is rather a decorative device than a necessary condition for ensuring the durability of the masonry by bandaging the rows. Therefore installation of flights with continuous vertical seams is allowed.

Laying of “wall” blocks is performed according to the following algorithm:

-

strung the first 3-4 rows of releases of reinforcement from the foundation;

-

align with the level and in the span;

-

pour the concrete mortar and seal it;

-

connect the following vertical valve outlets for the upper rows;

-

are reinforced in the horizontal plane with a grid or wire;

-

after the initial hardening of the concrete, they proceed to the installation of the next rows.

After the last block has been laid, the fence and the pillars are covered with tops — decorative blocks that adorn the fence and protect cavities filled with concrete from the effects of precipitation. The shape of these elements can be different - flat, pitched, semicircular. And for the pillars, some manufacturers produce special models of the most complex configuration.

You can clearly see how a column is assembled from blocks in the following video:

It is often enough that a cable is laid to the fences that passes through internal cavities coming out on the upper ends of the pillars. This is done to install street lamps, illuminating the perimeter of the site with the adjacent territory.

It might be interesting! In the article on the following link read about fences for summer cottage.

Conclusion

A fence for a house made of decorative blocks is similar in technology to the wall of a monolithic house with permanent shuttering. There are also casting tape foundation, reinforcement, installation on the level of hollow blocks, pouring concrete. And specialists should deal with this - an error in calculating the size of the foundation or a poor-quality mortar will have a negative effect on the reliability and durability of the fence of the house.

Rate this article, we tried for you