A type of base for light and ultra-light structures is a columnar foundation. This construction of the foundation is one of the cheapest, so it is often used in the construction of small household and suburban buildings.

Application, advantages and disadvantages of a column base

In some situations, the foundation on poles it is preferable to other structures:

-

Construction of the building with walls of light building materials and without a basement.

-

During the construction of temporary barns and other outbuildings.

-

The need to save as much as possible on the foundation.

-

All of the above, plus the inexpediency of building strip foundations.

In addition, the popularity of the column base is characterized by the following design advantages:

-

it takes minimum time to mount the columns;

-

low labor costs

-

availability of building materials;

-

usually there is no need for special construction equipment;

-

requires a minimum of materials for heat and moisture insulation;

-

a long period of operation;

-

the possibility of mounting the structure on soils prone significant freezing;

-

simplicity in maintenance and repair of the structure;

-

the cost of the columnar base is significantly lower compared to other foundations.

Installation of a column structure is not recommended in the following situations:

-

the presence of weak or mobile soil on the construction site;

-

the soil is composed of a significant portion of peat or clay;

-

high level of groundwater occurrence;

-

the use of heavy building materials and the construction of several floors;

-

differential heights on the construction site more than two meters.

Also, the column basement will have to be abandoned if for some reason a basement is needed under construction.

Structure and type of device

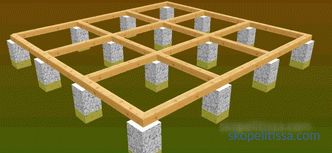

The column base is poles installed in a specific order, holding the structure and transferring loads from it to the soil.

Usually at the column foundation the distance between the columns is from 1. 5 to 2. 5 meters from each other. Less simply impractical - then the trump card of the foundation - cheap, will be questionable. No longer done because of the possible sagging of the lag and the loosening of the whole structure in the future.

Mandatory columns are mounted at angles, points of intersection of walls, along the line of installation of load-bearing walls and beams of the future structure.

In the section, the support section can be round or rectangular. Different materials can be used for the production:

-

Monolithic reinforced concrete . The most durable and stable design, which is made of concrete, reinforced reinforcing bars.

-

Brick . It is recommended to use a red solid ceramic brick. It has high strength, is resistant to low temperatures and does not absorb moisture.

-

Concrete blocks . Slightly inferior to monolithic reinforced concrete. But for their installation it is necessary to use special equipment, since the blocks have a significant own weight.

-

Booth or Botobet . Mixture of rubble stone with concrete. Suitable for light outbuildings, but significantly "weighted" the estimate. It will require careful selection of stones, since the support density depends on the degree of their adherence to each other.

-

Tree . Recently, wooden pillars for the foundation are used only for temporary and lightest buildings. In any case, solid wood is used: oak, pine or larch.

Combining the pillars into a monolithic structure is carried out using a grillage.

Types of grillage

So that the load from the structure is evenly transferred to the ground, on the columns set the grillage. It combines columnar structural elements into a single system and minimizes the difference in shrinkage of the base pillars. At the stage of installation of columnar bases, a special pin or bolt is installed in them, on which a grillage will later be mounted.

Options of the grillage equipment:

-

Wooden beams with a large cross-section. Used for wooden buildings of low weight.

-

I-beams or T-frames. Can be used as a separate element, or serve as a base for wooden logs.

-

Concrete beams - can be prefabricated or monolithic. They are installed, if necessary, to ensure maximum stability and durability of the building, if dense wood or relatively heavy construction materials are used for the construction.

On our site you can find contacts of construction companies that offer the service of building small architectural forms (gazebos, hozbloki, grill houses) turnkey. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Calculations for the installation of column supports

Before installing the structure, it is necessary to perform the necessary calculations and prepare the construction site.

Before starting the calculations, it is necessary to take a soil sample at a depth of 0. 5 meters below the pillar mounting level. The analysis will allow to understand whether the soil is suitable for the installation of a columnar foundation.

Required calculations include:

-

Determining the weight of a future building. This allows us to determine the total pressure on the ground: the total mass of walls, floors, roof, wind load, planned furniture.

-

Calculation of the number of supports . The perimeter of the structure is divided by two meters (step of mounting supports). In addition, it is necessary to add pillars that will be installed under the internal supporting walls and crosshairs.

-

The area of support columns . Tabular value. For example, the support area with a diameter of 40 cm is 1250 cm. Square.

