Today we will talk about such a necessary room, like a basement in a garage. For what purposes it can be used, everyone decides for himself, and we will designate the main points and nuances of its construction. Having understood the information received, you will understand what the masters are doing. In addition, you can ask intelligent questions about the construction of the basement and the technology of its construction.

basement in the garage t70215-01

basement in the garage t70215-01

Step by step instruction of the construction of the cellar

It is necessary to indicate that The cellar in the garage is a complete building with a floor, walls and a ceiling. You can build it at the stage of building a garage or in an already operated room. Depending on the situation and construction technology will be different.

The facility filed in the garage under construction

This is an economical option, because the foundation of the garage will serve as the walls of the cellar. Therefore, in the first place on the site marking is applied under the garage structure. At the corners of the building pegs are hammered, which are tied with twine. Here we must take into account the fact that the external sides of the foundation structure must be waterproofed. Therefore, the excavation is dug 1 m more on the side of the length and width of the garage. For example, if the parameters of construction are 3x6 m, then the pit should be 4x7 m. That is, there is half a meter on each side, which is enough for waterproofing works.

The next stage is earthworks. In this case, you can use heavy equipment in the form of an excavator. The absence of the walls of the building allows it. The main thing after working the equipment is to work the bottom and walls of the pit with shovels. What should do the workers. The bottom line as much as possible on the horizon, the walls vertically.

A few words about the depth of the basement. Everything will depend on the depth of the groundwater at the construction site. Lowering is not recommended. If the depth of groundwater is high, you will have to carry out complex waterproofing. And this is a big cash investment. The second option is to raise the floor base and make the entrance to the garage under the slope.

Basement bottom

So, further down the construction technology filed in the garage.

-

A cushion of 30 cm thick sand layer is deposited on the bottom, a layer of crushed stone 10-15 cm thick.

-

The ruberoid is laid in two layers. Each layer in perpendicular directions. For example, the lower along the building, the upper across. The layers of roofing material between them are impregnated with bitumen mastic or hot bitumen.

-

Pour a concrete screed.

It is necessary to tell a little bit more about the screed. Pure concrete is not used here. Under the action of loads, it will crack. Therefore, a reinforcing frame made of steel reinforcement with a diameter of 10-12 mm is laid inside the screed. The reinforcement rods are assembled directly on the ruberoid in the form of a lattice with cells of 20x20 cm. They are tied together with a knitting wire. Then the grid is lifted and placed on supports made of brick or metal profile (angle, pipes, etc.). According to the technology, the armature frame should be inside the concrete basement basement.

Pour the concrete solution. Its thickness is in the range of 10–20 cm.

On our site you can familiarize yourself with the most popular projects of garages and other small forms for a country house - from construction companies represented at the exhibition "Low-Rise Country".

Foundation Construction

The next stage is the construction of the foundation. Now everything will depend on what he is going to. The easiest way to use a prefabricated structure of foundation blocks, concrete wall blocks or bricks. Monolithic construction is stronger, but their construction is expensive. In addition, it will take a lot of time, and this option is more difficult in terms of labor costs. Because in order to fill a concrete solution, it is necessary to build a formwork, install reinforced frameworks in it, pour concrete into the concrete, and then wait 28 days for the solution to pick up its brand strength.

With regard to block blocks or bricks, the main task of the producer is laying with a band when the elements of the upper row are laid with half a block offset relative to the elements of the first row.

Floor construction

Once the foundation has been raised to the height of the cellar, you need to think how the ceiling will be constructed. The easiest option is to lay six hollow-core slabs. By the way, in typical projects of a garage with a basement, this option is used. Therefore it is not necessary to invent a new design of the bike. Use the plates. However, for their installation will have to use the services of a crane, which will increase the cost of construction. But prefabricated slabs are a quick and reliable way. Moreover, manufacturers offer products with a minimum length of 3 m.So, it is not difficult to choose the required model, which will lay exactly on the basement walls.

A more complex variant is a monolithic slab. The technology of its construction is similar to the construction of a monolithic strip foundation. Under the slab collect formwork. In fact, these are sheet durable materials (corrugated board, plywood, OSB slabs, sheet iron, etc.), which are placed on the walls of the foundation with edges, and evenly set supports with lags (transverse or longitudinal) under them. After that, a box is assembled from the boards, which will form the fill thickness. Its size is equal to the size of the foundation.

-

The box is placed on the constructed base.

-

A reinforcing framework made of reinforcement is placed inside.

-

Pour concrete solution at the level of the box.

-

After 7 days, the box is taken apart, after 28 days the floor can be operated.

A few recommendations: the thickness of the monolithic floor slab is not less than 15 cm, the diameter of the reinforcement used is within 10-12 mm.

On our website you can find contacts of construction companies that offer the service of designing and building garages and other small forms for a turnkey country house. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Please note that when constructing a ceiling, care must be taken to ensure that there remains an opening for descending into the basement. When casting a monolithic structure inside the box in the required place is placed another rectangular box of smaller size, corresponding to the size of the opening. Its inside is not poured with concrete. After removing the formwork in the laid sheet materials cut out the opening, the ends of which are subsequently fixed, for example, with a bandage from a metal corner.

