In modern suburban construction, foam concrete blocks are used with enviable regularity. The material has many attractive qualities - it is durable, easy to process and cheap material. Foam blocks have low (comparable to wood) thermal conductivity and large size, which significantly speeds up construction.

Unfortunately, the foam concrete facade cannot be called attractive. But even if you are a fan of rough, natural surfaces, it is better not to leave foam concrete walls without cladding. Exterior decoration of the house of foam blocks is not only a way to decorate the structure, but also a vital event that prolongs its service life.

Features of foam concrete blocks

To choose the right facing material, you need to understand what features foam has:

-

Structure . The material belongs to the group of cellular concrete and has a finely porous structure formed by closed (not communicating with each other) air cells. The cells are the result of introducing a foaming agent into the initial cement-sand mixture.

-

Relation to moisture . Due to the structure, foam concrete has a low water permeability (compared to aerated concrete, the pores of which form a network of connected channels). Vapor permeability is the same for all cellular concrete, as it is based on the diffusion of water vapor (water molecules are able to overcome the thickness of concrete; this is how the concentration of water vapor in the room and outside aligns).

-

Requirements for finish . Since a wall of foam blocks can breathe (to regulate the humidity in the room), any finish of such a facade should have the main property - not to prevent the release of water vapor. An exterior finish that does not fulfill this condition will trigger the surface destruction mechanism (accumulated moisture will freeze in winter, damaging the cell structure), and the house will experience increased humidity.

Properties of exterior decoration of housing from foam concrete blocks

When deciding how to veneer a house from foam blocks outside, pay attention to the performance properties of facing materials. In addition to the obvious qualities assumed in the materials for facade finishing works - decorativeness, durability and resistance to solar radiation, they must have additional characteristics:

-

Vapor permeability . The main property, if your cottage is built of foam concrete blocks. Improperly organized exterior decoration of the foam block house will violate the humidity control inside the house.

-

Watertightness . Any finishing material (this is one of its purposes) should protect the building from weather vagaries.

-

Frost resistance . The ability to withstand a sufficient number of freeze-thaw cycles without degrading performance.

Acceptable options for facing a foam concrete facade

The following methods are considered valid methods that take into account the characteristics of foam concrete:

-

Installation of a ventilated facade (device hinged lining). Facing is fixed on the crate, between it and the wall is organized a small technical gap. Most often, vinyl siding, fiber cement boards, corrugated board or mounted cassettes are attached to the crate.

-

Brick cladding . Decorative brick, facade stone or tile do not interfere with air circulation if an air gap is left between them and the wall.

-

Plastering . For foam concrete facades, plaster mixtures of special composition are produced that do not impede air exchange.

-

Painting . The walls are painted with silicone paints with high vapor permeability. The surface of the facade is pre-plastered, and the seams between the blocks are rubbed off.

Ventilated facades

This wall covering method was developed in post-war Germany. The system of the ventilated facade includes a supporting frame, which is made of plastic, wood or metal profile (aluminum, galvanized or stainless steel), and cladding materials, fixed at the top. Finishing the house of foam blocks from the outside with a ventilated facade solves several problems:

-

Effective removal of water vapor from the walls.

-

Warming .An obligatory measure for a house being built in the northern region, since a standard wall of foam blocks (block thickness of 20-30 cm) does not provide sufficient energy saving.

-

Protection against natural factors .

-

Aesthetic appearance of the facade.

Cassette hinged facade

Front cassettes are made on CNC hydraulic bending press; the production material is stainless or galvanized steel, aluminum or copper. Cassettes have a wide range of colors, but are rarely used in private construction, losing significantly in value to other facing materials.

Siding in the decoration of a country house

Finishing a house from foam blocks with siding is the simplest solution, economical and therefore popular. The material boasts a significant choice of colors and textures, which greatly facilitates the decoration of the facade. On sale there are various types of siding: aluminum, fiber cement, ceramic granite, composite, vinyl. Among developers, vinyl siding with an optimal price-performance ratio and important advantages is very popular:

-

Resistant to ultraviolet , thereby maintaining the original appearance after prolonged use ( 20-25 years).

-

Suitable for facing buildings with a light foundation .

On our site you can see the most popular projects projects of foam concrete blocks from construction companies represented at the Low-rise Country house exhibition.

-

Uncomplicated and quick wiring .

-

Excellent water-repellent properties .

-

Corrosion Resistance and temperature extremes.

-

Simple care behind the surface - dust and dirt can be easily washed off with water from a garden hose.

The main disadvantage of vinyl siding is its increased brittleness at low temperatures; during frost, it can crack from an insignificant (including wind) load.

The facade is finished with a professional flooring (profiled sheet)

The professional flooring is widely used as a lining for suburban buildings of foam blocks. The material is produced in the form of steel sheets with a profile of a complex ridge shape. The industry produces decking with a decorative protective coating of two types:

-

Zinc . Practical and inexpensive option, which is used for facade decoration, as well as roofing.

