A blind area is an indispensable element for protecting the soil and the foundation from soaking with sedimentary waters. And it should be provided at the design stage. Therefore, the properties and dimensions such as width, thickness, angle of inclination are specified at the level of standards. The owner of a house under construction can only choose the type of coverage. And the most common option - the device of the pavement around the house of paving slabs or paving stones.

The choice of paving slabs is limited only by the imagination of designers of manufacturing companies

What you need to know about the layer-by-layer structure

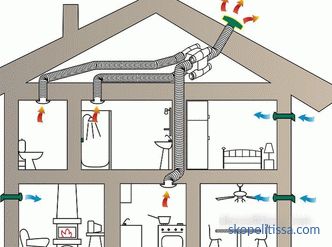

V the pavement of the tile is similar to a sidewalk or walkway, but with the obligatory presence of a waterproof layer. The rest of the structure is completely the same, even the profile should be with a slight bias so that the water flows down to the ground or into the gutters of the storm sewer.

The layer-by-layer composition of the pavement of the paving slab is as follows:

-

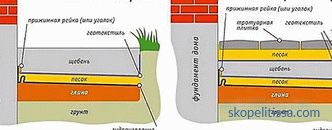

The compacted bottom of the trench ("trough") around the house. The depth should be such that all layers and the “underground” part of the paving slab fit. For backfilling and subsiding soils, the minimum compacted layer thickness is 15 cm. Already at this stage, the slope of the foundation is formed.

-

Pillow. According to the regulations, only filling sand is obligatory. But as the underlying layer under the sand can be used a mixture of crushed stone of medium and small fractions. The minimum thickness of the pillow is 10 cm, the recommended one is from 15 cm.

Arrangements for arranging the blind for

-

Waterproofing. The installation of a separation layer made of geomembrane or plastic film is recommended even under a concrete blind area (despite its water-tightness). For paving slabs, this layer is required.

-

Insulation. This part is not necessary, but the insulated pavement pavement around the house will increase the level of thermal protection of the building and reduce the effects of ground heaving forces.

-

Base under the tile. Depending on the method of tile laying, there are two types of base - sand-cement mix and monolithic concrete. The first option is easier to set up and repair the blind area, the second is stronger and more reliable.

The laying of the concrete base for the paving stone passes with the obligatory observance of the expansion joints at the base and along the entire length of the tape

-

Paving slabs or paving , curbs and storm sewer elements.

What should be the size of the blind area

The most important size in terms of protecting the soil from getting wet is the width. It is clear that when moistened, rocky or coarse-grained soils do not lose their bearing properties, therefore, the standards define the minimum width only for sandy and clayey soils.

In the first case, due to the ability to quickly discharge sedimentary waters, this size should be at least 70 cm, in the second case - 100 cm, with a slope of 1-10%.

The slope is necessary for removal of precipitation into the storm sewers

If the soils fall into subsidence, then the minimum width for Category I is 1 5 m, and for category II - 2. 0 m, with a slope angle of at least 3 ° (5. 2%).

Note. The subsidence includes many types of soil. They can be both porous and dense. And the physics of the process consists in compaction under its own weight and under external load conditions when the soil is wet, when water acts as a "lubricant", facilitating the movement of particles. It is possible to give an exact characteristic to the soil type by laboratory tests. Therefore, compulsory geological surveys before the design and construction of the house.

The height of the elevation of the blind area above the ground should be at least 5 cm.

On our website you can find contacts of construction companies that offer the service of designing houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Tile or paving

If they talk about paving slabs, they mean only concrete paving elements. And unlike paving stones, tiles for a blind area around a house can have the shape of not only “timber”, but also more complex geometry. Although the essence of this does not change, and performance properties depend on the material from which it is made.

For the differences between tiles and paving, look at the video:

There are three options: concrete, clinker and natural stone.

Concrete paving slabs

In turn, concrete paving slabs can be made in two ways: by casting and pressing. Although in both cases, vibration is used to compact the mixture.

The "classic" of concrete paving tiles is still relevant.

