A beautiful and well-kept house is the concern of any owner. This is especially true for those who built a house of cellular concrete or frame technology - such buildings need lining. The traditional wet finish (plaster, paint) is not liked by everyone, moreover, it does not meet the modern requirements of “good walls” (maintaining the necessary wet-temperature conditions). Wood trim, even if properly cared for, is short-lived. Facing with bricks creates a serious load on the foundation and the wallet (not everyone can take it).

The modern market offers a worthy alternative to the classical methods of exterior decoration of the house - artificial lining, facade panels. Among the many colors and textures popular wall panels for exterior home decoration under the brick. Facing with such material gives the house a complete look and at the same time protects the facade from the destructive influence of Mother Nature.

Types of facing materials

Panels used for facade cladding are divided into types according to the structure:

-

Single-layer. The thinnest and lightest, which are suitable for decorative finishes. If it is necessary to warm the facade, they are mounted together with a warming layer.

-

Double Layer. They have a lower (inner) insulation layer.

-

Three-layer. Sandwich panels consisting of two outer layers, the gap between which is filled with insulation.

The size of the front materials are:

-

Composite. Small size is convenient for combining colors and textures.

-

Solid. Due to its large size, it is easier to work with them (labor costs and installation time are reduced).

Also panels are classified by application (socle and front) and by material.

Advantages and Disadvantages of the Artificial Facing

Facing the Facade of the House with Panels it turns it into an elegant building under a brick and therefore enjoys consistently steady demand. The panels are widely used for decoration of walls, corners of the building and basement: they trim the fragments of internal partitions and fireplaces. Each species has its own advantages, but there are also general advantages:

-

Aesthetic. Panels imitating brickwork give the house a nice looking, respectable look.

-

Economic. Artificial lining of a house with brick panels is cheaper than natural analogs and has a long service life (25-50 years).

-

Thermal insulation. The panels help to improve (to varying degrees) the thermal insulation of the interior.

-

Protective. Serve as reliable protection (especially for structures made of wood and aerated concrete) from moisture, solar ultraviolet radiation and temperature changes. Prevents surface corrosion and mold.

-

Mounting. Facing with front panels on a frame construction is carried out year-round: when mounted on glue, temperature and air humidity matter. The panels have a simple installation system - the work is faster and easier than laying the finishing brick. Waste does not exceed 3-5%.

-

Operational. The brick panel is environmentally friendly, has good sound insulation characteristics. Decorating a house with brick panels can withstand all weather conditions, it does not crack and does not fade.

The disadvantages include:

-

Plastic components are flammable, emit toxic gases in the fire.

-

Irreversible deformation (from impact or pressure) of some species.

-

Facing certain types of panels is very expensive (but still cheaper than real facing bricks).

-

In case of installation, in many cases, you cannot do without the services of professionals - otherwise the violation of technology will affect the durability of the facade panels.

Facade materials for brick: overview

On our site you can find the contacts of construction companies that offer the service of finishing and insulation of houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

The appearance of the facade elements does not allow distinguishing them from ordinary brickwork. Depending on the material of their manufacture, they are divided into:

Plastic

Plastic panels under a brick can effectively emphasize any style, from classic to high-tech. They belong to the budget option and are made from polymeric materials. Details have a small thickness and need an additional layer of heat insulator.They have common qualities:

-

lightness and mechanical strength;

-

moisture resistance and frost resistance;

-

service life is 20 years.

The most common types of plastic products are:

-

Acrylic facade panels. They are minimal in thickness, lightweight and ideal for buildings on a light foundation. The material is non-flammable, it can be mounted both on the batten and directly on the wall. In general, the positive impression is damaged by the fragility of acrylic - it is poorly able to withstand mechanical loads (it bends when struck), and in the cold it can burst.

-

Vinyl front panels (two-layer PVC front plates). Durable bottom layer does not allow the material to deform when temperature fluctuates, decorative top repels dirt and protects from sunlight. Such an imitation of brick for exterior decoration of the house is demanded due to its design - reliable connecting locks.

The market has a large selection of plastic facings with a pattern of brick. Textured versions are offered (worn, old, torn brick), allowing to create unusual, memorable patterns when finishing. Due to large collections from different manufacturers and various methods of decorating the house receives an individual look, corresponding to the chosen style.