Their number directly depends on the area of the supporting pillars. The smaller the footing area, the more their number must be installed.

For each material the minimum size of the support section is established. For monolithic reinforced concrete, this value is 0. 3 meters, bricks - 0. 38 meters, concrete - 0. 4 meters, rubble and butobeton - 0. 6 meters.

The calculation of the base of the pillars must be carried out in such a way that the support size exceeds the wall thickness by 10 centimeters - 5 centimeters on each side.

It can be interesting! In the article on the following link read about base plates.

Preparation for work

The beginning of the robot begins in the preparation of the construction site and materials. To ensure the construction it is necessary:

-

Clear the site from debris.

-

Plant soil should be removed to a depth of 15-20 cm and two to three meters to the sides of the construction site.

-

Carry out the alignment of the construction site, check the flatness of the site. For this, use the construction level, installed on the board, a length of about two meters.

-

If clay soil is found under a cut of fertile soil, then a sandy-gravel pillow should be equipped.

After the site is ready, you can proceed to construction.

Construction work

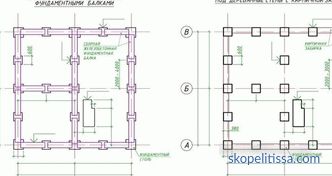

A breakdown of the base

The essence of the work lies in the fact that the installation of the supports is transferred from the drawing to the building site.

Before the breakdown of the base, along the perimeter of the future construction, at a distance of one or two meters from it, a so-called obnite is made. These are ordinary posts, on which wooden planks are filled. Between the slats, the rope is stretched, which will mark the construction site.

Theodolide checks the underside of the site, the angles of the future structure and the junctions of the walls. The mark after verification should be similar to the design indicator.

Good to know ! Theodolite is a measuring instrument for determining horizontal and vertical angles in topographic surveys, geodetic measurements, in construction and other works.

It might be interesting! In the article on the following link, read about how and with what to warm the foundation of the house outside.

Pits for supports

Under reinforced concrete or prefabricated bases, pits are dug using special equipment or manually. The pits should be vertical.

If the soil is not loose and the depth of the pit does not exceed one meter, then its walls can be straight. When the depth of the pit is more than one meter or in the presence of loose soil, the walls of the pit are made inclined outwards.If necessary, strengthen the boards or struts.

The depth of the pit under the pole should exceed the design value by 0. 2-0. 3 meters.

The width of the pit should differ from the design width by 0. 2-0. 4 meters to each side. This will give the opportunity to freely mount the formwork and install struts.

Under the round pillars of the pit, a special automatic or manual drill is performed. For broadening the base, a drill equipped with special folding knives (TISE) is used. At a given depth, the knives open and perform the design broadening of the base.

In any case, the width of the column base should exceed the width of the walls of the future structure.

On our website you can find contacts of construction companies that offer the service of auditing construction work. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Construction of a cushion

A sand-crushed stone or just a crushed-stone pillow is installed under each pillar - this will eliminate frost swelling. The pillow should exceed the size of the base of the column by 0. 1-0. 2 meters on all sides.

The bottom of the pit to a height of 0. 1-0. 15 meters covered with rubble, which after filling is rammed. A layer of coarse sand, about 0. 1 meter high, is laid on tamped rubble, poured over with water and rammed. The overall height of the layer should be such that after its laying it was possible to reach the zero level of the installation of the base of the column. So that the concrete that will be poured does not leave the water, the pad is covered with polyethylene or roofing felt.

When installing pits under round poles, the principle of installing a cushion is the same. Tamper is performed with a long pole.

It may be interesting! In the article on the following link read about the foundation for the house.

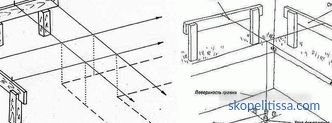

Installation of formwork

Reusable, or disposable, non-removable formwork can be used to make concrete monolithic columnar supports.

Reusable formwork is a structure that is made of various materials and can be assembled in different versions. These can be:

-

Boards, which are knocked together in shields of various dimensions.

-

Plywood sheets, 1-1.5 cm thick.

-

Removable metal formwork.

-

Plastic prefabricated formwork.

Metal and plastic formwork are often used in industrial construction.

