Today we will talk about a single structure, which is often constructed in suburban areas, and it is also used in production areas. That is, it is a universal structure. So, we will talk about a lean-to overhang, about its positive and negative sides, about the materials from which such sheds are being built, and we also denote the step-by-step manufacture of a lean-to design.

Classification of a lean-to canopies

To begin with, and types of canopies in one ramp - a huge amount. Therefore, they are classified by feature, to simplify the selection.

The first separation is made according to the material from which this structure is made.

-

Metal profile . Determined by high durability, long-term operation, stability and reliability. The disadvantage is the complexity of installation. For fasteners use welding.

-

Wood . It is not inferior to metal, if the entire structure is subsequently treated with protective compounds: antiseptics, paint, varnish. The advantage over the first position is simplicity of assembly on screws or nails, plus special profiled elements made of galvanized steel.

-

Combined . Here, metal racks are most often used, and a roof for a shed is constructed of wood. There is another variant of symbiosis: the lower part is brick, blocks or stone, the upper part is lumber or metal profile.

The second division is by construction method.

-

Free-standing . They are built away from the main buildings. Usually used as a substitute arbors. Under such sheds put cars, organize a recreation area or a summer kitchen. This is a complete canopy with the maximum number of support columns.

-

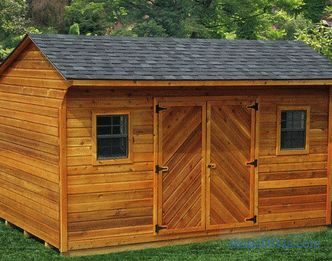

Attached . From the name it becomes clear that such sheds are attached to the main building or to some kind of utility block. In this purely constructive, it can be a full canopy installed on all racks, or it is a structure in which part of the racks is occupied by a wall or a roof of a house. In the photo below, this option is shown.

The third division is made according to the functional component. There are two positions:

-

Decorative , which are constructed to give the landscape design a finished look. Typically, these canopies are used as recreation areas. This group includes pergolas, that is, structures in which the roof is built without roofing.

-

Protective . Their purpose is to protect the canopy space from precipitation, sunlight and wind. Roof material must be mounted on the roofs of the shed. Some structures are covered with walls (partially or completely).

The fourth division can be made for its intended purpose. It can be shelters for recreation, for cars, for storing garden tools or household utensils. The fifth division according to the type of mounting structure. There are two positions: support, which are installed completely on the rack, and suspended, they are attached.

Now for the roofing. In this regard, there are no restrictions on the choice of material. Any one will do, the main thing is to strictly follow the rules for assembling the canopy itself, taking into account the size and weight of the roofing material, as well as the installation of the coating. Today, polycarbonate is very popular, for example, a transparent material with good technical data.

On our site you can familiarize yourself with the most suburban areas in the Moscow Region home . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

Construction Rules

We proceed directly to the construction of a shed with a lean-to roof. It is necessary to begin with determining the size of the structure. Or rather, from its height, width and length. There are no restrictions, no strict prohibitions. All at the discretion of the customer. Simply, if the span of the structure is large enough, then it is necessary to reinforce the structure by using materials of a larger section and installing additional intermediate posts. It is clear that this increases the cost of construction.

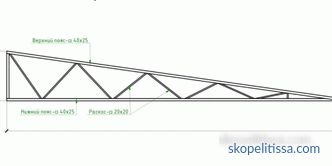

So, if we have decided on the dimensions, it is necessary to start manufacturing farms. The latter is the roof structure of the shed. Farms are straight triangles, where the hypotenuse is a truss leg. So that you understand what a farm is made of metal profiles, look at the photo below.

The number of trusses is determined by the size of the canopy and the weight of the roof covering used. For example, if the construction will be covered with asbestos slate, the installation step of the trusses is 1-2 m, if it is decided to use a professional flooring, then it can be increased to 3 m.

The next step is the installation of the supporting posts. First, the locations of the supports are put on the construction site, in which pits are dug with shovels or holes are drilled with an electric or hand drill. The depth of the supports is 0.5–1 m.

Gravel is crushed inside with a layer of 5–10 cm. The lower ends of the racks must be waterproofed. The easiest way is to coat them with bitumen mastic. Then the supports are installed in prepared pits, set vertically and at the same level in height. After that, concrete solution is poured into the wells. It must be tamped to remove air.

A certain period of time is allocated to the setting of concrete. Minimum - 7 days. Then go to the installation of farms, for which use the services of a crane. They are raised and installed on two adjacent supports. After that, the racks are welded by electric welding or bolted.

It can be interesting! In the article on the following link read about house with garage and carport: 3 accommodation options .

