This article contains information about the wind strip for a soft roof - what it is, what it is for, types and sizes, with what details it should be combined. A detailed description of the characteristics of various protective coatings will help you choose a quality durable product. You will also learn about the technology of installing the slats, which will give a general idea of the rules of installation.

Soft roof and additional elements for it

Soft roof is a roof covering made from fiberglass impregnated with bitumen with a modifier and coated with shale, basalt crumb or copper tape. Other names are shingles, shingles, shingles, shinglas, roofing tiles, shingles. This material is sold in the form of pieces of rectangular, square, hexagonal shape, with figured cuts (diamonds, scales, etc.).

To extend the service life of the roof, to give a complete appearance, along with flexible tiles, special additional elements are necessary - skates, endy, snow guards, aerators, angles. All parts are selected according to the color of the selected roofing tiles. Skates and end carpets are made of the same material as the shinglas, or similar. The remaining additional elements can not be made from a soft bitumen coating. The slats are made of steel roofing with a protective anti-corrosion and polymer coating.

Types of roofing strips:

-

curtain rail for a soft roof (drip);

-

wind strip —other names: front, front, front, front apron, wind corner ;

-

junction bar for a soft roof - it may not be included in the package, instead of it, they often use a velter carpet.

To get the best result, it is recommended to buy all the additional elements from one manufacturer.

What is the wind strip

The end strip for a soft roof is a strip in the shape of the letter “G” with a bend at an angle of 45 ° (barrier). It is installed on the gables to seal the ends of the roof (hence the name).

Wind strip functions:

-

protection of the roofing material from being torn down or damaged by strong gusts of wind;

-

warning of precipitation , dust and cold air under the coating and crate;

-

improving the reliability of hydro and thermal insulation of the roof;

-

removal of precipitation from the cornice filing.

There are two types of pediment gables for a flexible roof:

-

simple - with a bend of the edge (stiffener) only on one side;

-

with double rolling - with bends on both sides, two stiffeners increase corner strength, therefore this option is preferable.

Sizes of wind slats for a soft roof:

-

the width of the upper flange is 100, 130, 80, 60 mm, this part of the corner should go under the roof covering of at least 50 mm;

-

height of the barrier - 20, 25, 30 mm;

-

overhang height - 70, 80, 90 or 100 mm, this part of the plank must completely cover the frontal plank;

-

stiffener on the overhang - 10, 15 mm;

-

fin stiffness on the upper shelf (only at the corners with double rolling) - 10 mm.

In addition to the above, other options are possible. If necessary, additional manufacturers can order additional parts according to individual sizes. The price of the curtain rail for a soft roof or a wind corner made to order will be 50 - 100% higher.

The standard length of the end plate for shingles: 500, 750, 800, 1200, 1250, 1500, 2000, 2500, 3000 mm. When calculating the required amount of material must be borne in mind that the useful length is less than the actual. This is due to the fact that when installing the corners are connected with an overlap, with an overlap of at least 10 cm.

Sheet characteristics steel for wind strips to shingles

The thickness of the sheet of roofing steel from which the end strips are made is 0.4; 0.45; 0.5 or 0.7 mm. The thickness of the protective layer responsible for corrosion resistance (galvanized) is from 100 to 275 g / m². It is indicated in the product marking after the letters indicating the type of protective metallic coating. For example, the code Zn 265 means that the steel is covered with a layer of zinc with a thickness of 265 g / m². The higher this indicator, the better - it affects the service life of the product.

Types of protective metal anti-corrosion coatings for roofing steel:

-

zinc (Zn) - consists entirely of zinc;

-

zinc-aluminum (ZA, Galfan, Galfan) - an alloy of zinc and about 5% aluminum, corrosion resistance 2.5 times higher;

-

aluzinc (AZ, Aluzinc) - 55% aluminum, 43.4% zinc and 1.6% silicon, corrosion resistance is 10 times higher than with ordinary galvanizing, silicon increases the heat resistance of the material.

Types of color coatings

A color polymer coating on a wind strip can be applied only on the front side or on both sides. The second option is a bit more expensive, but you should prefer it if you want to achieve the perfect result in terms of beauty and accuracy of the roof design.

