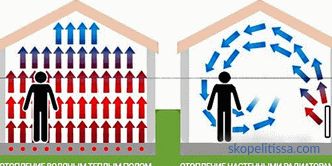

A heating system is a must for every home. Choosing a quality and efficient system, you must first select its type. Many experts believe that it is a floor heating system that can create a comfortable temperature in the room. The peculiarity of this technology lies in the fact that first of all the floor surface and the cold air layers near it are heated. Gradually heated, the air rises, and the temperature in the room increases.

The difference between heat distribution with standard heating and warm floor is

Experts say that the convector and the battery have a common drawback - a relatively small heat exchanger surface. The rapid increase in temperature increases the speed of air flow. It often accumulates a lot of dust. But the warm water floor in a wooden house is characterized by a smooth and large heat transfer area. Due to this, it is possible to use a relatively low operating temperature - up to 55 ° C. This principle of operation reduces the air flow rate.

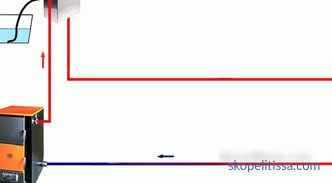

Most often, our compatriots install in the house a heated floor from a gas boiler. Most heaters are characterized by the same principle of operation. They differ in working temperature and location.

The gas boiler heats the water that moves through the pipes and heats the floor

A variety of heating systems

Practically Autonomous equipment is used for heating each house. All warm floors can be classified according to various criteria :

-

principle of operation;

-

type of boiler;

-

coolant.

In individual houses, a boiler can be installed, which uses :

-

solid fuel for its operation;

-

diesel;

-

gas;

-

electricity.

In the heating system the heat carrier may be :

-

air;

-

water;

-

electricity.

By the principle of operation, all underfloor heating can be of infrared or convective type.

To make a film underfloor heating, a special film with heating elements

pasted on it is placed under the floor covering. Each of the above types has its advantages and disadvantages. All of them must be calculated at the design stage. At the same time, experts take into account many different factors.

The most common, affordable and cost-effective in our country is gas heating.

When arranging a heated floor, take into account the characteristics of the material from which the structure is made. For example, a tree is characterized by a small indicator of thermal conductivity.

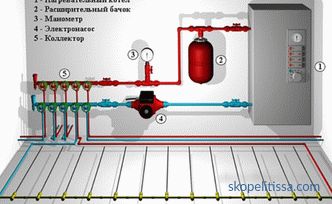

The device of a heat-insulated floor with the liquid heat-carrier

As we know, often, in private houses there is a centralized gas supply. Many install double-circuit boilers that provide hot water in the pipeline. In this situation, as the coolant is better to choose water. But if you do not live in a country house, but only come for a weekend, antifreeze will be the best coolant. In this case, you do not have to flush water from the system and pipes.

There are 2 types of heating system with a heat-transfer fluid: open and closed. The difference between these types lies in the design of the expansion tank.

Open-type expansion tank in the heating system

On our website you can find contacts of construction companies that offer home insulation services. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

An open-loop system consists of a tank that communicates directly with the atmosphere. During heating, the volume of fluid increases. It can be compensated in a simple way - add the required amount of water to the container. But the closed loop system is characterized by a special design of the expansion tank.

Heat-insulated floor with heat-transfer fluid includes:

-

boiler and circulation pump;

-

expansion tank and Mayevsky's tap;

-

distribution unit and safety valve;

-

pipelines.

The water in the heating system is constantly heated by the boiler, which keeps track of its temperature. The heated water enters the main collector, and then - into the distribution unit. Here there is a uniform distribution of warm water in all pipes in all rooms. Due to this, the temperature in the whole house will be the same. Installation of water floor heating in a private house should be performed by a specialist.

Expansion tank of the closed type in the heating system

Pros and cons of using water floors

Compared with radiators and convectors, water warm floors have many advantages :

-

comfort;

-

thrift;

-

aesthetics;

-

safety.

A warm floor allows you to warm the entire area of the room evenly, creating an ideal temperature for human health. There are no drafts on this floor, it is comfortable to play with children on it.

Due to the low coolant temperature, energy consumption is reduced by 20−30%. By installing such a heating system in large rooms with high ceilings, you can save up to 60% by heating the air only 2.5–3 m in height.

This type of heating allows you to carry out various projects for redevelopment of the room. There are no radiators that so often spoil the look.

Eliminates the possibility of injury or burns in contact with the coolant. Therefore, this heating system is safe even if there are small children in the house.

