The boom of country construction has led to the fact that few places remain available for a full-fledged residence. But regional authorities distribute plots to everyone, even in areas with a high level of groundwater (technical abbreviation - GWL). That is, in the rainy season or melting snow, areas are covered with puddles that do not dry out for a long time. Green areas grow poorly in such areas, and construction is not easy. Only one way out - to lay the drainage system, which consists of different elements. In this article we will talk about the well drainage viewing. That is: what it is, what materials it is made of, sizes, design features, as well as the method of installation.

Types of inspection wells

To begin with, the well used in the drainage system of the drainage system performs only two functions:

-

Through it control the quality drainage state .

-

Spend cleaning the system .

As for the shape, the wells on the market are represented by round and rectangular devices. They can be installed in the drainage of pressure and free-flow design. But there are some subtleties of installation in each individual case.

The two systems differ from each other in that the pressureless is a gravity flow system in which water moves under the force of gravity. Pressure is a system that includes pumping equipment. That it pumps the groundwater. In suburban construction is most often used first.

In essence, these are several straight pipe sections connected in one common system. The latter can be very difficult, so it is impossible to do without inspection wells. Therefore, they must be installed in the following cases:

-

on straight sections ;

-

at the point of contour connection or their forks ;

-

in the place of the change in the diameter of the pipe layout;

-

in the point where the inclination of laid drainage pipes begins;

-

at the site where changes direction groundwater movement.

It should be noted that on straight sections there are inspection wells at a certain distance from each other, taking into account the diameter of the pipes used. Here the dependence is this:

| Diameter of drainage pipes, mm | Distance between manholes, m |

| to 150 | 35 |

| 200-450 | 50 |

| 500 -600 | 75 |

| 700-900 | 100 |

| 1000-1400 | 150 |

| 1500-2000 | 200 |

| more than 2000 | 250 -300 |

It should be noted that all these indicators are recorded in SNiP 2. 0403-85 under the name: "Sewerage. External networks and facilities".

As regards the size of the manholes themselves, they are presented on the market in standard size. And pick up their diameter under the diameter of the pipes of the drainage system. The dependency is shown in the lower table.

| Diameter of the drainage pipe, mm | Diameter of manhole, mm |

| 100 | 600 |

| 125 | 700 |

| 150 | 800-1000 |

| 200 | 1200 |

If the manhole is installed at the place of rotation of the system, then its diameter should be increased, because the movement of water in it will slow down. That is, there will be accumulation of fluid that will fill the well. At the same time, it is in such places that the quick silting occurs.

It is also necessary to consider the depth of the wells when selecting. The thing is that cleaning and repair work through them is not so easy. And if the depth is large, then the worker will need to go down into the well for repairs. Therefore, if the depth of the burial, which means the length of the well, does not exceed 1.2 m, then devices with a diameter of up to 700 mm can be used. If the depth is over 2 m, then at least 1500 mm.

It is necessary to add that devices with a small penetration rate are called inspection ones. Deep are called serviced. Note that wells with a diameter of more than 700 mm are completed with ladders or brackets for comfortable descent inside.

Types of viewing wells for the drainage system

There are only three types:

-

linear ;

-

rotatable ;

-

node .

The latter are devices into which several drainage circuits are connected. They are set in such a way that the minor contours approach the main point at an acute angle.

On our website you can familiarize with the most popular projects of small forms - bathhouses , gazebos , garages of any category and construction technology - from construction companies represented at the exhibition "Low-Rise Country".

Production materials

Today, manufacturers offer inspection and storage drainage wells of three materials: concrete, plastic and composite. Concrete products (reinforced) have rather serious strength characteristics:

-

well resist strength buoyant water ;

-

they easily withstand serious loads ;

-

low price.

One disadvantage is a large proportion. Often for their installation use the services of lifting mechanisms. So, it is necessary to organize an access road if the crane is used, for example. Some manufacturers produce wells without through holes for pipes. Therefore, they have to drill in place, which is not so simple. And one more small minus - concrete is not one hundred percent waterproof.

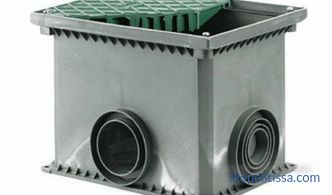

In this regard, polymer wells and made of composite materials are better. They are lighter, they are several times smaller, they have one hundred percent waterproof. But the size of the device is small - does not exceed 400 mm. But, as practice shows, this is enough when building a drainage system on a country site.

