A warm roof is a requirement of modern construction of private, public and industrial buildings. Energy savings, the price of which increases from year to year, is an important component of government programs that form the social package. Therefore, in this article we will talk about the insulation of the roof from the inside of the mineral wool. We will tell you how to do this, what materials are used other than mineral wool. And also draw your attention to the important nuances of the installation process.

Characteristics of mineral wool

Let's start with the characteristics of this insulation, which will show why he is so popular today.

-

The thermal conductivity of mineral wool is 0.034-0.04 W / m K . To get at least some idea, how good it is, we denote the thermal conductivity of a conventional ceramic brick, which is equal to 0.56 W / m K. This is more than ten times better.

-

The density of mineral wool varies from 30 to 200 kg / m³ . In this case, the higher the density, the higher the mass of the product, the higher the thermal conductivity and the price of the material. For roof structures there is no need to use very dense plates that can withstand heavy loads. Here inexpensive panels with a density of not more than 60 kg / m³ will do.

-

Permeability is 0.49-0.6 . That is, this insulation has a good indicator, which allows air to freely pass through the insulating layer, performing air exchange inside the premises.

-

Minvat is a non-combustible material , which is very important for roofs made of lumber. Today, more and more often there are requirements for building structures relating to increase fire resistance.

The only minus of mineral wool is its hygroscopicity. That is, the insulation absorbs moisture, losing thermal properties. Today, this problem is solved quite simply - by laying protective films of polymers that do not allow moisture to enter the zone of the insulating cake.

Types of insulated roofs

The main task, set by the topic of the article, is to deal with thermal insulation processes that are carried out from the inside. With warming of pitched roofs of mineral wool everything is clear. We will talk about this below. Now consider the option of warming the flat roof from the interior. Although optimal - external insulation. It is easier to work, more convenient and more accurate according to construction canons.

But sometimes, for example, if it is necessary to warm the garage, the insulating measures of a flat roof are carried out from the inside. How to do it.

Warming from the inside of a flat roof

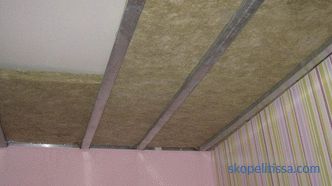

If the roof of the same garage is reinforced concrete slabs, purchased at the factory of concrete products, or a cast-in monolithic plate with reinforcement, in either case, that is, on the ceiling, to assemble a frame structure.

But before that, it is recommended to repair the concrete ceiling: seal the seams with repair mortar or putty, treat with primer deep penetration. This is done so that the material of the concrete pavement, which is formed during the intensive operation of a garage or other structure, does not crumble on the heat-insulating cake. And in the end to process the ceiling surface with liquid waterproofing material. It can be bitumen or polymer-bitumen mastic.

So, the concrete ceiling is ready, now you need to install a frame on it. Its elements are either wooden blocks with a maximum section of 50x50 mm, or galvanized profiles, which are used for the installation of gypsum boards. If the decision is made to use lumber, then it is recommended to treat it with antiseptic and fire retardant before installation. In that order.

But, as practice shows, craftsmen more often use metal profiles. They serve longer, under the influence of changes in humidity and temperature do not change their size, do not warp and do not rot. They are installed on direct suspensions. They do it like this:

-

Several parallel lines are applied on the ceiling in increments of 50-60 cm .

-

On them, starting from any wall, they mount direct suspensions on metal dowels to the ceiling. The installation step depends on what kind of finishing ceiling material will be used for cladding the ceiling. The larger the facing mass, the smaller the installation step of the suspensions. Average pitch: 30-50 cm.

-

First two extreme profiles are suspended.At first, they hang one, exposing it horizontally and fixing it to the suspensions with small self-tapping screws (bugs). Then install the second, aligning not only horizon, but in the same plane with the first.

-

Between the mounted profiles they pull several durable threads that form a single plane of the new ceiling.

-

The intermediate elements of the ceiling lath are installed on these threads.

On our website you can familiarize yourself with the most popular wooden projects houses from double timber and other buildings (bathhouses, gazebos, garages) for country houses - from the manufacturers represented at the exhibition "Low-Rise Country". The filters set the necessary parameters and calculate the cost, depending on the technology, materials, total area and other indicators.

The frame is ready, you can proceed to the laying of thermal insulation material. To do this, you can use mats or roll modification. Insulation simply lay under the frame on which he will rely. The thickness of the heat insulation layer is determined by the distance between the batten and the base ceiling surface. The main task of the producer of the work is not to lower it so that the laying is carried out with gaps between adjacent parts of the insulation, which will later become cold bridges.

Therefore, it is necessary to lay the material in such a way that the adjacent parts fit snugly together. It is better if the installation of mineral wool layers. At the same time observe one important nuance - the junction of two adjacent mat must be closed with mats of the lower layer. That is, the installation is carried out in a checkerboard pattern. The last stage in the process of warming is to lay a waterproofing film over the thermal insulation.

Today, the frameless variant of thermal insulation of concrete ceilings with mineral wool is often used today. The latter are mineral wool pressed into slabs of a certain thickness. These are more rigid products with low hygroscopicity.