Fiber Cement

The panels are used for both facade cladding and interior design. Fiber cement is a composite (contains several components) material, which includes cement, mineral fillers and cellulose fiber. All components are mixed, pressed and dried. On the monolithic base obtained, a finishing and protective layer is applied.

Features of fibrous cement products include:

-

Frost resistance. Material withstands 100-150 freeze-thaw cycles.

-

Incombustible.

-

Flexural strength.

-

Environmental friendliness. Can be used in interior decoration.

-

Lightness. Material is lighter than porcelain stoneware.

-

Moisture resistance (water absorption: 7-20%).

It can be interesting! In the article on the following link read about the facade stone.

Clinker finishing plates

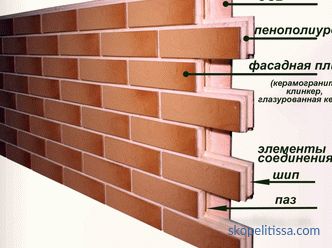

The clinker thermal panels are ceramics for exterior cladding - they allow you to get an immaculate facade. Composite material not only decorates, but also warms the walls. It consists of:

-

Heat insulator. May be foam, mineral wool or foam plastics.

-

The front (decorating) surface. Natural material - clinker tiles for bricks, ideally copying a brick wall.

-

Base. A layer exists in some views and is intended to facilitate installation.

The clinker panels have many advantages:

-

A large selection of showy colors and textures. The material accurately reproduces the brickwork. Many collections convey the aesthetics of an untreated, sawn or aged surface.

-

Easy installation. They are attached with glue. Additionally, the panels are fixed between themselves with locks and screws (holes are provided).

-

Strength. The clinker facade panels are guaranteed to last 50 years.

-

Persistence. Panels made of high-quality clay with subsequent annealing do not burn out or absorb water.

-

Easy for . The surface is cleaned with water from a hose.

Facade panels trimmed with clinker tiles have one drawback - considerable weight. This is a limitation for buildings with a light foundation.

Polymer sand

The material for polymer sandwich panels is a mixture of polymer and fine sand. The lined facade naturally copies natural brick. Finishing the facade with polymer sanding parts is beneficial for several reasons:

-

Low cost. Polymer sand plates - one of the most budget options.

-

Easy installation. The parts are light and flexible: they are fixed on the wall with glue, additionally connected with screws, projections and grooves.

-

Diversity. A decent selection of colors and textures. The seams are often covered with fine-grained stone chips that improve the appearance.

-

Strength. The panels are clad with both facades and plinths.

-

Incombustible. The panels are marked self-extinguishing, they include a flame retardant.

Porcelain tile

The material is obtained after pressing and annealing the clay at a temperature of 1200-1300 ° C. Adding mineral pigments stains it throughout the mass. The properties of porcelain are:

-

Durability. The manufacturer guarantees 50 years of operation. Recall that the burnt clay amphoras have perfectly survived a couple of millennia.

-

Strength. The material perfectly resists shock loads, abrasion and the desire of children to scratch it with a nail.

-

Low hygroscopicity. Hardened clay does not absorb moisture and therefore is hardy.

-

Resistant color. Thanks to a special technology, the color does not change when used in any conditions.

Facade granite is a heavy material. For cladding the facade it is hung on a reinforced metal frame or put on high-strength glue. At negative temperatures, porcelain stoneware, laid on cement mortar, easily peels off.

It may be interesting! In the article on the following link read about how to design the facade of a low-rise building.

Socle (polypropylene, polymeric) cladding panels

The material for their manufacture are polypropylene resins with the addition of components that improve the strength and durability of color. The basement brick lining successfully imitates natural brickwork - to say exactly what is in front of you, you have to knock on the surface.

The panels have many pleasant properties:

-

Efficiency. Much cheaper than natural materials.

-

Quality. Manufacturer's warranty is valid for at least 50 years.

-

Strength. Not afraid of moisture, mechanical shocks, solar radiation, temperature extremes (does not lose properties from -50 to + 50 ° C).

-

Installation and operation. Facing takes little time, subsequent care is even less. Dirt from the base wash with water as pollution.

