Today we will talk about the insulation for the attic roof, because this material plays the most important role in the roofing structure itself. After all, the attic building, in fact, serves as walls and roofs at the same time. And since its thickness is insignificant, it means that a sufficiently large amount of thermal insulation work has to be carried out, where great importance is attached to the choice of insulation. If you understand the proposed information, you can easily select the insulating material for the attic of your house. And no one can fool you.

To begin with, the insulating materials on the modern market are represented by a wide range. But the question of what kind of insulation is better for a mansard roof, and today is acute. Experts do not recommend all of the proposed, and not everyone uses, as practice shows. All kinds of mineral wool, polystyrene foam plates (foamed and extruded), polyurethane foam and ecowool are in demand. About them and will talk.

Selection criteria

Today there are a large number of requirements for thermal insulation materials, which, in principle, they must meet. But even the above are not suitable for all required criteria.

So what should pay attention to when choosing insulation:

-

thermal conductivity ;

-

density , on which the thickness of the heater used will depend, here, the denser the material, the less layer it can be laid;

-

low combustibility ;

-

simplicity installation;

-

long-term operation;

-

environmental friendliness , the material should not emit any unpleasant odors and toxic substances.

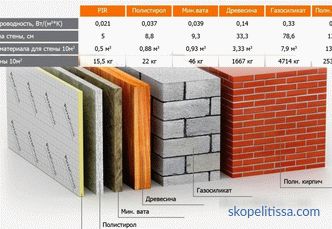

Comparison of insulation according to criteria

For simplicity of perception of information, to make it easier to compare heaters with each other, we summarized the characteristics in a single table for the points.

| Characteristics | Mineral wool | Polystyrene plates | Polyurethane | Ecowool |

| Thermal Conductivity, W / m K | 0.042 | 0.034 | 0.028 | 0.038 |

| Density, kg / m³ | 50-200 | 25-45 | 55 | 40-45 |

| Flammability rating | NG | G3 | G2 | G1 |

| Easy installation | just | just | special equipment is required | special equipment required |

| Service life, year | 50 | 20 | 80 | 100 |

| Environmental friendliness | + | + | + | + |

On our website you can get acquainted with the most popular projects of houses with an attic from construction companies represented at the exhibition "Low-rise A country".

One could add a few purely technical parameters that would reflect the strength of the insulation. But in our case, when the task is to insulate the mansard roof, these figures are not so important, because the material is not subjected to mechanical loads in the roof system.

What can be said by comparing all the parameters with each other. According to the insulating qualities of the best insulation for the roof of the attic - polyurethane foam. And his life is not bad. But this material is a foam consisting of two components that must be pre-mixed in a special container, and then create pressure so that the foam flies out of the tank. That is, to cover the attic roof with polyurethane foam, you need special equipment. And this increases the cost of the work.

At the same time, expanded polystyrene copes with high humidity. In this regard, mineral wool is inferior. But today, to protect against the negative effects of moisture is not difficult. Simply, the insulation from both sides is closed with waterproofing films, and this problem is solved by 100%. Although already on the market you can buy moisture-resistant mineral wool mats.

And a few words about combustibility. Of all four proposed materials, only mineral wool is classified as "non-combustible" because it is made of stone. But at high temperatures, it melts, turning into a viscous mass. The remaining heaters burn to varying degrees at different temperatures. And there is a lot of controversy.

On our site you can find contacts of construction companies that work with credit funds and payment maternal capital. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

There are opponents who categorically refer to everything that burns. They argue that in private housing you need as little as possible to use combustible materials. In some ways they are right. But if you follow their statements, then first of all it is necessary to abandon the roof structure made of lumber. After all, wood is the most combustible building material.

That is, it is impossible to follow this path in construction. It is better to learn the rules of fire safety and strictly observe them. So much for the solution. Moreover, this option is much cheaper than, for example, replacing rafters from beams with steel profiles.

And a few words about ecowool, so that readers have an idea of what it is. This is 100% wood pulp. In structure, it resembles cotton wool, hence, in principle, the name itself. No glue or bonding agents. The only thing that is added to the material is necessarily an antiseptic and fire retardant. The first is protection from pests, the second is to reduce flammability, therefore ecowool is classified as "low-combustible materials".

Insulating Layer Thickness

Since, apart from the thermal insulation material, the attic is from the outside nothing closes in terms of confronting street temperatures, it is very important to choose the thickness of the roof insulation. Of course, everything will depend on the temperature on the streets, on its annual average. Therefore, in the first place, this indicator should be recognized. This is not secret information, it is freely available. For example, the photo below shows a map with a breakdown of winter temperatures by region of Russia.

