A small barn at the cottage is an object necessary. It can store garden tools, tools, some household items that are not used in the winter, and so forth, so on. Today, many gardeners use wood heating. So the barn is often used as storage for firewood. In this article I would like to talk about the woodshed from the pallets, as a kind of barn. Why pallets are so well suited for the construction of small objects, the savings from this construction, as well as the technology of the construction of a woodshed.

Wooden pallet

Everybody faced wooden pallets. This is a shipping container that is used as a storage unit. It stores the piece goods, store and transport it. In this case, the movement is made using special vehicles.

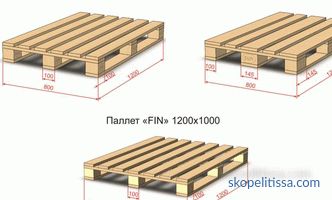

In Russia, pallets are not hosted goods. This means that they do not have specific requirements in terms of sizes. Therefore, different manufacturers have different products with different sizes. But in Europe, these devices have certain standards. But there is no single GOST and in each country the production is treated differently.

For example, the main type of wooden pallets used in Europe have dimensions: 800x1200x144 mm. And in Russia they are called euro pallets. There is another variety that comes from Finland. Her dimensions are as follows: 1000x1200x144 mm. Sometimes the height is reduced to 138 mm.

The most important parameter to which special and strict requirements are made is the carrying capacity. So it should not be less than 1000 kg.

Today, manufacturers produce pallets of different purposes, hence their small classification:

-

Two-way or four-way . The first ones are stands, in which the fork of the loader can come in from two sides . The second is from four sides .

-

Single-Conveyant and Two-Strength . In the first case, these are pallets, the freight stand of which is located on one side . In the second - with two sides , that is, the pallet itself can be positioned on either side.

-

Disposable and negotiable . Everything is clear here, the first ones are disposed of immediately after one use. The second is exploited many times.

For a shed it is better to use double-load, single-paste pallets. They are not inferior in strength to others, but the price of the product is much lower. But since the task is to construct a shed from a pallet, they are also pallets, the best option is used devices. Usually old coasters are thrown into the scrap, many of which are still in good condition. Often this wooden material goes for free.

What is a wood cooker

So, you must first understand the terminology. There are two almost identical structures: woodshed and woodsheds. They differ from each other in that the first is a firewood shed, built on a foundation, which is a separate building. That is, it should not be adjacent to the main house in the suburban area. The second is a light structure, almost a canopy, which is adjacent to the house.

There is another similar term - firewood. This is a firewood basket. It carries wood, it is installed inside the house, where they put firewood for heating the stove, heating and other household needs.

Why do we need wood stove

It is clear that raw wood does not burn well , poorly emit heat, but very well smoke, clogging the stove chimney with soot. That is, there are many negative moments from the use of such firewood. Therefore, they must be stored in a dry place. But in rural areas, where heating is more often based on the use of solid fuel, it can be said about cooking, and kindling of a bath, and even cooking barbecue or barbecue, firewood is produced in large quantities. So, they need a space that is closed on all sides.

So, the requirements of a woodsmith are:

-

It must be in a convenient place . To him should be free approach.

-

Overall dimensions are selected at the rate of stored fuel .

-

In the shed should be thought out the ventilation system . It is impossible to allow the firewood inside the building to be dampened during storage.

-

You cannot allow the to fall on the sun logs. Too much dried wood burns quickly.

-

It is necessary to ensure that the woodsmith fits well into the landscape design of the country plot.

Construction technology 11>

So, it was determined that a woodshed is just a barn. To build it from pallets, it means that we must first determine the dimensions of the building, and then calculate how many pallets will be needed in construction. Immediately make a reservation that the pallets will be installed, as they say, "on the butt", that is, on the butt. In this case, the end face is chosen in which the ends of the beams used as the base of the pallet will be visible. That is, the bars will be placed vertically.

Hence, the width of the pallet in the woodshed becomes its height. And if, for example, a pallet with a width of 1 m is purchased, then at least two pallets installed on top of each other are needed to achieve an acceptable height of the shed being erected. That is, the height of the structure in this case will be equal to 2 m. And the length of the wooden device automatically becomes part of the length of the object being built.

On our site you can familiarize yourself with the most popular small-scale projects garages - from construction companies presented at the exhibition "Low-Rise Country".

For example, the simplest construction of a woodshed is pallets stacked in pairs, and they are also installed one on another. The number of pairs will depend on the size of the structure itself, given that almost all varieties have a standard pallet length of 1.2 m. As an example, you can take a small barn size: three pairs of pallets in length, two pairs in width. In size it will turn out to be 3.6 and 2.4 m, respectively. The area of the internal space will be almost 9 m². And taking into account the height of 2 m, this will be a rather serious volume - 18 m³. Such a quantity of firewood will be enough for the whole winter for a family of several people.

Now we turn to the technology of building a barn from pallets. And at once we will make a reservation that there is no standard technology. But the only thing that unites many varieties is the frame construction of the structure. Therefore, in the first place they construct a frame, and already pallets are attached to it.