-

Lightness. Facing basement panels withstand any foundation. The weight of 1m² of basement plating is 3-5 kg (decorative brick weighs 23 kg, artificial stone - 35 kg, finishing brick - 180-190 kg).

About the principle of installation of facade panels in the following video:

Fiberglass panels

To get fiberglass cladding panels for the facade of the house under the brick using fiberglass with additives of resins. The panels are authentically stylized for brickwork and other natural materials (wood and stone) and differ:

-

Long service life without repair and maintenance.

-

Durability (resistant to sunlight and weather fads).

-

Easy installation (and disassembly).

The disadvantage that prevents fiberglass panels from conquering the market is the price.

Thermoplates or sandwich panels

Each plate has a three-layer structure - it consists of two metal (less commonly plastic) sheets, between which there is insulation. Elements gain strength after joining under high pressure. Their properties include:

-

easy installation;

-

strength and good price-performance ratio;

-

low weight;

-

sound and heat insulation;

-

moisture resistance.

Thermoplates use insulation as a layer of foam or polyurethane foam, and sandwich panels use polyurethane foam, mineral wool or polystyrene foam.

About the process of laying basement panels in the following video:

It might be interesting! In the article the following link read about front lighting at home.

Finishing the facade with panels: mounting methods

Assembling the facade elements resembles a children's puzzle - the parts are joined “in lock”, creating a surface without visible seams. Additionally, the mount is enhanced with screws and clasps (brackets). Several installation methods are widely used:

-

Directly to the facade. The method is suitable if the surface of the wall is perfectly flat; otherwise, it is pre-aligned. Plates are mounted on glue or mortar.

-

On the crate. The method is suitable for most facade materials that are mounted on a prepared frame.

-

Hinged facade. System for ventilated facades.The structure consists of a bracket (attached to the wall with anchors), a set of galvanized steel profiles and cladding panels (hot-melt tiles). Between the wall and the decorative panel there is a place for air circulation.

About testing facade materials for flammability in the following video:

Facade Finishing: installation steps

The technological chain of installation of facade panels is as follows:

1. Surface preparation

On a flat wall, the panels are evenly laid and firmly held; otherwise, moisture will accumulate in the remaining irregularities and voids. For the surface to meet the standards, its:

-

checked by the building level (if the deviation is more than 2-3 cm, the walls need alignment);

-

clean old coatings (plaster, paints), nails;

-

remove protrusions and plaster grooves;

-

process with protective agents (wood);

-

apply a primer.

2. Frame construction

If it is difficult to level the walls, metal or wooden sheathing is installed on them, and:

-

the construction parameters are calculated in advance;

-

sheathing step - 35-45 cm;

-

insulation between the sheathing and the facade of the house is laid.

3. Installation of cladding

When installing facade elements, the following rules are observed:

-

The starting (ejection) plank is installed on the lower border - it aligns the subsequent rows and serves to remove condensate.

-

Parts are mounted in rows, bottom to top; fasten with dowels or screws.

-

A gap is left between the panels and the profiles, taking into account the temperature deformation of the material.

-

The next row is set after the previous one is fixed (and checked by the building level).

-

The joints (seams) are hermetically sealed with a front grout of a suitable color.

Facade materials: prices

A variety of brick wall panels for exterior decoration are presented on the building materials market. The cost of some materials (Moscow region):

-

Plastic front panels. Wall and plinth details with a size of 0.39-0.45 m 2 cost 220-550 rubles. (unit, average price range).

-

Fiber cement panels. The cost is affected by the coating material and filler. Panels with an acrylic protective layer are from 1700 rubles. apiece, with ceramics (Japanese) - from 3100 rubles.

-

Thermopanels. The cost is formed depending on the material of the filler and is 1750-2400 rubles.

-

Clinker tile thermal panels. Cost varies within 1250-2300 rub. / m 2 .

It can be interesting! In the article on the following link read about the finishing of the facade of a wooden house.

Conclusion

To “dress” a house with brick panels is to make it not only more beautiful, but also more functional. Artificial cladding protects and warms walls, increasing energy efficiency at home. Attractive price, excellent performance and easy installation - factors that make the front facing under the brick an ideal solution in most cases.