The roof of a building is exposed to particularly intense effects of various natural factors, therefore not only the comfort inside the house, but also the duration of operation of the entire structure depends on the reliability and quality of its construction. Particular attention should be paid to the choice of material and the sequence of installation of the layers of the pie of the roof under the metal tile. The article provides information about the materials necessary for arranging a reliable roof - the main performance characteristics, the need for use, installation features, etc. After reading the article, you can monitor the quality of construction work, and if necessary, do not allow them to "save" on the acquisition of cheap construction and insulation materials or "simplified" installation technology.

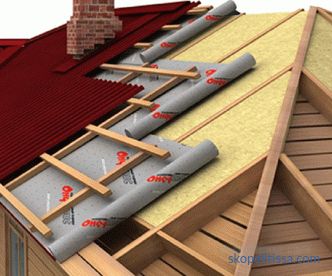

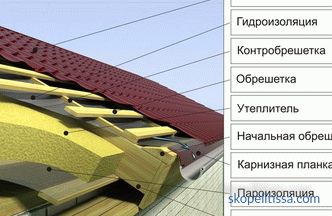

Sequence and purpose of layers of roofing pie of a roof with thermal insulation

Roof pie of metal tile with insulation consists of several layers, each of which has its own purpose:

-

Outer coating . Metal tile or its budget option - metal profile (profiled sheet, corrugated board). Metal profiles are recommended to be used to cover household structures and technical structures in the construction of roofs without insulation;

-

Lathing . Wooden frame to which the outer cover is attached;

-

Waterproofing . It protects the truss system and heat insulation from moisture;

-

Counter lattice . Wooden slats, creating a ventilation gap between the outer coating and insulating materials. Thanks to the counter lattice, moist air and condensate are not in contact with thermal insulation;

-

Sound and Vibration Isolation . Damping elements are part of the roof frame of a large area. Such brands as Izoplast bi-not, Sylomer, etc. are allowed. Roof structures of small and medium sizes can do without them, provided that the support base (flooring) is carefully installed, fiber insulation is used and the technology of metal tile fastening is strictly observed;

-

The rafter system . The set of supporting elements of the roof, which is the basis for attaching all layers of the roofing pie;

-

Thermal insulation . Reduce the heat loss of the building. It is recommended to use fiber insulation materials with a high degree of noise insulation: mineral wool, basalt wool, glass wool;

-

Vapor barrier . Protects the roofing pie from moist air coming from the interior of the structure;

-

Inner counter railing . Wooden slats of small cross section, creating a ventilation gap between the vapor barrier membrane and internal finishing materials;

-

Cladding . Draft: plywood, OSB, drywall, designed for mounting decorative and finishing materials. Decorative: plastic or wooden lining, false timber, decorative panels.

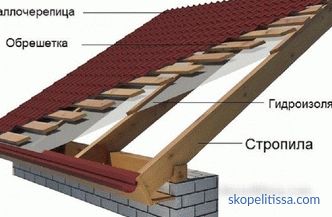

Sequence of Cold Roof Layers

The technology of arranging a cold roof is much simpler than a warm one:

-

The waterproofing membrane is mounted to the rafters with the help of the construction stapler ;

-

Along the truss legs the slats of the contra-lattice are installed;

-

Elements of the batten perpendicular to the rafters;

-

Fixed roofing material - metal.

Cold roofing is used for technical buildings, garages, storage rooms and other outbuildings.

Main characteristics and features of the use of elements of the roof

Roof frame

A standard roof system is used for metal roofing for light roofing materials. The cross section of the bar - 50x150 mm, the step of rafter legs 600-950 mm. As a rule, a pitch of 600 mm is adopted for the convenience of installing insulation materials. This distance allows you to position the whole plates of insulation between the rafters without gaps and without the need to cut them, which will significantly speed up the installation process.

In the northern regions of Russia, it is recommended to use timber with a section of 50x200 mm for rafters. This is due to the need to withstand increased snow and wind loads, and also allows you to place a thicker insulation between the frame elements.

Waterproofing

The choice of waterproofing material that is part of the roof under the metal tile depends from the destination structures. The use of conventional polyethylene film, glassine or roofing felt is allowed to isolate non-insulated roof structures used in unheated technical buildings.

In residential buildings, waterproofing membranes are recommended, despite their rather high cost. For the roof under the metal tile, as a rule, the following types of waterproofing are used:

-

Two-layer polymer - consists of two layers of plastic film with a reinforcing mesh between them;

-

Superdiffusion membrane - characterized by unilateral vapor permeability. Its installation location - permeable side in the direction of the heater, so that the humid air is removed from the insulation in the ventilation gap.

-

Waterproofing with a fleecy coating is also a diffuse material that removes moisture. It also prevents the formation of condensation. It is installed with a fleecy, vapor-permeable side to the insulation.

Any of the waterproofing membranes is laid on the plane of the roof parallel to the ridge, starting from the bottom. The overlap between the panels is 10-15 cm and is additionally glued with construction tape. Fastening to rafters is carried out by a construction stapler.

The counter grille

It is located between the elements of the batten and the rafters , forming a gap between the waterproofing layer and the roofing material. It is made of wood in the form of bars 30x50 mm. If the roof has a complex structure, a large area or a significant length of the slope, then bars of increased section - 50x50 mm - are used for the contombrestock. It is located along the rafters and fastened to them with nails or screws with self-tapping screws 50-75 mm long.