It might be interesting! Read the article in the following link about the layout of the house 6 to 6 with an attic: photos, projects.

For example, for the middle band of the country it is optimal - the thickness of the mineral wool for the attic insulation: calculated 214 mm, used within 150-200 mm. For polystyrene foam plates - in the range of 120-150 mm, for polyurethane foam - 70-100 mm. Please note that the denser the material, the higher its thermal conductivity, the thicker it will be to form a protective insulating layer.

Rules for laying insulators on the mansard roof

Since all heat-insulating materials have a different shape and structure, their installation methods on mansard roofs will be different. However, it is necessary to designate that mineral wool in mats fits in almost the same way as polystyrene foam plates. Therefore, combine them into one section.

Installation of mineral wool and expanded polystyrene

It is possible to warm the attic of mineral wool or expanded polystyrene either before or after the laying of the roofing material. Consider both options and start from the first.

-

A waterproofing material is placed on top of the truss system . It is laid out in strips across the rafters, starting from the eaves of the roof. The strips are laid overlapped with an offset of 10-20 cm, followed by sealing the joints with a self-adhesive tape. Fixing the film to the rafters is carried out with a stapler and metal clips.

-

Conducting mounting of the grille , crates and roofing material.

-

The remaining processes are transferred to the attic .

-

Between the truss legs lay a heater so that it is tightly pressed against the ends of the rafters. Therefore, the insulating material is cut or selected in thickness so that it is slightly larger than the distance between the rafters.

It might be interesting! In the article on the following link, read about projects of foam concrete blocks with a loft: the advantages of the attic floor, examples of projects, photos.

-

A vapor barrier is installed on the top of the truss system from inside . This is a film material in rolls, like waterproofing. Therefore, the method of its application and mounting is identical to a waterproofing membrane.If you remember, then it was said above that polystyrene foam boards are not afraid of moisture, if they are placed on the attic roof as a heater, then the vapor barrier layer can be not used.

-

Spend lining of the attic from the inside along the rafters, using slab or sheet material: plywood, OSB, chipboard, drywall, wall paneling, etc.

Option two, when the roofing material is already mounted on the roof. This method differs from the previous one only in that the waterproofing layer, like all the other layers of the roofing pie, is placed inside the attic. That is, the rolled material is placed on the rafters without stretching, even with sagging, so that it can be laid between the elements of the truss structure. So that you understand what it is about, look at the photo below.

All other construction operations are carried out using the same technology described for the first option.

Some masters advise against using polystyrene foam for attic. You can evaluate the correctness of the arguments by watching the following video:

Warming the attic with polyurethane foam

In principle, this is the easiest way, because no preparatory work it is not necessary to produce here, except for assembling equipment and filling it with insulation components. The process itself is the application of foam on the inner surfaces of the attic. The only point that must be taken into account is the application of polyurethane on the plane. If the attic crate is discharged, then it is necessary to lay a layer of waterproofing under it, if it is solid, then there is no need to enclose anything.

We offer to watch the video of how polyurethane foam is applied on the inner surfaces of the attic room:

It might be interesting! In the article on the following link read about the projects of houses with a loft.

Warming with ecowool

There are two technologies for applying ecowool: dry and wet. The first is used for warming horizontal structures: floor or ceiling. The second for warming vertical and inclined planes, just for the mansard roof. Although today it is often used and dry version.

The basis of the wet technology is the application of insulation under pressure. Therefore, it is pre-mixed with water and add special glue. Heat insulating mass is applied under pressure on the plane to which it simply sticks. Since this process is difficult to control in thickness, it is not strictly followed. Just after the end of all work, the surplus is cut by a special roller to the level of the outer ends of the rafter legs.

As regards dry technology, for this purpose, strips of vapor barrier film are laid on the rafter legs, as in the case of mineral wool and expanded polystyrene. Then, in the stacked polymer layer, a hole is made into which a loose insulation is pushed out of the hose. The main task of the work producer is to place the material evenly throughout the under-roof space.

About preparing the roof for ecowool weatherization - the following video:

It might be interesting! In the article at the following link read about the birdhouse hut in a Canadian forest.

Conclusion on the topic

So, we told about four heaters for the roof of the attic, which one is better, it is difficult to answer. Each material has its own advantages and disadvantages. But in any case, the prerogative is thermal insulation and environmental friendliness. After all, the insulation is made with one goal - to create conditions under which it will be possible to live in the attic regardless of the temperature outside. And environmental friendliness is the criterion that is responsible for the health and life of people living in the house.