Modern cottages made of glued laminated timber are increasingly in demand, as this material guarantees reliable, durable construction with a good aesthetic appearance. Buildings from a bar allow the most different planning, they can be under construction both on standard, and on special projects. When building houses from turnkey glued timber, projects and prices depend not only on the material used, but also on the building plot and customer requirements.

Glued laminated timber is popular because of its special structure: it is made of thin lamellae, bonded to each other with glue.

Manufacturing techniques for laminated laminated timber

Most used raw material for creating glued laminated timber - pine and spruce, sometimes used for this cedar and larch.

First, logs are cut into boards of the required size and dried. Their moisture content as a result of drying is much lower than that of a solid log, because boards are much easier to dry.

Then the dry boards are examined for the presence of visible defects that are fixed. Next, the finished boards are treated with flame retardants and antiseptics, and planed. From such, called lamels, boards, and the bar is made. The number of lamellas varies from 2 to 5, which allows you to create a bar of different thickness, maximum - 250 mm. To connect the lamellae used waterproof very strong adhesives. Another property of laminated veneer lumber is that when gluing, the direction of the wood fibers, referred to as annual rings, in the lamellae must be located in different directions. Due to this, glued laminated timber will be much stronger than solid timber. With a decrease or increase in humidity, the material does not lose its shape, and in addition increases the sound insulation properties of the walls of a building.

The main steps in the production process of laminated laminated timber:

-

Drying boards, obtained after cutting logs.

-

First trimming of the boards.

-

Sawing up the boards.

-

Detection of defects and flaws.

-

Elimination of defects.

-

Splicing boards along the length.

-

Calibration of the slats.

-

Applying the adhesive mixture on the slats.

-

Gluing lamellae.

-

Calibration of the glued bar

-

The trimming of the bar in length.

-

Processing of blanks.

What are the projects of houses from glued timber

A wooden house measuring 8 by 8 meters is the most common type in the construction of private country houses, because it has a sufficient area, has a beautiful aesthetic appearance and at the same time small construction costs. Such a building is compact and does not occupy a large area on the plot, allowing you to split the garden or equip a recreation area on the saved meters of land. You can build a house of different types of laminated veneer lumber, for example:

-

two-storey,

-

mansard,

-

with a terrace.

Construction companies are developing low-cost one-storey houses from a bar, in various architectural variants - from the classic to the cutting-edge high-tech style.

One-story houses have a convenient layout for families where there are small children and the elderly. All necessary zones are located within the same floor, and in such a building the whole family will always be close by.

Glulam laminated houses with an area of 100-200 square meters. m strong and durable, well-proven in operation. They have an excellent appearance and do not require extra expenses for finishing, because the smooth surface of a wooden bar is beautiful in itself.

The layout of the house with an area of up to 150 m has the ability to include a variety of technical solutions. In such projects of houses there are not only living rooms, but also rooms for recreation, billiard rooms, gyms, children's rooms.

It is possible to create a smart project of a status private house with an area of 200 m or more, which will be a strong and reliable ancestral nest for several generations of a family. Residential buildings with an area of 200 to 300 square meters. I guarantee comfortable permanent residence and large families in them and correspond to the wishes of the most demanding customers who care about their status and care about the convenience and health of loved ones, the environment and safety at home.

On our site you can familiarize yourself with the most popular designs of houses from glued timber from construction companies, presented at the exhibition houses "Low-rise Country".

Advantages of houses from a bar

Today it is known and proved by scientists that living in a wooden house has a positive effect on human health.

Timber combines all the advantages of logs.It is very convenient to work with him, this material allows you to accurately connect parts, to achieve perfect smoothness of the walls and significantly reduce the cost of finishing.

The construction, because of its lightness, does not require the construction of a massive foundation.

Main advantages:

Glue-laminated houses and cottages have high strength compared to erected log cabins made of solid logs, due to the special production technology of the material. Wood fibers are in opposite directions when combined, which causes high strength, and prevents the deformation of wood as a result of environmental exposure.

Ecological and safe glue is used for gluing timber, which not only firmly glues the lamellae, but also works as an antiseptic.

Least short building time. Considering the laying of the foundation, the decoration and the work of six construction specialists, such a house will be built in 2.5 months.

These buildings have excellent thermal insulation due to the dense assembly, and the use of a compactor. At the same time, tightness of rooms is saved and the possibility of any draft is excluded, which significantly reduces heating costs in the autumn-winter season. Insulation in such houses is often subject to the floor and roof.