-

Polymer . Due to the large number of colors and textures, such a profiling allows the facade to give an individual appearance.

The ventilated facade of the profiled sheet has useful performance characteristics:

-

Resistance to the vagaries of weather and all types of corrosion.

-

Tightness . Bearing walls of foam blocks will be reliably protected from moisture.

-

With a durability and simple care. The professional flooring does not need additional processing (lining, for example, requires periodic treatment with an antiseptic and staining).

-

Fire resistance . The professional flooring does not support burning.

About the finishing of the cottage from foam blocks with siding in the following video:

On our site you can find contacts of construction companies, who offer the service of warming and finishing of houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

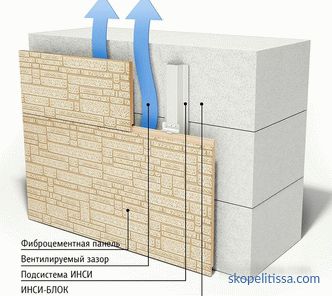

Fiber cement boards (panels)

The main component of the panels is cement (80 - 90%), it is supplemented with cellulose and mineral additives. Due to its durability and environmental friendliness, this material is in demand when organizing a protective facade finish. The basis for the plates is a frame made of metal profile or wooden slats; water vapor is weathered through the gap. The advantages of fiber cement plates are:

-

mechanical strength and incombustibility ;

-

moisture resistance and frost resistance ( 3 times higher than that of a brick brick 1> increase of heat and sound insulation of buildings.

Blockhouse

Blockhouse (board imitating timber or log) allows you to arrange a sustainable exterior cladding housing, a common version of the ventilated facade. The lining of the blockhouse needs to be updated periodically: the wood is impregnated with an antiseptic and fire retardant once every 3-4 years.

Cladding with heavy materials

If you are against the use of polymeric materials in the exterior, you can use another technology. Exterior decoration of the house from foam concrete blocks with heavy materials (stone, brick or tile) is more laborious and difficult to perform, but it has its advantages. The decision on stone finishing is made at the design stage, since in this case the foundation will need to be laid with a 15-20 cm issue along the perimeter of the house.

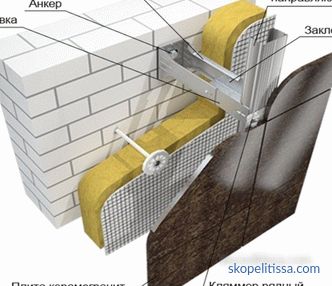

Facing with the selected facial material is carried out simultaneously with the laying of the front wall of foam blocks. An insulation (most often mineral wool) with a windproof membrane is fixed under the finishing layer. An air gap remains between the film and the foam block; metal anchors are used to fasten the cladding to the facade.

About the laying of facing bricks in the following video:

Cladding brick

The brick allows you to do without installing a ventilated hinged system and plastering exterior walls. Produced single and thickened, as well as clinker (high strength) material. The obvious advantages of bricks are:

-

Strength and durability . The brick of brands from M75 to M250 is issued. Resistance to atmospheric precipitation is achieved due to the low porosity of the material (6-14%).

-

Frost resistance . An important parameter for areas with cold and long winters. There is a brick with stamps from F25 to F75.

-

Variety . A wide range of textures and colors. The cladding uses red, yellow, white and brick with various shades of brown. The front surface may be depressed relief, be glazed (coated with a composition based on glass powder, followed by firing) or engobed (coated with liquid colored clay and re-fired).

-

Environmental friendliness . In the manufacture of bricks used natural clay.

The disadvantages of brick cladding are labor-intensive and expensive.

It might be interesting! In the article at the following link read about what you should know when buying a house from foam blocks.

Facing the facade with a stone

Natural stone serves as a high-quality decorative material that allows you to significantly improve the appearance of the house of foam blocks. The most common facing natural stone is limestone and sandstone of various colors, less often use marble and granite. Such a finish will have considerable weight; for it in advance, as for the brick, the foundation is being prepared. The use of natural stone in the decoration of the facade provides:

-

Protection of the construction from external weather conditions (temperature, humidity, solar radiation) and accidental mechanical impacts, environmental friendliness.

-

Attractive appearance of the facade, the ability to support any chosen style.

-

Long flawless operation (at least 40-50 years) and simple maintenance (dirt can be removed with a cloth).

-

Improved sound insulation .

-

Improved thermal efficiency of construction , savings in heating.

Significant disadvantages of using natural stone in the exterior of a country house include .

-

High cost . The quarry where natural stone is mined may be located at a considerable distance. Transporting heavy material can significantly increase the cost.

-

Foundation load . Stone cladding can significantly weight the house. Its weight must be considered in calculating the strength of the foundation.