Installation is carried out on the ceiling using two types of fasteners. This is either a special mushroom-type self-tapping screw made of plastic, or an ordinary metal screw that is screwed into a plastic dowel inserted into the ceiling surface. But in order for the screw to hold the stove, in addition, between its cap and insulation, a wide plastic washer is installed, which is called a rondol. Washer diameter - 60 mm.

The installation process itself is quite simple.

-

A mineral wool slab is applied to the ceiling.

-

Through it, a drill or a perforator with a long drill makes holes both in the insulation material itself and in the ceiling.

-

Plastic dowels are driven into them if mushroom-shaped screws are used. If a steel screw with a gondola is used, the slab is removed, and plastic dowels are inserted into the holes.

-

Then hold the plate to the ceiling .

-

And in this way all mineral wool panels are mounted. The main task - to install them tightly to each other.

On our site you can find contacts of construction companies which offer the service of repair of the roof, insulation of country houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Usually, the frameless version of the insulation of a concrete ceiling from the inside is used in the event that the ceiling construction is plastered. To do this, the insulation is closed with a waterproofing membrane, a plaster grid is installed, and then a plaster layer is applied. If plates with a high density (more than 125 kg / m³) were used, then waterproofing can be avoided.

The video shows how to warm a concrete ceiling with mineral wool slabs in a frameless way:

This could be interesting ! In the article on the following link read about the cost of roof insulation work from the inside of the mineral wool - price per m² in Moscow.

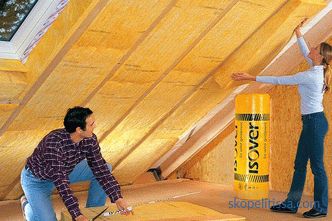

Thermal insulation of pitched roofing structures

It should be noted that the insulation technology of the roof of the mineral wool, meaning the pitched, is a tab of the heat-insulating material between the truss legs. Of course, as in the previous version, it is necessary to close the mineral wool on both sides with protective films.

So, the roof from the inside of the attic or attic room is a truss system over which the batten is installed, and the roofing material is fixed on it. Such roofs are called cold. To make them warm, it is necessary:

-

Strips , starting from the bottom of the roofing structure, put vapor barrier material .His task is not to miss the moisture from the side of the roofing in case of leakage. And at the same time it will let through wet vapors, which can penetrate into the heat insulation layer from the attic. The strips are overlapped (10-15 cm), the joints are closed with adhesive tape.

-

Spend mounting heat insulation material . Its thickness should be equal to the width of the rafters. If the selected material does not have sufficient thickness, then it is laid in several layers in a staggered manner, as was described in the previous case.

-

waterproofing membrane , which is attached to them with a stapler and steel brackets. Installation is carried out in the same way as the vapor barrier material, i.e., overlapped with sticky tape .

-

Further, finishing of the truss system with sheet, plate or panel materials is carried out. For example, it could be plywood, drywall, OSB, chipboard and others.

At this point, we can assume that the insulation of the roof with mineral wool is complete.

The video shows how to conduct the process of warming the pitched roof with mineral wool from the attic:

It can to be interesting! In the article on the following link, read about how to properly arrange large buildings on the site: documents for registration.

There is one more variant of roof insulation from the inside, when there is a task to replace the roof covering. In this case, it is better to approach the solution of some operations differently. That is, from the outside, the roof construction is the rafter legs, on which the crate is stuffed. Since the roofing material is changed to a new one, it is necessary to examine the entire roof system to determine the defective elements. And, if they are found, they should be replaced.

Now a vapor barrier film is installed over the rafter legs: from the bottom up, overlapping with the use of adhesive tape. Next, the rails are laid on wooden slats with a section of 50x50 mm, which are attached to the rafters with 70-100 mm long screws. This is a counter grill that will create a ventilated gap between the thermal insulation cake and the roof covering. Now across the truss system they fill the crate, and already above they install the roofing material.

As for the insulation of the pitched roof, this operation is carried out from inside the roof. That is, between the truss legs, the mineral wool is laid, and a waterproofing membrane is stuffed on top of it. That is, everything is exactly the same as in the previous version.

Useful tips

Roof insulation - the process responsible. It is impossible to allow all kinds of assumptions For example, you can not use high-density insulation, because it has a lot of weight, which will require additional strengthening of the truss system. In addition, the high density of mineral wool is a high thermal conductivity of the material, which should not be allowed.

Do not install, leaving gaps and cracks. And although this problem is now solved simply - filling defects with foamed sealant, all the same, the less materials are used, the better.

Mandatory operation is the processing of sawn timber used in the roofing structure with antiseptic and flame retardant fluids.

When installing a roofing material, it is necessary to leave a ventilation gap in the roof ridge structure through which moisture will be removed from under the roofing material.

The video shows a model of a sloping roof on which the insulation is carried out with mineral wool from the inside:

This could be interesting! In the article on the following link, read the article "I sit high - I look far: a house with transparent walls on the rocky shores in Norway."

Conclusion on the topic

Warming of the roofs from the inside with the use of mineral wool is the most frequently used option in private housing construction. Minvat is an inexpensive material, with good thermal performance, it is convenient to lay it between the truss legs without additional fastening, the service life is quite long - up to 50 years if the entire installation process is carried out correctly.