Next, the trusses are interconnected by several rows of crates. Elements of the latter can be made in the form of wooden bars or metal profiles. The installation step of the batten depends on the selected roofing material. For example, under a metal tile this parameter will be equal to 35 cm, under a slate of 80 cm, under a professional flooring depending on the type of coating: from 50 to 300 m. most often installed in suburban areas and used as recreation areas. Wood fits well into the landscape design of any style. Hence the great popularity of wooden structures. The simplest option is a small structure consisting of four racks.

The latter, as in the first case, are installed vertically in pre-drilled wells. Their lower ends must be waterproofed. To do this, use two layers of waterproofing materials: the lower bitumen mastic, external roofing material, which is pasted on the mastic.

For a small overhang, you can choose racks in the form of beams of 100x100 mm Since our design has a shed roof, respectively, two racks should be longer than the other two. The difference is determined by the angle of inclination of the roof structure. The greater the difference, the steeper the roof.

Therefore, the racks between them are set in pairs at the same height level. They are powdered with soil or concreted. After that, the straps are made in pairs. That is, a 50 mm thick horizontal board is installed and fixed between the posts of the same height. And already on the board lay truss legs. The photo below shows the construction of such a canopy.

It might be interesting! In the article on the following link read about 3 projects of a garage with a shed: what needs to be considered when planning a garage with a shed .

The structure of the combined shed

Here the construction scheme is the same. Simply, instead of metal profiles and sawn timber, support posts are erected from brick or stone. To do this, under them digging shovels square fossa. The size of the latter is determined by the cross section of brick pillars, depending on the required bearing capacity of the structure. The higher the last indicator required, the more powerful the racks should be laid.

In dug pits fall asleep crushed stone 10-15 cm thick, then sand, which is leveled and tamped. On the prepared pillow, ruberoid is covered in two layers. And they are starting to lay brick, blocks or stone on it. Raise the pillars or to one level, or in different pairs. Often, under the brick or masonry poured concrete bedside table (a kind of columnar foundation).

The video shows an option of raising support columns from a brick under a single canopy:

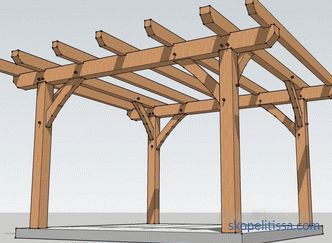

As soon as the racks are ready, they proceed to the construction of the roofing structure . Here, as mentioned above, lumber or metal profiles can be used. The photo below shows the wooden structure. It shows that the truss system lies on the posts, which rest against the brick racks. The roof can be made easier. To do this, two bars are placed in pairs in parallel, parallel to each other. And already on them in the transverse direction truss legs.

Construction of an attached structure

Here we must consider the option with one near support studs. That is, one side of the canopy will be attached to the wall of the building to which it is attached. There are several ways to secure the canopy to the wall.

-

To do this, use a board 50 mm thick . It is attached to the wall of the house with anchors, setting it horizontally to the height of the slope. It is on this board that the rafters will be installed, and they will be attached to it.

This can be interesting! In the article on the following link read about types of barbecue canopies and materials for their manufacture + examples in the photo .

-

For fixing grooves are made in the wall. This is only possible if the house is built of brick, blocks or stone. Rarely this method is used if the house is wooden. Usually under each truss foot choose a groove, where the rafter and insert.

-

Use special metal brackets . They are attached to the wall, and already to them rafter legs or trusses. The photo below shows one of the variants of this mounting method.

-

Truss or rafter mounted on walls built or on the roof . It is not always possible to use this option, especially if the house is already in use. Optimally - if a canopy with a flat roof is being built. Although there are no strict restrictions. For example, the photo shows an arched lean-to canopy, which is one side mounted on the wall of a building.

If it is not possible to attach the roof structure to the house, then build standard modification. That is, with racks on each side. In this case, one row of supports will be located near the wall of the building, to which the canopy is attached.

And one more thing. There is such a thing as a canopy with a flat roof. It should be noted that it is still a construction with a single-pitch roof. Just her angle of inclination of the slope does not exceed 5 °. So, the technology of construction of such sheds is exactly the same as described above. The same technological methods and building materials. The only thing that needs to be noted is that for protective type sheds, it will be necessary during the construction to pay special attention to the selection and installation of the roofing material. Optimally - to use corrugated board, laid without transverse joints, or use a roll roof, and preferably bitumen mastic for decorative qualities. Under the last two materials will have to lay a solid crate.

The video shows how a single-leaning canopy is being built from sawn timber:

It might be interesting! In the article next read the link about the highlight of the landscape - "floating" stairs and garden paths under which the grass can grow.

Conclusion on the topic

Simple and cheap building structures today at a great price. They are popular, do not require large cash outlay, but in terms of functionality and decoration they will not yield to other types. With the seeming simplicity of the construction process, assembling them is not an easy task. Especially if the construction is used semi-finished. Easier to buy ready canopy.