Lath

It is the supporting base for sheet metal. It is made of boards with a section of 50x200 mm or a 40x60 mm bar, located perpendicular to the rafters. In practice, these elements are often used together, if necessary, especially strong fastening of the extreme sheets of metal, in the case of increased wind loads in the region and / or high windage of the roof structure. In this case, the main area of the roof is covered with timber, and the lower part of the slope is covered with solid flooring from the board. The pitch of the elements of the batten depends on the wave of the metal tile and is 800-1000 mm. Fastening is carried out with the help of nails or screws on wood (self-tapping screws) with a length of 60-75 mm.

Important! All wooden elements of the roofing structure must be treated with antiseptic (against fungus, mold, rot) and fire-retardant (increase flame resistance) impregnations. Manufacturers of construction chemicals and offer universal tools for wood processing, significantly increasing the life.

On our site you can familiarize yourself with the most suburban areas in Moscow region home . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

Thermal insulation

A traditional thermal insulating material, a pie of the roof under a metal tile with insulation, is mineral (basalt) wool. It is sold in rolls and plates. The size of the plates for most manufacturers is 1000x600x50 (100) mm. They are installed in the interracial space by a counter.

The use of plates is preferable, since when they are laid, no additional fasteners are required to hold the material between the rafters. The insulation is laid as tightly as possible, but it must be ensured that the material does not deform or shrink.

For the insulation of technical buildings, it is more advisable to use polystyrene foam, as it is better resisted by moderate mechanical stress and does not need additional protection from the inside of the structure.

The gaps between the polystyrene foam plates and between the insulation and the rafters should be filled with mounting foam. This will not only eliminate the leakage of warm air from the room, but also give the whole structure additional strength.

Vapor barrier

It is one of the most important layers of pie roof under the metal tile. Its main purpose is to protect thermal insulation materials from the influence of warm, humid air coming from inside the premises.The use of vapor barrier is mandatory when using fibrous heat-insulating materials, because absorbing moisture, mineral wool significantly reduces its effectiveness.

The most common vapor barrier material with an affordable cost is glassine. However, it has low strength and durability. Polypropylene "woven" membrane is more durable and efficient. It is manufactured under many brands and is positioned by the manufacturer as a universal insulation tool - hydro-vetro-vapor insulation. In addition, this material prevents condensation.

Sound and vibration insulation

One of the specific properties of metal tile - high noise level from external influences. Therefore, special attention is paid to noise insulation:

-

All elements of the structure are fixed by screws. The connected parts reliably tighten them together to prevent the formation of gaps and backlash;

-

The position of the sheathing elements is calculated so that the edges of the sheet of roofing material are located on the carrier rail;

-

Installation of all the elements of the batten and counter-lattice is carried out without deviations from the working plane, as even as possible, without hillocks and cavities. This will avoid distortions in the installation of metal.

The noise level significantly reduces the use of fibrous insulation materials. Some manufacturers produce specialized brands of insulation with a high sound absorption coefficient, from 0.5 to 0.8.

It can be interesting! In the article on the following link read about country house from SIP panels - comfort and coziness at an affordable price .

It is advisable to carry out special vibration isolation measures if the house is located close to the railway, a highway with heavy traffic or if the roof slopes have a large area. For this purpose, special damping pads divide the layers of the roof under the metal tile between the counter-grille bars and the rafter beams.

In the video you can see the installation rules for the roofing pie:

Roofing

High-quality metal tile has a thickness of 0.4-0 , 6 mm and several layers of protection. Visually, the presence of internal protective interlayers is almost impossible to check, so when purchasing roofing materials, ask the seller for a certificate. To protect against corrosion, the metal tile is painted on the inside, and on the outside it has a polymer coating, which is much better resistant to external influence than paints and varnishes. The type of outer protective layer depends on the durability of operation and the cost of the roof. The most common are the following types of polymer coatings:

-

Polyester . The thickness of the protective layer 25-30 microns. Has an affordable cost and relatively high performance. The warranty period of operation of metal tiles with polyester coating is 8-10 years;

-

Polyurethane . It is characterized by resistance to mechanical damage, temperature changes and various chemicals. When bending a sheet, such a coating does not lose its integrity;

-

Polyvinyl chloride . It exhibits high resistance to mechanical, chemical and thermal stress. It has high plasticity. Metal roofing with such a coating is recommended for laying on relief surfaces. It is advisable to apply in regions with extremely hot climates;

-

Plastisol . Consists of polyvinyl chloride with the addition of a plasticizer. It is applied with a layer up to 200 microns, which allows you to apply a relief pattern on the surface of the metal tile. They have low resistance to high temperatures, which does not allow its use in regions with hot climates.

Interior finish

Between vapor barrier a membrane and sheets of drywall or OSB also form a ventilation gap. For this, wooden slats with a section of 20x30 mm are used. attached to rafters perpendicular.

From the video you can learn how to properly make a roofing pie under the metal tile:

It might be interesting! In the article on the following link read about the project of a house with a wavy roof .

Conclusion

Despite the high cost of materials and considerable labor costs when building a roofing pie for a metal roof, it is not recommended to “simplify” the technology by skipping layers or using cheap insulating membranes of unknown manufacturers. The consequences can be the saddest until the complete replacement of the roof.