Bath at the dacha is an attribute of comfort and regular rest in a close friendly company. Capital construction of the bath complex takes time, finances and construction materials, so many people prefer to buy a ready-made bath, which can be used immediately after installation.

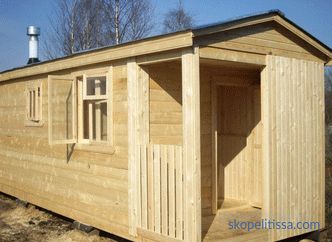

An alternative to traditional projects is quick-build or mobile baths that take up less space as well as ready to use immediately after delivery. Owners of compact suburban areas and a limited budget will appreciate such projects presented in the portfolio of many developers.

Technology of pre-fabricated or mobile baths

Ready-made baths are modest timber structures built at the factory. The craftsmen make the hull of small sizes, according to the client's request, carry out the interior decoration, and then deliver the assembled bath to the installation site.

The owner of the suburban area, with the help of craftsmen, installs the structure on a prepared flat area, installs communications, and after that the bath is immediately ready for operation. Some manufacturers provide complete concrete slabs, on which the entire structure is installed.

The nuances of the technology depend on the specific manufacturer: some offer wiring installation and carry out interior decoration, others leave this question to the client for an independent decision.

The cost of the finished pre-fabricated bath may not always include the installation of the foundation, the installation of the furnace, as well as the cladding of the internal partitions. But on the other hand, it allows you to independently select these design elements and get a bath with minimal financial costs.

Advantages of ready-made baths

The main advantage of such projects is the speed of production. The assembly of the bath complex is carried out in the factory, most companies install furnaces, install electrical wiring, so the customer does not have to search for a team of carpenters and spend money on electrician services.

The price-to-work ratio will please the economical ones Customers: on average, a turnkey bath on a high foundation of concrete pillars will cost about 240 thousand rubles. The complex includes a room for rest, a shower and a steam room, each room has a size of 2x2.3 meters. The project is equipped with interior decoration, a stove with pipes and a shower tray, the walls are made of timber.

The manufacture of such structures is made on a turnkey basis, so the customer does not have to look for a team of builders, electricians, independently choose wood for construction, delve into the details of the foundation device. It is enough to contact the relevant organization, select a project, materials, agree on terms and pay for the work.

Pre-fabricated baths are installed on the site at any time of the year, regardless of the weather conditions and the depth of soil freezing. This allows you to set a bath in areas located in different climatic zones.

Pre-fabricated baths are compact and contain only necessary rooms with a minimalist finish. This approach to the design saves free space on the site and the financial resources of customers. In general, such a construction is a temporary option for connoisseurs of a steam room, or a budget solution for construction in conditions of economy or limited space.

Materials for creating ready-made baths

A common variant for building baths is a wooden beam. So, if turnkey ready-made baths are inexpensive, then there is a possibility that the bars did not dry out, which leads to the need to "shrink" before finishing work. Mobile buildings from natural timber provide a pleasant indoor microclimate, as well as durability and quick warming up of the steam room. Coniferous wood at the base of the profiled bar when heated becomes a source of volatile production useful for the respiratory tract.

Prefabricated vip sauna panels - a design based on two particle boards separated by insulation. This option has less weight, ready for finishing work immediately after installation. Similar designs look more modern than traditional baths from a bar, the exterior of the facade is performed with vinyl siding.

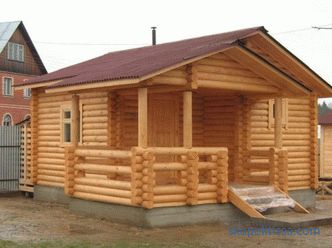

Owners of spacious country estates, as well as connoisseurs of unusual finishes will like ready log houses offered by companies to create baths.Such designs already require laying the foundation and large-scale interior decoration, but still save the time and effort of the customer, providing ready-made “walls” as an intermediate option between a turnkey bath and standard capital construction.