Thinking about how to sheathe a house from foam blocks outside, many turn their attention to the artificial stone, a material with its own advantages:

-

Smaller (compared to natural stone) porosity , which allows to withstand moisture, mold and temperature changes.

-

Aesthetic appearance , for decorative qualities not inferior to natural counterparts.

The lack of lining the house of foam blocks with artificial stone - low sound insulation and thermal protection.

About the intricacies of applying plaster on the foam block facade in the following video:

Facade finishing with tile

Facing the house from foam blocks not with tiles requires strengthening the foundation, as it is carried out directly on the facade, with the help of a special mixture. Clinker tiles, porcelain stoneware and frost-resistant ceramic tiles are used to decorate the walls.

All materials serve as reliable protection for foam block walls, and their appearance is varied.In the external design they use both colored tiles and imitating ceramic bricks or natural stone. Despite the aesthetics and cheapness, the tile should be used with caution (for partial lining) - foam concrete removes moisture to the outside; this destroys the mixture, which keeps the lining.

Plastering and exterior paints

Facing a foam block country house with plaster is a quick and budget way to protect the facade. The plaster is quickly applied and dries, has a presentable appearance and is excellently combined with other facing materials (for example, with an artificial stone base).

It might be interesting! In the article on the following link read about building houses from foam blocks.

If the technology was not disturbed during the preparation and application of plaster, such finishing will not crack and fade under solar ultraviolet radiation. For the majority of country cottages from foam blocks located in areas with warm climate and mild winters, choose one of the options:

-

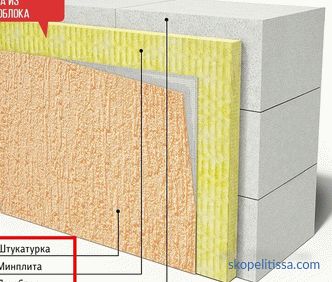

Plastering . Traditional plaster of cement and sand is not suitable. For high-quality protection of the wall of foam concrete are selected mixture with high vapor permeability and low shrinkage during operation. They are composed of adhesives that increase adhesion (quality of adhesion) with a foam concrete surface.

-

Plastering followed by painting . For the painting of the facade of foam concrete, vapor-permeable (silicone) paints are used.

Facade plastering is considered a time-consuming process requiring specific work skills . Plaster is applied in two layers - starting and finishing, the work can be carried out at temperatures above + 5 ° C. Finishing of the external walls of the house from foam blocks goes through several stages:

-

is prepared (cleaned of dirt and dust) facade .

-

The wall is covered with primer , reinforced reinforcing mesh (in places of load - at the corners of the facade, above the openings).

-

A starting (draft) layer of the plaster mix is applied.

-

A primer is applied to the decorative layer of plaster.

-

a finishing layer of paint or plaster is applied to the facade.

The method has indisputable advantages:

-

The plaster for foam concrete is durable and possesses pronounced hydrophobic properties , which makes it possible to secure the facade from external forces of any nature (mechanical and natural).

-

The stucco for foam concrete does not stop the diffusion in the walls of the building, allowing the steam to freely go outside.

-

Set of variants . Plaster can be simple and decorative, colored and terrazitovoy (with the addition of chips from marble, glass, mica).

The disadvantages of plastering the facade of foam blocks include:

-

Need for experience . The process has nuances in the preparation and application of the composition. To make high-quality coverage, we need skills, adherence to technology and tools.

-

Short service life . Over time, the plaster accumulates moisture and loses its protective properties, until the next repair will take place no more than 10-12 years.

-

Sensitivity . If the walls and the base vibrate, the plaster may crack and crumble.

What can not be used for facing the walls of their foam concrete

Exterior finish can not be carried out by materials that prevent diffusion of water vapor. Their use will lead to the fact that moisture will linger on the front surface; thermal conductivity (and heating bills) will increase, and the strength of the facade will decrease.

-

thin slabs of foamed polymers;

-

using concrete and ceramic tiles;

-

classic cement-sand mortar;

-

ordinary paints that create a film on the surface that is impermeable to steam.

The construction technology of foam concrete provides for the protection of the material from contact with water or snow, therefore even a house with a proper lining needs additional protection:

-

Competent device roofs and drainage systems .

-

Organizations subwindow plums and canopies above the decorative details of the facade.

-

Protection of the base from moisture.

It can be interesting! In the article on the following link read about the foundation for the house of foam blocks.

Conclusion

The properties of a foam concrete facade impose certain restrictions on the choice of facing material. Nevertheless, it is large enough, and all decisions are reduced to two options: you will have a country house with a ventilated or plastered facade. If the choice of a specific type of plaster can be postponed until the end of the internal finishing works, then the choice in favor of stone or brick cladding should be made at the design stage of the foundation. When purchasing exterior finishing materials, such parameters as frost resistance, vapor and water permeability, level of adhesion to the base are controlled.