Vibrotated tiles are made using classical technology (except for dyes and special additives accelerating the ripening of the concrete stone).This is the usual "liquid" cement-sand mixture with high mobility and plasticity of the solution. Due to this, the mixture easily takes on any shape and is colored, and the surface of the tile is bright and smooth. In decorative terms, this is the most attractive material for paving, if not for low strength. It would seem that for a blind area such a property is not the main thing (it is rarely used for walking), but it is necessary to take into account the precipitations flowing from the roof. If an organized drain is not provided at the roof, then the blind area of paving slabs will quickly collapse.

Concrete paving stones can be the main element of landscape design

It can be interesting! In the article next link read about the blind area at home.

Vibropressed tiles are made using semi-dry concrete technology with simultaneous exposure to vibration in two planes. And the strength of a concrete stone, even without modifiers, is a quarter higher compared to the classical technology (with additives — one and a half times). And the main advantage is low water absorption and high frost resistance. But in the decorative relation it concedes to a tile received by molding - the muffled shades of color and simple geometrical forms. In addition, pressed paving slabs have a rough surface, although in icing conditions this is a “plus” for the walkway and the blind area.

Clinker paving

In essence, this is a solid brick clinker. Although there is a clinker tile, which differs from paving stone only in thickness. And if the basis for the blind area is a concrete monolithic slab, then use the tile laid on the cement mortar.

The brick tile laid on the concrete base will serve no less than paving stones on the adjacent site

Like concrete, it is also an artificial stone , but special grades of refractory clay are used as raw materials. Kinker paving stone is fired at high temperatures (up to 1580 ° C) and as a result, paving material is obtained that is not inferior to granite:

-

abrasion resistance class A3, T4 compression (maximum) ;

-

water absorption from 2 to 6%;

-

frost resistance can reach F300.

The recommended thickness for pedestrian areas should be between 40-45 mm, but the clinker paving for the blind pavement may be thinner. And this allows to reduce the cost of paving, as the cost of clinker is quite high - German paving stones have higher prices than domestic granite production.

The clinker can be safely laid on the mortar - service life up to 50 years

In addition to the high price, the clinker has a small color choice - from yellow to dark brown, and this is not a uniform color, but with transitions of shades of the fundamental tone. The color can be “adjusted” a little only by mixing several varieties of refractory clay, with a predominance of certain impurities of metal oxides: iron gives red hues, aluminum is orange, and there are additives that allow to get the blue-violet part of the palette.

Stone paving

This is one of the most ancient elements of paving. Basically, high hardness rocks are used - basalt and granite. And although the blind area is not a path (low permeability), but such “soft” rocks as limestone and sandstone can be affected by regular drops from the roof, if there is no organized drain.

Sandstone plitnyak looks great as a blind area around a country house

Usually a stone with sawn stone goes to the blind area of the paving stone ground surface, at least - with a stab. And the most popular breed is granite, which has a very high strength, beautiful texture and a fairly wide palette.

Granite paving with a stabbed surface is cheaper than polished, but in a decorative respect is not inferior to

Laying fineness

The blind area of paving slabs and paving stones is usually referred to as “semi-rigid” type. But this is only if it is placed on the preparation of a mixture of sand and cement. When a pavement blind area rests on a concrete base, this is already a “hard blind area”, therefore there must necessarily be a compensation gap (expansion joint up to 5 mm thick) between the base and the base, which is filled with bitumen-based sealer or laid with folded roofing sheet.

When laying tiles on a dry mixture of sand and cement (ratio from 4: 1 to 6: 1), so that the blind area does not "slip" from the base, first install the curb. And so that the flowing water does not erode the adjacent ground, it is necessary to install a storm sewer.

The work steps are shown in the following video:

The seams between the paving stones are made of the same materials used for base devices - a mixture of sand and cement or mortar.

It might be interesting! In the article on the following link read about the blind area around the house.

Conclusion

Any paving slabs or paving stones around the house in the landscape design of the house adjoining site look much more attractive and more organic than gray "dull" concrete. And in terms of strength and reliability, in most cases it exceeds it, since it excludes the possibility of improper preparation of the solution, as a result of which cracks subsequently appear on the surface of the blind area.