On our site you can find contacts of construction companies that offer a bath construction service. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Ready-made complexes of blocks (foam concrete, expanded clay concrete) have high thermal insulation properties, as well as a long service life. The disadvantage of the material is the need to install the foundation, which increases the period of construction of the entire bath complex. Exterior finish of such buildings is carried out with the help of facing bricks, clapboard, as well as siding or decorative plaster.

Equipment for the mobile bath

Depending on from the final price, materials of construction and the characteristics of the approach of each manufacturer, the equipment of the bath may vary.

A stove for a bath is a mandatory attribute of the finished building, complete with it is usually provided with a water tank. Some manufacturers offer installation of the oven to the taste of customers for a fee. This approach makes it possible to choose the model that is more suitable for the customer, but at the same time, the total cost increases, sometimes quite significantly.

The solution in this case is to buy a turnkey sauna ": it will be inexpensive, especially since the total amount of the project is approved until it is transferred to work. The presence and design of the furnace, shower tray, shelves in the steam room, as well as the finishing of the walls inside the room are coordinated before starting work, all elements are precisely designed for the parameters of the bath.

The foundation on the basis of which the structure is being built may be prepared by the customer or manufacturer. In the second case, solutions from concrete blocks are most often used, piles are also in demand.

These types of foundations do not require long-term soil preparation, they withstand a small construction weight, and are suitable for different climatic zones.

Walls, rough and fair floors are made of materials selected by the customer. In most cases, this is profiled timber and edged boards.

Mineral wool, linen-jute cloth is used as insulation , the steam room is finished with foil-based materials.

The windows have double glazing, and the door leaves are trimmed with clapboard, while the wood is carefully treated with an antiseptic.

The roof of the building is finished with a professional flooring (an analog of metal tile), undulin (soft tile), and roofing material (an economical option).

And for trips to the countryside, you can use the camping bath. Example in the video:

Features of the delivery of mobile baths

Affordable price, a variety of turnkey projects and natural materials lead to the popularity of prefabricated baths. Unfortunately, the construction market consists not only of bona fide businessmen who value their reputation, so there is a risk of delivering a poor-quality bath or losing money when it is ordered. Simple steps will help to avoid fraudsters.

The choice of the organization developer should do on the basis of reviews of friends, and carefully check the information about the company. Conscientious sellers are always ready to provide additional photos of their transport baths - finished projects, do not hide the legal and physical addresses of warehouses, manufacturing facilities and offices, so that customers can see the assortment live. The absence of a group in social networks and an official site is a reason to think about finding another artist.

The price of the finished bath may differ from competitors by 10-15% in both directions, too low prices - a reason to think about the integrity of the developer in terms of the quality of the materials used and the services provided in general.

The delivery of a disassembled mobile bath involves installation on the site using a manipulator, and it should be clarified whether the rental cost of the equipment is included in the bill. Finished buildings are brought to the site, fixed on the foundation or level ground, after which the craftsmen make the connection connections. In order to avoid fraud, it is necessary to thoroughly talk with the sales manager about the list of works included in the price.

Some manufacturers allow themselves to use raw wood for the production of pre-fabricated baths, to save time. Therefore, it is better to buy a ready-made bath from a log house without interior decoration and leave it to “sit down” during the year, so that the structure does not deform.

It might be interesting! In the article on the following link read about a 6x8 bath with a mansard.

Mobile bath inside and outside: original projects in photo and video

In the video, an example of a budget solution:

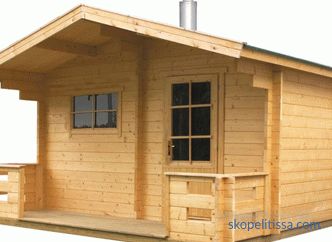

And several interesting projects ready turnkey baths in the photo

It may be interesting! In the article, read the following link about the chimney for a bath.

Conclusion

Affordable mobile baths are a quick option for those who want to complement the suburban area of a full-fledged steam room. A careful approach to the choice of the company-developer, suitable materials and prices will allow you to buy a turnkey transport bath inexpensively, taking into account all the desired design features.