Polymeric materials have long been used in various fields of construction. The greenhouse made of plastic pipes will be an excellent solution that will save money. With the help of this material it will turn out to build a reliable and durable design with a long service life. All work can be done independently, without the involvement of specialists. The shape and size of the greenhouse can vary quite a lot, so it will turn out to choose the most suitable option.

Advantages and disadvantages of PVC greenhouses

PVC greenhouses are common and Much superior wooden or metal counterparts. This is due to the excellent performance indicators of such products, their low cost and long service life.

Also such greenhouses have the following advantages:

- Easy assembly procedure. Plastic differs in high plasticity thanks to what will turn out to create a framework of any size. It does not require special skills or devices.

- Low weight. If necessary, the greenhouse can be easily moved from one place to another without dismantling procedure. In this case, the frame can be disassembled and reassembled in a short time, so that during frost it will be possible to protect the structure.

- Excellent level of wear resistance. Plastic pipe does not require finishing with special protective solutions and mixtures. The material is not afraid of changing temperatures, moisture and fire.

- Low cost. The overall cost of arranging the plastic frame will be significantly less than when building wooden or metal varieties. Such a product will not need to be repaired, damaged areas can be easily restored or completely replaced.

- Greenhouses have a rather attractive appearance and will easily fit into any interior of the suburban area.

The main disadvantage of this choice can be considered low stability in strong winds. The design can sway heavily and even break away from the surface. But this minus can be easily leveled by installing supports at the corners or perimeter of the structure.

Greenhouse varieties

Such facilities may have a film or polycarbonate coating. A rather popular solution is the arched design. It has the following types:

- With a box on the basis of boards and arcs, strung on rods of steel.

- With plastic frame, arcs and tees of similar material.

They also often equip a greenhouse with a gable roof. It can have the following varieties:

- With film facing.

- With polycarbonate based coating.

Professional gardeners often recommend using double-layer PVC-based greenhouses. Such facilities have an excellent level of thermal insulation, as inside the greenhouse is reliably protected by polycarbonate sheets. Such designs give 3 times less heat than conventional counterparts.

On our site you can find contacts of construction companies that offer the installation of greenhouses and similar turnkey structures. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Preparation for installation of the greenhouse

Installation of the greenhouse from PVC pipes requires careful preparation. It will be necessary to perform the following procedures:

- Develop a greenhouse project

- Calculate the amount of material needed for construction work.

The quality of the erected structure depends on the correctness of the performance of these works.

Greenhouse project and material calculation

If the work is done by an experienced builder, if desired, he will be able to independently develop a project and carry out drawings for it. In other cases, it is recommended to use ready-made designs. Drawings of such constructions can be found on the Internet or in various magazines related to gardening. Often the schemes are quite detailed, so no complications should arise.

Often, an arched structure with a length of 6 m, a width of 3 m, and a height of 2 m is chosen. Such dimensions provide optimal space for plants, and the height of the building allows a person to be in it. The length can be extended if desired.

The following materials will be needed to assemble the product:

- Polypropylene pipe diameter of about 30 mm and a length of 70 m.

- Boards for creating the box. You will need boards with dimensions of 2.5 by 20 by 600 cm.

- Boards for the construction of a ridge and longitudinal panel. You will need products with dimensions of 2 by 9 by 600 cm.

- Planks to create a door and strengthen the gable.It will be necessary to purchase panels 2 by 7 by 300 cm.

- Fitting-cross. It is selected based on the size of the pipe.

- Fitting tee. It is selected similarly to the crosspiece.

- Self-tapping screws of any kind.

- Polyethylene for the reinforcement of structures.

- Hinges for mounting a door or vent.

Quite often, the project provides that a greenhouse will be removed from the greenhouse in winter. If it was decided to abandon this, then the interval between the arches can be slightly increased. This will prevent damage to structures under pressure from the snow. Also for such structures will need to use a longer pipe.

It might be interesting! In the article on the following link read about greenhouses made of glass.

Recommendations for choosing the material

Plastic pipes are of several types. For arranging greenhouses polypropylene, PVC or metal-plastic varieties are best suited. All of them are characterized by good strength, protection from the effects of temperature, moisture and mechanical pressure.

Polypropylene material is poorly bent and has thick surfaces, but if you wish, you can bend the arch. PVC and metal-plastic types are made on the basis of a softer plastic, the coating thickness of which is 1.5 mm, so that you can bend them without any problems. If you use softer products, experts advise to reduce the interval between the arches.

When choosing boards, it is better to prefer materials from larch. Pine and spruce rocks do not have optimal protection against moisture, and after a while it may be necessary to replace the panels. Boards for the base should be selected in the same way. Also do not forget about the antiseptic lining.

Beforehand, you will need to prepare all the necessary tools:

- Hammer and mallet.

- A hacksaw for processing metal and wood.

- Screwdriver.

- Level and measuring tape for measuring.

- Sharp knife.

