The material for the waterproofing of the roofing pie is selected depending on the type of finishing coating. The article tells about waterproofing for the roof under the metal. The proposed material contains information about the features of a metal-tiled roof, the functions of waterproofing and the requirements placed on it. You will get acquainted with the varieties of waterproofing materials and features of their installation.

Features of the roof made of metal

Metal is among the most popular roofing materials and is a profiled steel (less aluminum or copper) sheets, the appearance resembling ceramic tiles. A characteristic feature of the product is the top protective and decorative layer of polymeric material (sometimes it is a paint-and-lacquer layer), which improves the performance of the sheets and makes the choice more diverse.

An important property of metal-tiled sheets, which should be remembered when choosing materials, is their high thermal conductivity. The ability of the metal to quickly transfer heat and cool leads to cooling of the nearby air mass and the formation of condensate. This is an extremely undesirable phenomenon; it leads to an increase in humidity and the appearance of dampness (and, in the long run, mold). Condensate penetrates the insulant and causes a reduction in the heat-shielding parameters of the roof structure and the life of the roof.

The durability of the roof covered with metal tiles is largely determined by the correct composition of the roofing pie, in which waterproofing plays an important role layer.

What problems the hydrobarrier solves

Waterproofing the roof of metal tiles is designed to perform the following functions:

-

Protect the roofing space, including the truss system, from atmospheric water .

-

Protect the insulating layer from water vapor and condensate , and, therefore, maintain energy-efficient housing.

-

Maintain the optimum temperature and humidity regime in the under-roof space.

-

Serve as protection against dust and dirt penetrating with a current of air.

If you forget about waterproofing

The reason why waterproofing the layer was not installed (mistake, forgetfulness, or the desire to save), leads to very unpleasant consequences:

-

Damage to the rafter system. Condensate trapped on the rafter framework, sooner or later leads to a change in geometry. Wooden structural elements absorb moisture, mold settles on them, rotten areas appear, which quickly collapse and reduce the strength of the roof.

-

Damage to insulation i. The heat-insulating layer which is not protected from moisture easily absorbs atmospheric moisture and dampens. Crude insulation though will not rot, but will worsen the insulation of the building; heat will go through the roof, heating costs will increase. It is almost impossible to dry wet insulation, it must be replaced; otherwise, high humidity and positive temperature will lead to the need for major repairs.

-

Corrosion of metal tile . This practical material has vulnerable areas - attachment points to rafters with a broken polymer layer. If there is no hydroprotection layer, moisture is delayed and starts the corrosion process. This leads to further detachment of the polymer layer, the emergence of through holes and reduce the reliability of the structure.

Requirements for hydraulic protection

Of whatever material the waterproofing for the roof is made of metal tiles, it should serve as a reliable protection for the thermal insulation layer and the attic space. Any waterproofing films purchased for metal roofing should ideally be micro-perforated to circulate water vapor. When choosing a material it is necessary to pay attention to the following film characteristics:

-

Vapor permeability index . It depends on the material, the number of layers and their thickness. Property important for warm roofs.

-

Resistance to rupture . Some films are composed of reinforced layer, which increases the strength and reliability of waterproofing.

-

Operation temperature . The best performance is from -70 to + 100 ° C.

-

Fire resistance and UV resistance.

-

Stability against atmospheric effects.

-

Weight , environmental friendliness , service life (ideally should coincide with the life of the finish coating).

-

Value for money .

On our site you can find the contacts of construction companies that offer the roof repair service. You can directly communicate with representatives by visiting the low-rise country exhibition.

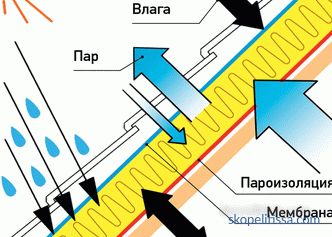

Choice of protection

Condensate formation is affected by whether the roof is warm or cold. The air temperature from different sides of the roofing cake will determine the place of condensation of water vapor, their volume and intensity. Consequently, the structure of the roof determines the choice of waterproofing the roof of the metal; The materials offered in the construction market are divided into three groups according to the nature of hydroprotection.

Classic (polyethylene) film

Budget option that exists in three varieties:

-

Single-layer film . It is characterized by the lowest price, but also the corresponding durability. Its use in the roofing cake is better not to consider.

-

Reinforced . Three-layer version, more durable thanks to the middle reinforcing fiberglass layer.

-

Perforated . The material has not received widespread acceptance, although it has vapor permeability. The reason is the low strength of the film and its tendency to clog the holes, which leads to a decrease in important properties.

The advantages of this material include an attractive price, a wide temperature range of operation and, in most cases, almost complete waterproofing. The lifetime is influenced by the quality of the material, which often falls short of the standards; therefore, it is useful to purchase film from reputable manufacturers that guarantee quality.

The minus of the material for use in the metal-tiled roof cake is a high probability of damage by metal hardware and zero vapor permeability, which allows using the film only as a vapor barrier (under the insulating layer).

Most often, such material is used as a temporary solution (for the period of repair), for hydro-protection of outbuildings or as a steam insulator for a warmed roof. When used as a waterproofing, arrangement of ventilating layers will be required, both under the final coating and on the side of the insulation.

About testing roofing films in the following video:

On our website you can find contacts of construction companies that offer the service of reconstruction and rebuilding of houses. You can directly communicate with representatives by visiting the low-rise country exhibition.

