Today we will tell about how to make a viewing hole in the garage. For many motorists, this is a necessary element of a garage building, so many of us are trying to save money, which is why some preventive work related to the car is carried out independently. Immediately we must make a reservation that with the seeming simplicity of the construction of the viewing pit, it is not so easy to build it. Therefore, most garage owners prefer to invite experienced craftsmen to get a guaranteed high quality of the final result. But to guarantee one hundred percent, you need to know the technology of the construction of the garage pit. Therefore, read the article, remember everything, and it will be a guarantee that the masters will not deceive you.

Planning the construction of the inspection pit

There are two situations when building a pit in the garage:

-

in the construction of only ;

-

in the already operated .

The first option is simpler, because nothing prevents you from digging up the soil for the size of the intended structure. To do this, you can even use the services of an excavator, thereby speeding up the process itself and move away from labor-intensive earthworks.

But both situations happen often, so let's deal with them separately. But first we will tell about the size of the pit in the garage under the car.

Dimensions of the viewing pit

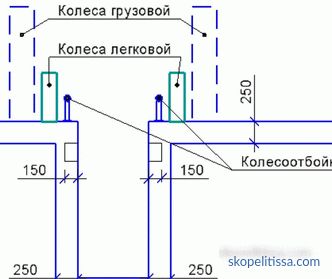

The basis of the dimensions is the automobile base, or rather, the distance between the wheels of your car, both in width and in length. But there are minimum width parameters, which are often taken as a basis. This is 80-85 cm. As for the length, they add 1 m to the length of the car. Although it is necessary to pay tribute to the fact that for ease of use of the inspection pit many do not stop at this size, therefore in the garages you can find holes up to 6 m long.

Now with depth. It is clear that the growth of the owner of the garage and should be this dimension. At the same time, he must reach up to any part or assembly with his hands. But experts recommend deepening the inspection pit to 2 m. And even if a person is small, you can always install a stand or a flooring on the bottom. True, this is not always possible. Much will depend on the level of groundwater flow. If it is tall, for example, 1.2-1.5 m, then you can forget about the pit.

These were the overall dimensions. Now about the size of construction. For obvious reasons, the pit itself is dug under a hole more. This is due to the fact that for the formation of the structure itself it is necessary to equip the structure. And for this, it is necessary to lay a cushion with a waterproofing on the bottom and pour it with a screed. The walls are assembled from blocks or bricks or poured into the formwork with a monolithic structure. All these materials require space without taking into account the chosen dimensions of the viewing structure.

Therefore, the excavation is excavated to a width equal to the width of the viewing pit, plus the thickness of the walls, plus 30 cm. The length is calculated in the same way. Depth is the thickness of the cushion, the thickness of the screed and the waterproofing layer, plus 1.8-2.0 m.

On our website you can familiarize yourself with the most popular projects of garages and other "small forms" for a country house - from construction companies represented at the exhibition "Low-Rise Country".

Technology of the construction of the observation pit

We will not tell you how to build a garage with a pit that is being built. It is not so difficult. We will tell about how to make a viewing hole in an already operated garage.

Digging out a ditch

We assume that you have decided on the size. They are applied to the floor in the garage, for example, marking with chalk. The main requirement - the pit should be located in the middle of the garage building.

A sand and gravel pad and soil are removed from the resulting opening with shovels. The walls and bottom of the pit with shovels align to the maximum. This is a hard work that can take two days. Although much will depend on the composition of the soil under the structure and the activity of the masters. There is one advantage in the construction of a viewing pit in a operated garage. The construction site is under a canopy, so that the rain in this case is not an obstacle.

Ventilation of the inspection pit

The error is made by someone who does not think about ventilation system. But its purpose is not only to remove moist air. Smell smells from oiled rags, gasoline will fill a small space quickly, gradually moving into the garage itself.So it is better to spend a little time and money, but to erect ventilation.

In essence, this is a plastic pipe with a diameter of 100 mm, which is taken outside the building. To do this, dig a horizontal trench, which is derived either under the foundation, or through a wall. Sand is poured into it and a pipe is laid with the output above the roof of the garage. The lower end should be located at the bottom of the pit.

