In this article we will tell how to choose the right heater for the roof. What parameters you need to pay attention to, the steps of competent assembly of the heat-insulating cake on the roofing structure. After reading the article, you will be able to “on the same wavelength” communicate with the master about the choice of the necessary material, and if necessary, check the workers performing the thermal insulation of the roofing system.

Requirements for a heater

Let us immediately designate that there are a lot of criteria for insulation materials . And each of them does not meet all the criteria. Different heaters have pros and cons. And the consumer always faces a choice, preferring one or another characteristic.

So, if we talk about the ideal insulation on the roof, then it must meet the following criteria:

-

Low thermal conductivity. Here the question is put this way - the lower the better. But there is an upper limit - no more than 0.05 W / m K.

-

Density. Excessive load on the roof structure is not needed. Therefore, the less heat insulation material weighs, the better.

-

Low hygroscopicity. This property of the material to absorb moisture. With increasing humidity, the thermal performance of the insulation decreases. And although today the problem is being solved using protective films, it is better to give preference to those products that have this characteristic low.

-

Fire safety indicator. Unfortunately, we must say that a large number of insulating materials can not correspond to the maximum value of this parameter. But among them there are those who do not burn and do not sustain combustion.

-

Stable condition. That is, during operation, the insulation should not change its shape and size.

-

It should not be the place where harmful microorganisms, rodents, insects or birds would appear.

-

Insulation should not be dangerous to humans.

-

Reasonable price.

On our website you can find contacts of construction companies that offer the service of calculating and carrying out work on the weatherization of a turnkey private house. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Best insulation

Criteria are marked, let's try them on with different roof heaters and decide which one is the best. This article will not disassemble the materials of the bulk type, which are used for warming flat roofs. Consider the plate and sprayed types.

Plate insulation is a material with a fibrous or gas-filled porous structure. Sprayed ones also belong to porous materials, just their application method is foam, which turns into a durable heat insulating mass in the air.

It should be noted that fiber insulation, where mineral wool is a prominent representative, are hygroscopic products. Therefore, they are closed on both sides with protective membranes. Today, many manufacturers offer miniwat, in which this parameter is greatly reduced. But experts recommend that protective films should not be abandoned when the mineral wool is chosen as insulation for the roof.

Characteristics of thermal insulation materials

To choose the best thermal insulation material for the roof, compare between the characteristics. Let's reduce them in one table. But first we will designate that we will compare three materials: mineral wool, polystyrene foam plates, polyurethane foam. They are most often used for thermal insulation of pitched roofs. That is, the dispute - insulation for the roof: which is better - will be resolved between them.

| Specifications | Thermal insulation materials | ||

| Mineral wool | Polystyrene foam plates | Polyurethane | |

| Thermal conductivity, W / m K | 0.03- 0.05 | 0.028-0.044 | 0.019-0.028 |

| Density, kg / m³ | 75-200 | 10-35 | 40- 70 |

| Water vapor permeability, mg / m h Pa | 0.64 | 0.05 | 0.02-0.05 |

| Flammability group | NG (non-combustible) | G3, G4 | G3, G4 |

| Water absorption, kg / m² in 24 hours | 1 | 0.2 | 1 |

| Form | mats | plates | foam |

| Price, rub./ m² | 500-1000 | 200-250 | 1000-2000 |

It might be interesting! In the article on the following link, read about how to warm the pile foundation of a wooden house.

Comparative analysis shows that polyurethane foam in terms of thermal conductivity is the best option. But it is a combustible material. The same can be said about polystyrene foam plates. But the latter two options are hydrophobic materials, so their installation does not require additional protection. Mineral wool wins mainly on the degree of flammability. Although the thermal conductivity of the rest has not gone far.

As for the price, here you need to take different positions into account. For example, density, thickness of the stacked layer. At the same time, mineral wool is sold per 1 m², polystyrene plates and polyurethane foam per 1 m³. But in any case, the latter is not a cheap pleasure.

So, having dealt with the question of roof insulation - which one is better, we proceed to the topic of its proper installation.

Rules for installing insulation on a roofing structure

To begin with, the roof of a house is a truss system and a sheathing on which the roofing material is mounted. Insulation laid between the rafter legs. In this case, one condition is surely fulfilled: the heat-insulating material must fit snugly to the lateral planes of the rafters so that there are no gaps left. Therefore, the insulation is cut in width so that this size is slightly larger than the distance between the two rafters. For obvious reasons, this does not apply to polyurethane foam.

Laying mineral wool

The process begins after the truss system is installed.

-

From the top of the rafters, a waterproofing film is laid across the strips. Begin with the eaves, then milestones to the ridge. The upper bands are laid on the lower with an overlap of 10-20 cm. The joint is glued with self-adhesive tape. Attach waterproofing to the rafters with a stapler and staples.

-

Fill over the rafters (along) slats section 50x50 mm. This is a counter grille that will create a ventilation gap between the heat insulation cake and the roofing material.

-

Transversely install the crate with a certain step, corresponding to the type of roofing.

-

Mounted roofing material.

-

The remaining insulation processes are transferred under the roof to the attic.

-

Between the rafter legs the mineral wool mats are laid.

-

The top is covered with a vapor barrier film that is attached to the rafters just like a waterproofing top.

It might be interesting! In the article on The following link read about how to insulate the floor in a private house: the secrets of thermal insulation.

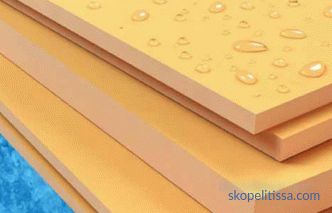

Laying polystyrene foam plates

The installation technology for this thermal insulation material is exactly the same. The only thing you can refuse from the vapor barrier. Expanded polystyrene, as can be seen from the table, the material is non-hygroscopic, so he is not afraid of high humidity.

I would like to add that it is not always possible for the plates of the PP to fit together exactly right next to each other. Therefore, small gaps are foamed with mounting foam. But it is better to use a special sealant for this. It looks like foam, but does not expand in volume, like the latter. And does not change its characteristics throughout the life of the product.

Applying polyurethane foam

To use polyurethane foam to insulate the roof of a house, you need special equipment . This material is made on site from two components that are mixed in a special container. The components themselves come in different barrels. The mixture is fed to the slag under pressure.

As for the technology of insulation, then, like the first two cases, it is necessary to carry out all operations before moving inside the attic. After that, the foam is simply applied to the roof system and roof covering, which is covered with waterproofing film from below. In the end, the applied layer is obtained without gaps. For roof insulation is a big plus.

Comparison on ease of installation

You can say one thing: polyurethane foam is a material that can be applied just if, of course, there is the appropriate equipment. The application process takes place quickly, there is no additional fit of the material, a small roof can be insulated in a few hours. Mineral wool and polystyrene foam are the same in terms of technology and installation speed.

Comparison of insulation in the video:

It can be interesting! In the article on the following link read about the insulation of the foundation with polystyrene foam : history, production and material properties, features of its application.

Conclusion on the topic

Having dealt with roof insulation - which is better in price, in terms of thermal performance and other parameters, it can be concluded that all three of the marked materials differ from each other greatly (though in different positions). Which one of them to choose - no intelligent specialist will advise in absentia. Just consider the criteria that you think is important for your home. Although, as practice shows, many consumers in the basis of choice still invest price indicator. And here is the lead foam polystyrene and mineral wool.

Rate this article, we tried for you