Lower costs during the stay - the house from the bar does not deform, does not crack and is not threatened with distortion.

Stylish and beautiful appearance - the bar gives the walls evenness, sanding, painting and varnishing results in a stylish exterior and interior.

Disadvantages of buildings:

The main disadvantage of the structure is expensive material. It will not be possible to save here, since high-quality glued laminated wood can not be cheap with respect to manufacturing technology. And if you do not adhere to compliance with all material manufacturing processes, then it will not be durable. Every spring, the facade of the house should be looked after, impregnated with special oils so that the building does not lose its beautiful color.

Criteria for the selection of a suitable project

A typical project of a house from a bar is an opportunity to save your money and time by getting ready housing in the shortest possible time.

Houses of this material can be different in height, area, layout and design. When choosing a project for a future home, the following important parameters should be considered:

-

number of people living;

-

area and location of the site;

-

seasonality of living;

-

style, number of floors, and building design.

On our site you can find contacts of construction companies that offer the service of designing houses from laminated veneer lumber. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Main stages of construction

Selection and coordination of the project. It can be typical or individual.

Construction of the foundation. Since the material for the house has a small weight, the need for arranging a powerful foundation disappears. If the groundwater at the construction site is deep, it is enough to build a monolithic foundation of 0.5-0.8 m.

Installation of the box and the roof. At this stage, high-precision assembly of the walls is carried out according to the project. Then the roof is mounted.

What is the construction of a turnkey house

The construction of a turnkey house implies the complete completion of the house building process. Finishing is carried out, summing up all necessary communications to the building, rough floors are installed according to your preferences.

Rough wiring of pipes and wires is performed , ventilation inside the ceiling.

Finishing is underway, floors and ceilings are laid, interior walls and doors are painted, sockets are installed.

Since a bar does not like the sun and moisture, it is impregnated with special oil. The timber can be varnished and painted, covered with various types of finishes.

Prices for projects of houses from glued timber in Moscow

The construction cost takes into account the house furnishing:

-

house "for finishing" - without finishing works and interior engineering communications - 25,000 rubles per m²

-

with a fine finish and all communications - from 47,000 rubles per m²

-

the most budget-friendly option “box "- from 9,000 rubles per m²

The construction of summer houses or guest houses, where permanent residence is not provided, will be fairly cheap. A home for permanent residence should be well insulated, and timber for them applies the maximum thickness.

For more information about the features of building a house from glued laminated timber, see the following video:

Quite a few construction companies operate on the market, which have a full cycle works - from woodworking to construction and sale of glued timber cottages. In the catalog, each of them has a lot of ready-made projects - you can choose and buy a house from a turnkey glued timber bar cheaply, the prices of projects of such cottages are given below.

Project "Agat"

Small in size, but very cozy house that looks great on any site. This project represents a spacious living room on the first floor, and on the second floor there are three rooms provided for under the bedrooms, a study, a nursery or a playroom.

It can be interesting! In the article on the following link read about the project at home 9 to 12.

Characteristics:

-

Total area: 94.47 m²

-

Dimensions: 7.68 x 7.68 m

-

Price: 2,189,500 rubles.

Project "Triumph"

Compact and cozy cottage with a huge living room and terrace. There is a hall on the attic floor. All rooms have access to a cozy balcony, where in the evenings you can enjoy the beauty of the Moscow region.

Characteristics:

-

Total area: 111.61 m²

-

Dimensions: 7.2 x 8.9 m

-

Price: 2,795,000 rubles.

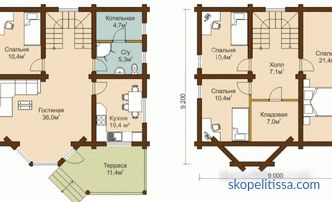

Pushkino Project

Simple architecture gives the house a special charm. The ground floor has a bedroom, a large living room, a separate kitchen, a boiler room, a bathroom and a terrace. On the second floor there are four bedrooms, a hall, and a storage room.

Characteristics:

-

Total area: 134.3 m²

-

Dimensions: 10.9 x 9.0 m

-

Price: 3,130,000 rubles.

It can be interesting! In the article on the following link read about the project at 7 to 8.

Conclusion

Construction houses from laminated veneer lumber has proven itself in harsh countries such as Canada and Finland. Houses made of such material under the key are constructed much faster than classic log cabins, are practical enough for living, do not shrink, have excellent heat and sound insulation and look very nice. In such a home, a small family and several generations under one roof will feel cozy and comfortable.