Anti-condensate (polypropylene)

The polypropylene film also includes a reinforcing layer. In addition, the upper and lower sides have different properties:

-

Smooth outer (facing the metal tile) surface does not let the moisture in.

-

The rough bottom (inner) side is covered with a pulp and viscose pile. The coating retains moisture and prevents it from entering the insulation layer and structural elements; gives her time to evaporate and leave the roof space. In order for the anti-condensate film to function properly, dual-circuit ventilation is necessary.

The advantages of the material include its long service life (from 20 years) and effective protection against moisture at any temperature. Specialists also note its high strength and immunity to minor damage. The disadvantages are the price (more expensive than the classics) and the inability to skip steam, which limits the possibilities of application (not suitable for insulated roofs).

A line of steam and waterproofing materials of the Izospan brand has gained wide acceptance in the construction market. Films allow you to provide comprehensive protection for your home, extend the life of its structures and maintain a comfortable microclimate in residential premises. The question of what "Izospan" to use for the roof under the metal tile, is solved depending on the type of construction being erected.

On our website you can find contacts of construction companies that offer the service of completing unfinished houses. You can directly communicate with representatives by visiting the low-rise country exhibition.

Diffusion membrane

Most of the diffusion membranes are made of polypropylene, but thanks to a special technology, they have distinctive properties and are more popular. The waterproofing membrane, as well as the anti-condensate film, also has sides with different properties that cannot be confused during installation. It works on the same principle; however, the membrane has a high vapor permeability and allows water vapor to pass in one direction.When using a membrane, ventilation is needed only between the hydrobarrier and the finish coating.

Depending on the ability to pass steam, the membranes are divided into three types: small, medium diffusion, and superdiffuse. The latter are able to remove more than 1 liter of water during the day (from one square of the surface). Membrane films have the following advantages:

-

Long service life . The films are designed to function for a period of at least 25-30 years. The service time of some models (reinforced) reaches 70-80 years.

-

Temperature stability . Freeze / thaw cycles do not reduce the waterproofing ability of the material.

-

Excellent vapor permeability . In a short time removes steam and condensate, reducing humidity to a safe level.

-

Operational parameters . The membrane is durable, easy to install, resistant to mechanical loads and hassle-free use that does not require special care.

About the installation of the roofing pie in the following video:

The disadvantages of membrane films are their cost and some restrictions on use ( for some models) - in order for the film to function properly, the angle of inclination of the roof must be at least 35 °.

It may be interesting! In the article on the following link read about the review of insulation for pitched roofs.

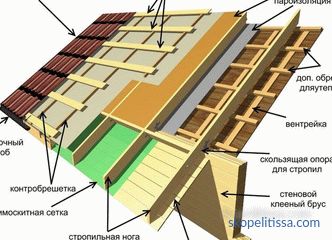

The underlay for a warm and cold roof

The standard roofing pie for the roof, under which the living quarters are arranged, looks like this:

-

Metal tile above the counter-lattice and crate.

-

A quality waterproofing layer protecting the insulation.

-

Air (ventilation) clearance on the crate , which provides air circulation along the barrier.

-

Thermal layer . Mounted in the roof system, the thickness is selected depending on the climatic conditions of the region.

-

Vapor barrier . Protects insulation from saturated air from residential areas.

-

A lining of the attic ceiling separating the roofing pie from the dwelling.

The cold (unheated) roof edge is mounted according to a simpler scheme and includes The following layers:

-

Metal above the counter-lattice and the batten.

-

Waterproofing layer . An anti-condensate and diffusion film, as well as any material with suitable moisture protection parameters, such as greenhouse film or roofing felt, will be suitable for the role of a hydro-barrier.

-

The rafter system .

It can be interesting! In the article on the following link read about drains and drain systems Aquasystem.

Features of installation of waterproofing under a metal tile

When installing a metal-tile roof, experts recommend laying various types of a hydro-barrier according to the following rules:

-

Anti-condensate films placed between the finishing coating and the insulating layer, adsorbing (rough) side to the insulation. Installation should be carried out in warm, dry weather.

About the installation of waterproofing in the following video:

-

As an anti-condensate film and the diffusion membrane is placed on a counter-lattice, whose purpose is to form a gap between the waterproofing and insulation. From above, the film is covered with a second counter-grill on which the metal tile is mounted.

-

A variety of diffusion films is offered on the market - a double-sided membrane, which can be laid on top of the insulation layer on either side.

-

A variety of membranes - superdiffusive membranes based on nonwoven canvas with two or three layers, which are used to remove steam from the insulation. The main difference is that this material does not need ventilation, the film is placed on the inside directly on the insulation.

-

A feature of membrane materials is their low stability with respect to ultraviolet , therefore, they are trying to be installed in a short time.

-

All roll films are not mounted in the tightness ; This protects them from deformation and damage when the temperature changes.

It might be interesting! In the article On the following link, read about a house decorated with white cedar in Quebec.

Conclusion

The most popular material for waterproofing a roof in a country house building is a waterproofing film. The absolute rule for installing a warm metal-tiled roof is to create a vent layer next to a hydro-barrier with the help of lathing.Ignoring the rule leads to an increase in humidity and loss of functionality of the roofing pie, and in the future - to a violation of the integrity of the roof structure. The cold roof device allows the use of roofing material as a waterproofing.