On our site you can familiarize yourself with the most popular suburban areas in the Moscow Region home . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

The surface of the polymer coating can be:

-

smooth matte or shiny (glossy) - steel silk, satin, satin, etc., matte coatings are usually more resistant;

-

textured (with different effects) - steel velvet, drape, velor, etc.

Polymers that make up the protective and decorative coatings of wind strips for soft roofs:

-

polyester - a guarantee of corrosion pass through from 10 years, the appearance from 5 years;

-

polyurethane , modified by polyamide granules (pural) - costs approximately d a times more expensive than polyester, a guarantee for penetrating corrosion from 30 to 50 years, the appearance from 15 to 35 years;

-

plastisol (polyvinyl chloride, PVC) - by the main indicators are approximately on the same level with the pural, it is superior in strength, the layer thickness is 200 microns, the surface is textured, imitates the bark of the tree.

What to look for when choosing

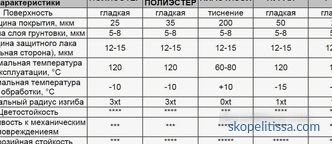

Polymer coating characteristics that you should pay attention to when choosing refractory roofing elements:

-

polymer layer thickness (in microns) - not less than 25, the larger the better, but it must also be borne in mind that 25 microns of Pural is more reliable than 30 microns of polyester;

-

resistance to UV (according to standard EN 10169) is marked RUV code with a digit from 1 to 5 is the best indicator RUV 5, for the Russian Federation and Belarus sufficient level level RUV3;

-

strength at reverse blow (J) - from 10 to 18, the more, the better the coating withstands mechanical stress;

-

hardness - ability to resist scratching and abrasion, has value during transportation, installation, is determined by the pencil method (the best indicator is 2H, worst F);

-

anti-corrosion resistance - determined by testing in water and salt fog, best indicators: 1500 hours for water fog, excellent for salt (see in product description);

-

adhesion - firmly The degree of adhesion of the coating to steel, is important when cutting strips into pieces of the desired length, the best indicator is 0.

On our website you can find contacts of construction companies that offer services for designing and repairing roofing . Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

How to install the wind strip on a soft roof

The basic rules for mounting the end plate for shingles:

-

The front corner is set to installation of a soft roof, after laying the lining carpet. Tiles are laid on top of fixed planks covered with a layer of roofing bitumen mastic.

-

The installation of the wind bar starts from the bottom, moving towards the ridge.

-

For fixing the corners use special roofing nails or colored roofing screws with sealing rubber rings. The crate for flexible tiles is made only of wood or materials based on it (plywood, OSB-plate). Therefore, the fasteners must be on wood, not metal.

-

Nails and self-tapping screws are arranged in 12 - 15 cm increments in a checkerboard pattern.

-

In order for to avoid the appearance of waves on the surface of the fixed strips, proceed as follows. First, two nails are driven in along the edges of the additional element, but not completely, but so that they can be easily pulled out. This is necessary for temporary fixation of the part. Then completely hammer several nails in a row, moving in one direction.After that, take out the fasteners installed at the ends of the plank, and drive in the remaining nails.

How to cut wind strips

For cutting roofing slats are not suitable for any tools - there is a high risk of damaging the protective coating, which will lead to rapid destruction of the material. Important conditions:

-

in the process of doing work no sparks should appear - they can get on the polymer layer and damage the coating;

-

Invalid strong heating when cutting (which is inevitable when using the grinder) - both steel and protective layer melt.

List of suitable tools:

-

disk power saw;

-

manual hacksaw for metal;

-

jigsaw;

-

metal shears manual or electric;

-

drill with special cricket attachment.

If installers use other tools, special attention should be paid to the issue of compliance with the warranty. The guarantee should not just be spelled out in the contract - it is necessary that the responsible person is clearly indicated, plus the contacts of the company are given. If this minimum is not, then there is a chance that there will simply be no one to demand the fulfillment of the guarantee obligations.

In the video you can see the wind strip installation:

It might be interesting! In the article on the following link read about House project with a wavy roof .

Conclusion

Wind strip is an essential element of a roof construction. The correct choice of material and proper installation of this element will protect the roof from sudden gusts of wind and prevent "blowing out" of moisture under the roofing pie, therefore, the best solution would be to entrust roofing work to professionals.