It is necessary to add that plastic products are gradually replacing all others. There are several reasons for this:

-

small specific weight ;

-

100% tightness ;

-

large variety shaped parts ;

-

speed and simplicity mounting .

But it is necessary to take into account the moment that the carrying capacity of plastic devices is not the highest. In any case, according to this characteristic, they lose both concrete and composite products. Therefore, when the task is to install the inspection wells for drainage from drains that are installed near the roadway, then you should pay attention to the thickness of their walls. What it is, the better.

The video shows manholes for the drainage system of plastic, made in linear and rotary design:

On our site you can find building contacts companies that own a full cycle of own production provide a water supply and sewage service . Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Installation technology of the inspection well

In principle, inspection wells are installed during the assembly of the entire drainage system. And for this it is necessary to dig trenches into which drainage pipes will be laid, to decide on the installation sites of the wells: inspection and accumulative.

Then begin the installation of pipes. Usually start from the basement of the house, moving to the cumulative well, which is installed in the lowest place in the suburban area. The pipes are brought to the installation sites of the viewing devices, where the latter are mounted. It is clear that in such places do extensions for convenient carrying out the required work.

They try to install the drainage system during the period when the groundwater level is lower. But even during this period water may appear in trenches and pits. Moreover, the pit under the manhole is usually dug below the trenches for pipes to a depth of 30-40 cm.

The bottom of the pit is covered with sand 10 cm thick, which is tamped. And after that install the well itself. It is connected to the drainage pipes, the joint of the connection must be sealed.

This may be interesting! In the article on the following link, read about drainage well .

With concrete products, more difficulty. First, you need to create a solid foundation for them. Therefore, the bottom of the pit is flattened with a layer of sand that is being tamped. Next, collect the reinforcing frame of steel bars in the form of a lattice. It is placed on bricks or stones, which are pre-installed on the sandy bottom. Then pour the concrete solution.Today, many manufacturers of concrete products offer ready bottoms. They are simply lowered to the bottom of the excavated trench, which is pre-leveled. Here the task of the masters is to conduct a good sealing of the joint between the bottom and the well to be installed.

Concrete wells must be sealed tightly, so they install covers from the same concrete solution, which have an entrance hatch. In this regard, plastic products are better and easier to use. This is usually a pipe, which consists of two roofs: the lower and upper. The first is a tank, which is put on the pipe. She rests her plane into the bottom of the pit. The second cover closes the well from above. Today, manufacturers offer plastic devices with the bottom cap already attached. That is, the well is a one-piece design, with one top lid as a separate element.

This may be interesting! In the article on the following link, read about a winter garden to make your dreams come true: Japanese mini-gardens in your home - beauty for yourself and friends .

And one more thing. Plastic - a material that does not rot, does not rust, does not interact with many chemically active substances. Concrete cannot boast such characteristics. Therefore, if you chose a concrete well, then his masters must necessarily waterproof, preferably from two sides. Usually today they use bitumen mastic, which is applied in two layers.

So, the inspection pit is installed and connected to the pipes. It remains to hold it backfill. If a concrete structure was installed, then there are no problems. The pit is just covered with soil. If you used a plastic device, it is recommended to make the filling with sand, it can be interspersed with the ground. Usually, a layer-by-layer tamper is carried out taking into account the layer thickness within 20 cm.

It is very important to set the hatch opening correctly in height.

-

If this is driving part, then the hatch is mounted flush with it.

-

If it is a lawn or a plot of with greenery, then the hatch is set 5-7 cm above the grass .

-

If the drainage is constructed in the undeveloped area , then the manhole should be above the soil , at least 20 cm.

The video shows how to properly insert the drain pipe into the manhole:

This could be interesting! In the article on the following link, read about a bed under the ceiling is a great solution for a mini home in a loft-style .

Conclusion on the topic

In general, there is a special relationship to the manholes. They are rarely used because the drainage system is rarely polluted. But according to the SNiP they must be installed. With proper design and well-performed installation work, drainage is cleaned once every five years. And the very life of the drainage is not measured by one decade.