A heated floor can always be adjusted to a comfortable temperature

The disadvantages include:

-

cannot be used on landings;

-

time-consuming installation of the structure;

-

probability of pipeline leakage.

It can be interesting! In the article on the following link read about the subfloor in the frame house.

Used types of pipes

Metal-plastic and plastic pipes can be used for floor heating equipment. Many plumbers positively evaluated pipes made of cross-linked polypropylene. They are characterized by a high degree of tightness, resistance to deformation and good thermal conductivity.

When choosing pipes for installing underfloor heating, carefully study their technical characteristics. In particular, pay attention to the suitability of the material for use in heating systems. Be careful, because some unscrupulous vendors may sell pipes for plumbing. As a result, the floor heating system will be ineffective. Therefore, pay attention to the markings on the pipes. Indicators to be oriented when choosing pipes for installing a heated floor:

-

linear expansion (up to 0.025 mm / m);

-

thermal conductivity (more than 0.43 W / m ° C).

You can find out the required number of pipes, taking into account the diameter of the material and the step of its installation.

When selecting pipes for a heated floor there are a number of nuances, therefore it is better to entrust the choice to professionals

Electric floor heating device

The essence of the electric floor heating is that the conductors are heated, which are under load. And the level of temperature increase depends on the resistance of the material. To date, there are 2 ways to install such a heating system: cable and film.

Cable underfloor heating has a lot in common with water. Just instead of pipes with warm water, they lay an electric cable under the floor. It heats up by passing electricity through itself. To control such a heating system is simple - it is necessary to adjust the periods of power on and off. In other words, when the room reaches a certain temperature, the system shuts down and turns on when cooled.

It might be interesting! In the article on the following link read about the floor of a frame house on screw piles.

Pros and cons of electric floor heating

Electric floor heating in a private house has a large number advantages . The main ones are:

-

reliability (no leaks can appear);

-

noiselessness;

-

aesthetics;

-

long life;

-

uniform heating throughout;

-

simple operation.

Heating pipes

Disadvantages this heating system:

-

the presence of weak electromagnetic radiation (harmless and safe for humans);

-

high power consumption.

Features of the installation of a heated floor in a wooden house

In a wooden house, the installation of a heated floor should be carried out correctly. After all, wood has its own characteristics that must be taken into account. Remember, the temperature of the heated floor in a wooden house should not exceed 30 degrees. Otherwise, the wood will dry out, which will lead to premature release of their material.

A warm water floor in a wooden house, like an electric one, needs to be equipped during the construction phase or during a major overhaul, otherwise the cost of installation will be very high.All work on the installation and connection should be carried out only by specialists. Please note that the subfloor must first be warmed.

When equipping an electric floor heating, it is recommended to use armored cable with outer metal braid. It should also be borne in mind that the cable can damage rodents. And this braid protects the cable from various external influences.

Only during the construction phase, the installation of a heated floor will not result in additional costs . Pre-installed on them devices that protect the wiring from a short circuit.

Having decided to install a warm water floor in a wooden house with wooden floors, it is necessary to level the surface well. The heating pipes are laid in a special box, which is subsequently covered with boards. The box is made of wood, drywall or other material that will absorb moisture well. After laid laminate.

Insulators of the system

The construction of a heated floor needs the use of insulant. Experts do not recommend choosing foam. After all, it is in direct contact with a warm floor, the temperature of which can reach 70 ° C. At the same time, the foam quickly ages and releases toxic gas. Better pay attention to perlite and ecowool, laying them between the beams.

Using mineral wool, it must first be wrapped in a vapor barrier. After all, the warm air through the gaps can make its particles in the room from the underground space.

Do you need a heater under a heated floor? See in the video:

or electric

No one can answer this question exactly. If you are interested in saving construction structures (the cost of materials and work), then it is better to pay attention to the electric floor. If we compare the cost of energy, it is better to pay attention to the device of warm water floors in a private house.

No matter what type of flooring you choose, remember that the thickness of the wooden flooring over a warm floor should not exceed 21 mm. Wood is a good heat insulator, which significantly reduces the work of the heating system.

For a visual comparison between water and electric underfloor heating, see the following video:

It might be interesting ! In the article on the following link read about the floor for the gazebo.

Conclusion

Remember, the construction of high-quality and effective underfloor heating of any type must be carried out by highly qualified specialists. In this case, you should use high-quality equipment. Do not save on materials, because when a leak is detected, you will need to open the floor and completely change the pipeline or repair the electrical cable.