When using pre-fabricated floor slabs, one of them is not installed in the basement opening area. Here, a monolithic structure is poured with the installation of the formwork and the formation of the opening.

Stages of building a basement in a garage in the video:

External waterproofing of the foundation

This is the simplest stage. Basement walls are treated with bitumen mastic or hot bitumen. The main thing - do not miss more than one site. Processing is carried out evenly, preferably in two layers. After drying the waterproofing, the ditch between the foundation and the ground is filled up.

Basement construction in the operated garage

The complexity of this technology lies in the fact that the garage foundation laid at a shallow depth, as the building belongs to the category of "light". Therefore, digging the pit for the basement must be done carefully so that the walls of the foundation do not collapse and the garage itself does not work.

If the soil under the garage is clay, then you can safely drip the pit, stepping back from the walls of 30-50 cm. If the soil is sandy, then the digging technology will be completely different.

-

Along the far short wall, half a meter back, dig a trench with shovels to the depth of the cellar. The trench width is 0.5 m.

-

The pillow is filled up and the screed is poured.

-

Raise the basement wall of concrete blocks or bricks.

-

They dig a trench near the long longitudinal wall of the garage.

-

Fall asleep pillow, pour the screed and raise the wall.

-

The same is done with the opposite wall.

-

Last is the construction of the wall closest to the entrance.

-

The soil remaining inside the basement walls is selected.

It remains only to level the bottom of the pit, pouring a pillow into it and filling the screed.

It might be interesting! In the article on the following link read about frame garages projects.

Basement Waterproofing

In this case, internal waterproofing is used. First of all, two layers of roofing material are laid on the floor with approaching walls to a height of 20-30 cm. Laying layers are mutually perpendicular. You can use polymer mastic, which is applied in a seamless way. The main task is to close the joints between the walls of the cellar and the floor base, because these are the weakest points in terms of moisture penetration.

As for the waterproofing of basement walls, it is most often used for this purpose roofing material laid on bitumen mastic. Use today polymeric compositions. The old way to finish the basement garage - lime plaster, brick.

Overlap filed

In this variant of the organization of the basement, the technology of monolithic fill of the ceiling is used. About it was told above, so it will not be repeated. Just add that the overlap is poured from wall to wall of the garage basement. Accordingly, the reinforcing frame is collected specifically for these dimensions.

Ventilation of the basement in the garage

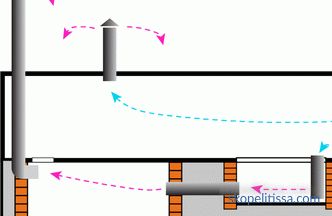

As with any basement, the garage must be dry. So, it is necessary to provide a ventilation system in it. The basic principle of operation of this system is the supply of fresh air from the outside and the discharge of settled air to the outside. Therefore, it is necessary in the process of construction of the cellar to install two pipes. One near the entrance, the second from the opposite side.

The structure in the garage basement of the ventilation in the video:

The first one, since it is located closer to the exit to the street, will perform the functions of a supply circuit from the outside. The pipe should stick out 5 cm above the floor in the garage and sink to the floor in the basement, not reaching it 5 cm.

The second one will serve to exhaust air from the basement. Therefore, it leads through the garage room and the roof. In this case, the lower end of the ventilation pipe should be located under the cellar ceiling (5 cm below its surface).

It turns out that outside air will flow into the basement near its floor, and then move diagonally through the room to the exhaust pipe. Thus, the entire air mass is covered.

It might be interesting! In the article the following link read about lifting gates for the garage.

Ready basement structures

All the above works are complex and cost a lot of money. Today you can buy a finished plastic cellar in the garage. It is made of low pressure polyethylene or polypropylene. Method of production: welding of individual elements or molding of finished cellars.

The advantages of plastic constructions are obvious:

-

complete tightness, which guarantees protection of the internal space from the penetration of moisture or groundwater;

-

wide model range allows you to fit the size of the garage;

-

easy to install - one day is required along with digging the excavation;

-

ease of construction does not require the presence of the construction site of heavy machinery;

-

high strength of the structure;

-

full set in terms of hatch and ventilation;

-

reasonable price, to pr The plastic cellar, made in a welded way, with dimensions of 1.6x1.6x2.4 m costs 100,000 rubles.

Basement with observation pit

Inspection pit in garage - object necessary than the basement. Therefore, many owners are trying to give preference to the pit. But there are projects of garages with basements and inspection pits. If the right approach to solving some issues, then in the garage you can get in the presence of one and the other.

Note the photo below. Here you can clearly see how you can combine both elements in one garage. This is the best option where the entrance to the cellar is formed from a viewing pit. But you must first decide on the size of the basement. The same photo shows that the cellar occupies the area closer to the far wall of the garage building.

With regard to construction, in this case use the same technology described above. Only the ceiling is poured monolith.

It might be interesting! In the article the following link read about prefabricated buildings Ten Fold Engineering, which are decomposed in 8 minutes.

Conclusion on the topic

A variety of technologies for building a basement in the garage makes it possible to choose an acceptable option. But do not reduce the cost of the project. And even less to avoid some of the technological nuances. Special attention to waterproofing, because poorly performed work is a guarantee that water will appear in the basement. Want to get high quality at an affordable price - choose a plastic cellar.