Our site contains the most popular house manufacturers presented at the exhibition and offering services : installation of metal structures (sheds, greenhouses, etc.), extensions to existing houses, design and construction of small architectural forms: gazebos, grill houses, sheds, etc. You can directly communicate with representatives by visiting the Low-Rise House exhibition .

The simplest version of the frame structure is the installation of vertical pillars. For this, bars with a cross section of 100x100 mm are usually used. They are driven into prepared wells, after conducting waterproofing measures. The last is the coating of the edges of the bars, which will be buried in the ground, with bitumen mastic. To enhance the often carry out wrapping with roofing paper in two layers.

The supporting legs of the frame are set strictly vertically. Taking into account the height of the shed and the length of the end, which is buried in the ground, calculate the length of the bore posts. Usually the size of the dug end is at least half a meter.

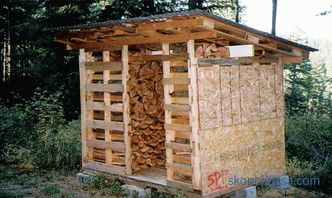

After the racks have been prepared, it remains to mount the pallets. For example, this can be done as shown in the photo below. Pallets are put on racks, attached to them and fastened with long screws.

The described installation method is considered one of the most reliable. That is, the shed assembled by frame technology is a sturdy, stable and reliable structure. But there are other options that are equally reliable. Only they are not going to frame technology. It uses reliable fasteners, through which the pallets are interconnected in one single wall.

For this purpose, the pallets joined in the same horizontal row are interconnected with long M12 bolts. Therefore, in the bars, which are the carrier base for the pallet, make through holes with a diameter of 14 mm. It is necessary to make holes so that when docking the pallets, they coincide with each other. And since in each pallet there are three pairs of support bars, there will be three strong joints that guarantee the reliability of the constructed structure.

It is possible to conduct the connection with direct suspensions, which are used in the construction of suspended ceilings or ventilated facades.

The video shows just such a construction option of a shed, where pallets and direct suspensions are used:

Another option. It is connected with metal pipes. It is somewhat similar to the frame structure, but the approach to the fastening is completely different. To this end, pipes with a diameter of 32 or 40 mm are driven into the ground at the junction of the pallets.Electrically welded to them are a couple of plates in which holes are pre-made for fasteners. That is, two pallets in the same horizontal row are fastened through the plates with self-tapping screws to the same pipe support.

It may be interesting! In the article on the following link, read about the dwelling unit with a drovnik: the process of building a building.

Roof and other elements

Let's start with the front door. For her, specially set the rack. This is usually wooden beams, which are dug into the ground or attached to the base in any way possible. In this case, the racks are required horizontal jumper.

Now, as for the roof. Usually for a small structure it is single-pitch. Drovyanik in this regard is no exception. Here the main thing - just to observe the angle of the roof. It can be made by installing a wooden farm on the front side of a small barn. In fact, it is a rectangular structure, assembled from bars of small section. It is installed on the front side of the erected structure and is attached to the pallets in various ways, for example, with long nails or self-tapping screws.

Then the truss legs are laid, the sheathing on them, and the roofing material on top. After that, the farm is closed with sheet material: plywood, OSB boards, corrugated sheet metal, sheet metal and so on.

It may be interesting! In article on the following link read about the cost of a house in the regions - trends and market dynamics, the impact on the price tag of the political and economic situation.

Woodwork plating

So, the woodshed is built. But before the start of its operation there is time, because the erected structure is a sieve. So, it must be sheathed outside with sheet or slab material. There are lots of options here, the main thing is to accurately fit the constructed object into the landscape design of the suburban area. Usually pick up the decoration on the exterior design of the main house.

Structural nuances

A very important point is the foundation of the woodshed. It should not only be durable, it should be dry. Therefore, most often in the barn poured concrete floor, besides, it must be above the ground on which the barn is being built. This is in case of rain and snow. Water should not get inside the building.

Often the floor is constructed from the pallets themselves. But in any case, they form a solid foundation. Sometimes the shed is set on a column base. Then, for this purpose, wooden pillars are assembled from posts with a section of 100x100 mm. And already on them are laid and fasten the pallets themselves. In the photo below just such a barn is shown.

The roof must be erected with overhangs 30-40 cm long. This is a time-tested protection from natural precipitation. As for the roofing material, there are no restrictions. But more often they use slate or decking, less often shingles, under which it is necessary to lay a continuous crate. And this additional cash costs.

The video shows how to construct a simple wood-fumbler from wooden pallets:

It may be interesting! In the article on the following link read about the wave-house in Finland: a project based on the contours of ships and airplanes.

Conclusion on the topic

Probably, we must pay tribute to our compatriots, who sometimes use public service objects from the rubbish. And in this regard, wooden pallets are no exception. Even unsuitable, which are usually used as firewood, suddenly turn into a good building material. The main thing - to include fantasy.