For wooden formwork, a planed single-sided board is used, with a thickness of from two to four centimeters and a width of 12-15 cm, with a moisture content of not more than 20%. The installation of the boards is carried out with the stripped side inwards. Boards or plywood for formwork must be wet. Otherwise they will absorb moisture from the concrete.

Pipes made of solid cardboard or plastic, with a thickness of 0.5 to 2.5 cm are used as a one-off formwork. The diameter of pipes and their length can be of various sizes. The inner surface of the pipe is treated with a water-repellent solution. The role of disposable formwork can perform the usual ruberoid.

Brickwork, asbestos or plastic pipe, the same roofing material can be used as fixed formwork. After filling with concrete mortar, such formwork is not removed.

Rebar glass

Formed from reinforcing bars with a diameter of 1. 0-1. 2 cm. The number of rods in one column can reach from 4 to 6 pieces. Can be placed in a square or in a circle. Throughout the entire length, every 15–20 cm, the reinforcing bars are twisted with a wire frame or ring, for which reinforcing wire with a diameter of 0. 6–0 is used. 8 cm. Such a connection will give stability to reinforcing bars, rigidity of the reinforcing structure and the columnar base as a whole. The distance from the reinforcing bars to the formwork should not be less than five centimeters.

If you plan to subsequently build a monolithic concrete grillage, then it is recommended to bring the reinforcing bars out - this will simplify the coupling of the posts to the grillage. If you plan to install a wooden, I-beam or T-beam, it is advisable to provide for the installation of a mounting rod or bolt in solidifying concrete.

will be installed on the pillars. It might be interesting! In the article following the link read about the pile-grill foundation.

Pouring mortar

For a conventional reinforced concrete base, the solution is poured in parts of 0. 3 meters high. Each such part is separately vibrated so that the air bubbles come out. This procedure is repeated until the internal capacity of the formwork is filled to the design height.

If masonry is used under the pillars, the mortar is made from Portland cement, not less than M300. The best option is the M500 brand. The solution can be several production options:

-

Cement - 1 part, sand - 3 parts.

-

Cement - 1 part, sand - 10 parts, limestone - 3 parts.

-

Cement - 1 part, sand - 10 parts, clay - 1 part.

For rubble masonry, stones more than 25 cm thick are used. Laying is carried out on the mortar with the maximum fit of the stones to each other. Voids are filled with medium or fine gravel, followed by tamping. To increase the strength, the reinforcing lattice can be installed in any position with rubble masonry.

The supports of the column foundation must be of the same height. To do this, you must constantly monitor the vertical plane and "beat off" the extra value. The frozen top is difficult to remove and requires extra costs.

How is the installation of the reinforcement cage and the pouring of concrete done, see the video:

Decorating the underfloor space

When erecting a building on a columnar the foundation, between the ground level and the grillage (rough floor), is a ventilated space. This has a positive effect on maintaining a constant level of moisture in materials, but it negatively affects the insulation of a room. In addition, animals can settle in the empty space. Therefore, in most cases, trying to sew empty space. To do this, use one of the options:

-

Upholstery around the perimeter of sheet or finishing material. Carrier rails are attached to the foundation pillars. To them, with the help of screws or galvanized nails, finishing material is attached.

-

Making a wad. Between the columns of brick or stone is laying in one row. At the same time, you can mount decorative elements for cylindrical pillars of the foundation.

Both options may have their own designer beauty, but the option of zabirki will cost a little more.

Attached structures

Often, to an already built building can be added additional construction. In the case of a columnar foundation, when the “box” does not stand on the ground, at a minimum, a porch can become such a construction. Also, another room can be added, which by its mass will be lighter than the existing one.

In any case, our own contour and its foundation are made for the attached structures. This is done because the structures have different mass and if they are rigidly connected, then in case of shrinkage of the main “box”, the extensions will be deformed and collapse.

The consequences of this error are shown in the following video:

The "box" foundations and extensions should not be in contact. Between them is established deformation seam. For the seam using dense materials with good absorption. For example, folded ruberoid folded in several rows, mineral wool, rubber pads.

On our website you can find contacts of construction companies that offer the service of installation and repair of foundations. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Conclusion

The biggest plus of the columnar foundation is in its price, because for this reason specific building materials or highly skilled workers are not needed. But you should always remember that the columnar foundations are intended exclusively for light buildings. Building on this basis a residential house will not undertake any specialist who concludes an agreement with you, where the warranty obligations will be prescribed.