Arrangement of the viewing hole

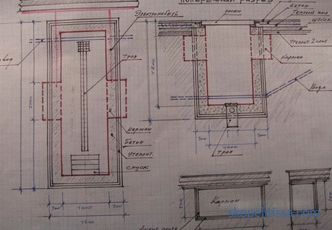

So, we proceed to the main works related to construction of the pit itself. First of all, prepare the bottom :

-

Fill with a layer of sand 15-20 cm thick, which is tamped with watering.

-

Crushed gravel of medium or fine fraction 10 cm thick, which is also tamped.

-

The waterproofing of the entire pit is carried out: floor and walls.

On our site you can find contacts of construction companies that offer the service of designing and building garages and other "small architectural forms" for a country house. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Waterproofing

Waterproofing the inspection pit in the garage is a crucial stage. So understand this process.

For carrying out waterproofing works use rolled material. This can be a plastic film with a thickness of at least 0.2 mm, laid with a sleeve. For this purpose, roofing material or modern waterproofing materials based on bitumen are used.

The strips of waterproofing are laid in strips from wall to wall with overlap relative to each other with an offset of 10-15 cm. Bituminous products in places of overlap are fixed with bitumen mastic. The polyethylene film is sealed with self-adhesive tapes. The photo below shows the version with polyethylene. Please note that the edges of the waterproofing wind up outside the pit and press down with a load.

Forming the floor and walls

Prepared bottom is poured with a screed 3-7 cm thick. No reinforcement cage should be laid into it, because the structure is not subjected to loads, except for the weight of the person. Therefore, the main focus is the construction of walls.

As mentioned above, there are two options:

-

use bricks or blocks;

-

build a monolithic structure.

In the first case, the block wall material is laid around the perimeter of the prepared excavation, laying the elements of the wall with a sash. That is, with a shift to half a block or brick. For bonding using conventional masonry mortar with a formulation of 1: 2 (cement-sand).

If a monolithic structure is erected, then formwork is assembled for this. Make it of boards, plate or sheet equal and strong materials. For example, from sheet metal or corrugated board, plywood or OSB boards.

The main task is to assemble the formwork so that it does not disperse under the action of a sufficiently large weight of the poured concrete. If the soil under the garage is clay, the formwork is mounted as a single layer of fences from the outside. The wall of a ditch covered with a waterproofing itself will be able quietly to sustain any loadings. If the soil is sandy, loose and fragile, then the formwork is installed in two layers, leaving between them a space for pouring concrete solution.

Concrete is poured at a time, without leaving the next day. A break can be between fills, but not more than 4 hours. Look at the photo, this is how the formwork with concrete solution poured into it looks like.

It can be interesting! In the article follow the link read about the basement in the garage.

It is recommended to lay the reinforcing frame in the form of a grid of reinforcement with a diameter of 6-8 mm in the concrete walls. The grilles are installed along the walls so that they are in the middle of the formwork space. On adjacent walls, the frames are tied together by knitting wire.

A week after pouring the concrete solution, the formwork is removed. But concrete gains its strength only after 28 days. After that, you need to surface the structures primed and think over the type of finish. The best option is ceramic tile. She is well washed. But you can paint the pit, plastered or revetted with brick. As for the pits of bricks or blocks, then it must be plastered, then whitened or tiled.

In principle, we can assume that the construction of a viewing pit in the garage is completed. It is necessary to add that often along the perimeter of the structure flush with the floor is placed a restrictive structure. This is a steel corner, welded in the form of a rectangle, equal to the size of the viewing pit. It is attached to the pins or studs laid in the process of pouring concrete.

Plastic models

Today, manufacturers of plastic and plastic materials offer ready-made plastic pits for the garage. We must pay tribute to this type of product, which has simplified the construction of inspection pits. There are more and more offers on the market every year. There is not only a wide range of sizes, but also a variety of raw materials, and prices differ considerably.

There is no need for waterproofing for the finished excavation. The main thing is to lay a good sand cushion and fill the space between the walls of the excavated recess with sand and a plastic product.

To help you understand what is being said, we suggest watching a video that describes one of the models on the market.

The following video is about the pitch arrangement in the garage:

may be interesting! In the article on the following link read about the project of a modern chalet in Les Houches.

Conclusion on the topic

So, we have disassembled the topic - an inspection pit in the garage (dimensions and construction rules). How difficult is the whole construction process, judge you. But keep in mind that the exact dimensions of the pit - the key to success. They made the pit smaller - it will be inconvenient to be in it. If you have done more, especially in width, then there is a chance that the car will simply not be able to fit on it.