Greenhouse construction procedure

After all the materials have been prepared, you can proceed to the main work. It is best to carry out a similar procedure together, additional help will not interfere with bending and installation of pipes. The process consists of the following steps:

- Preparing the area for arranging the structure.

- Assembling the box.

- Assembly of the frame.

- Facing the frame with foil.

Preparation of the area

The installation of the greenhouse is carried out on site, which will be well lit by the sun throughout the day. The surface must be flat, without holes. For marking, you will need to use a shovel, stakes and thread based on nylon.

The preparation procedure is as follows:

- On a plot with Roulette is marked by a rectangle. On each side you will need to make an interval of about 30-50 cm, while taking into account the dimensions of the future structure. In the corners of the rectangle mounting pegs are carried out, and between them the thread is stretched.

- Along the perimeter of the site, the top layer of soil is removed and a hole is pulled out with a depth of about 25 cm. Roofing material is laid at its bottom with an overlap of 10 cm and rubble is poured from all sides. The thickness of the backfill layer should be about 10 cm.

- If the area has an irregularity greater than 5 cm, then before digging the hole, you will need to level the surface. You can pour the soil, or vice versa remove it. The first method is optimal.

If the height difference is too large, for example, the structure is mounted on a slope, then a wall on the basis of a brick or bar treated with protective solutions should be laid under the subsidence area. Then dumping is performed until the terrain is completely level.

Collecting a box

A greenhouse from pipes has a box in its construction. For its assembly and installation, you will need to perform the following procedures:

- The wood panel for the box is installed based on the size of the greenhouse. For this, 2 products with a length of 3 and 6 m are used. The panels are connected using self-tapping screws. The short panel should be directed to the end of the long board, then 2 screws are screwed in with an interval of about 20 mm from the edge. To increase the strength of the structure, a corner based on steel is installed in the corners.

- The assembled structure is treated with antiseptic wood compounds and installed in a pit. The visible area should not be raised above the ground surface by more than 10 cm. To raise the box to the required height, you can pour a small amount of sand.

- Inside the pit you will need to install special holders for the arches. They should be installed around the perimeter of the box, no more than 10 cm of the product should stick out from the ground.

- The final stage will be filling the pit and checking the correctness of the placement of holders using a level.

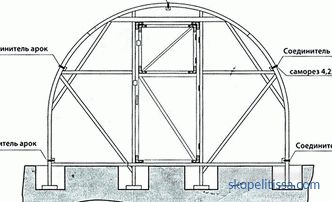

Collecting the frame

The assembly procedure for such a structure consists of the following work:

- At the end of each pipe, an acquired PVC tee is installed. For arranging the longitudinal sections in the lower part of the frame, it will be necessary to measure the spacing between the crosspieces and cut the necessary blank from the pipe.

- The cut products are mounted in crosses. If necessary, it can be rotated, and to ensure good shrinkage, it can be slightly hammered with a hammer.

- Before mounting the arc, experts advise to bend the pipe to give the necessary bend. After that, the installation of the pipe into the tee and its folding to the formation of an arc of the required height is made.

- When the arches are installed, it will be necessary to reinforce the structure using boards. To do this, the panel is installed from the inside of the frame. Fastening is done with screws.

- The ridge board is installed from the outside of the frame. To do this, it is placed on top and attached with screws to the arches. The length of the mount must not be more than 40 mm.

- Wood panels are also used to increase the strength of the gables and the ends of the structure. Blanks of the required size are cut with a hacksaw.

- Installation of end bases is in progress. To ensure good stability, a longitudinal board is installed between them. After that, similar procedures are performed to create supports at the edges.

- Billets are cut from the boards for mounting the door. With the help of screws and a corner of steel going frame for the door. Plywood is suitable for facing the bottom of the structure.

To install the door, you need to divide the loop into parts. One of them is attached at the top and bottom of the central base, and the other - on the design box. Then the door is finished with a film and mounted in the prepared opening.

Facing the frame with film

For this procedure, you will need to carefully follow the work technology. The procedure is as follows:

- Reinforced fabric with a thickness of 200 μm is spread over the frame so that the same distance remains from the ends and from the bottom.

- For fixing the film, blanks on the basis of pipes about 60 cm long are used, which are mounted in the lower part of the structure. They are attached to the longitudinal tube and attached with screws.

- Deaf greenhouse walls are treated in the same way. The fabric is gently tensioned between the supports and attached with the help of battens made of wood and nails.

In order to avoid fabric fluttering under strong wind, you will need to fasten it in several parts of the frame. To do this, you can use special sliding brackets or small pieces of plastic pipes.

It may be interesting! In the article on the following link read about the winter greenhouse.

Total

Installation of a greenhouse on the basis of PVC pipes will be an excellent solution for a country site. The cost of construction is minimal, but it will be of great benefit. The works are not labor intensive, so even a beginner in the construction craft can cope with them. The main thing is to carefully follow all instructions and recommendations.

Rate this article, we tried for you